|

|

|

|

|

|

|

|

|

|

|

Slackerous Maximus

Join Date: Apr 2005

Location: Columbus, OH

Posts: 18,232

|

Setting concrete forms against rockery?

I'm looking for advice on how to set forms for a concrete staircase against rockery. The rockery walls curve up parallel to each other, and I would like the stairs to met up with the rock surface. Anything to avoid manually carving the ends of the forms to meet the rock would be nice. Maybe something with expanding foam insulation, then carve the foam?

I've seen this done in number of places in my neighborhood, but mostly with older houses. I know its going to be lots of manual labor, but its a small stair case, I don't mind. It creates a really cool look. Any thoughts, ideas, alternatives would be most appreciated.

__________________

2022 Royal Enfield Interceptor 2012 Harley Davidson Road King 2014 Cayman S, PDK Mercedes E350 family truckster Steam locomotive. Yes, you read that right. |

||

|

|

|

|

Slackerous Maximus

Join Date: Apr 2005

Location: Columbus, OH

Posts: 18,232

|

To be more clear, the rockery is not tightly stacked 'dry stack' rocks. Its big 1 and 2 man boulders. Very uneven.

__________________

2022 Royal Enfield Interceptor 2012 Harley Davidson Road King 2014 Cayman S, PDK Mercedes E350 family truckster Steam locomotive. Yes, you read that right. |

||

|

|

|

|

The Unsettler

|

Are you looking to butt up directly against the boulders?

Won't that create an issue with expansion? I don't know, the thought just popped into my head.

__________________

"I want my two dollars" "Goodbye and thanks for the fish" "Proud Member and Supporter of the YWL" "Brandon Won" |

||

|

|

|

|

Cogito Ergo Sum

|

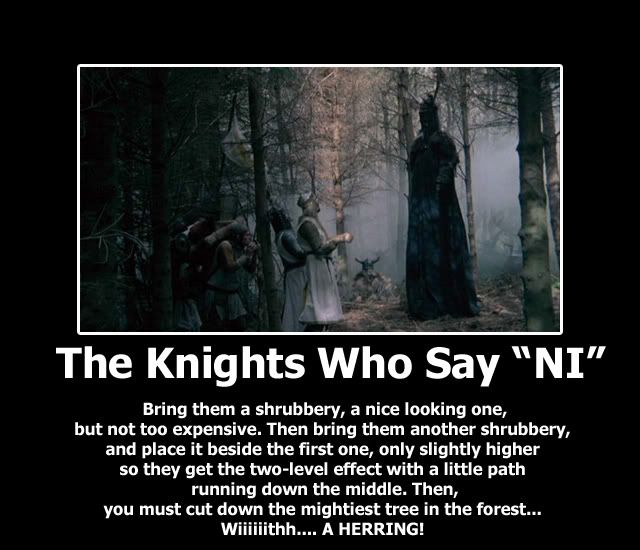

Is a rockery kinda like a shrubbery?

|

||

|

|

|

|

Slackerous Maximus

Join Date: Apr 2005

Location: Columbus, OH

Posts: 18,232

|

__________________

2022 Royal Enfield Interceptor 2012 Harley Davidson Road King 2014 Cayman S, PDK Mercedes E350 family truckster Steam locomotive. Yes, you read that right. |

||

|

|

|

|

The Unsettler

|

I think you'd do better dismantling sections of that. Pour the stairs "under" it then put the rocks back on top.

__________________

"I want my two dollars" "Goodbye and thanks for the fish" "Proud Member and Supporter of the YWL" "Brandon Won" |

||

|

|

|

|

|

Used & Abused

Join Date: Feb 2004

Location: Sebring, FL

Posts: 924

|

Why not use the spray foam to glue the form boards in place? Experiment with different solvents though as the foam is a sticky mess to clean up.

__________________

83 - 944, daily driver 62 - VW Karmann Ghia, never moving restoration "Oh Bother," said Pooh, as he chambered another round. |

||

|

|

|

|

Registered

Join Date: Apr 2005

Location: outta here

Posts: 54,460

|

I don't know how high your stairs will be but consider this: When you pour them, you can figure that the pressure at the bottom from the concrete pushing out on the forms will be around 150 pounds per square foot, for each foot of height. The actual pressure depends on a lot of things but you can use this as a general guide. That sort of pressure will not be kind to any gaps that you might fill with foam.

I'd remove a section of the wall, pour the stairs, then build the wall back on either side. Or, build the stairs out of rock, mortared in such a way as to look like a dry stack wall. JR |

||

|

|

|

|

Registered

Join Date: Oct 2005

Location: Magnolia State

Posts: 7,548

|

Build the forms with the ends against the rock open. Then staple heavy mil visclean to the inside of the form to seal off the ends against the rock. Pour concret then trim away visclean when you remove the forms.

CAVEAT: I have no clue as to what I'm talking about (obviously  ) )

__________________

Jim 1987 Carrera 2002 BMW 525ti 1997 Buell Cyclone cafe project 1998 Buell S1W: "Angriest motorcycle I've ever ridden." |

||

|

|

|

|

MAGA

Join Date: May 2004

Posts: 10,806

|

I would probably do as Jim suggested and justlay some plastic sheeting against the rocks to keep the concrete from locking into the rock too badly. Another way would be to lay a peice of thin flexible plywood up against the rock wall which would leave an irregular gap which could then later be filled with some mortar.

__________________

German autos: '79 911 SC, '87 951, '03 330i, '08 Cayenne, '13 Cayenne 0% Liberal Men do not quit playing because they get old.... They get old because they quit playing. |

||

|

|

|

|

Registered

Join Date: Jan 2003

Location: the beach

Posts: 5,154

|

I'm not quite sure what the walls look like; a pic would be nice. Anyway, I would just make forms for the risers. It's not that hard.

You can make a form for each riser by using 2 overlapping lengths of plywood that are the length of the riser. If you butt up one side against a rock, you can trace the shape of the rock onto the plywood by moving something like a ruler along the rock, while drawing the same shape on the plywood on the other side of the ruler. Cut along the line. When both ends are cut, adjust them so they are the exact length they need to be, then attach the two pieces of plywood to each other. You'll probably want the face of the riser to not have a step in it, so the two pieces can act as a template for the final single piece of plywood form. Attach the forms with metal stakes, but make sure you'll be able to remove the stakes after the concrete sets. The forms will want to bow out in the middle, so have a stake in the middle. Making forms may be a little time consuming, but it will make the job go much smoother in the long run.

__________________

Charlie 1966 912 Polo Red 1950 VW Bug 1983 VW Westfalia; 1989 VW Syncro Tristar Doka |

||

|

|

|