|

|

|

|

|

|

|

|

|

|

|

Registered User

|

Torque for strut, ball joints etc (replacing steering knuckle)

Hi All,

Details are in a previous post, but basically one of the tie rod ends on my 924S and the 'steering knuckle' had become the same piece of metal (they'd somehow welded themselves together). It proved impossible to separate them so I've managed to get a replacement steering knuckle. By Steering knuckle I mean the part that the hub/wheel bearing; caliper, tie rod end, ball joint, and bottom of the strut all bolt to. I'm planning to swap the new part in over the weekend and have a couple of questions (I've looked at a few threads but still have some unanswered questions): 1. I think I'm right in saying it's fine to take out the eccentric bolt (having marked position on the strut) and the other bolt that attach the strut to the knuckle without any risk of injury because of the springs (the springs are compressed by the strut assembly, right). Is this correct? 2. How tight should all these bolts be when I reassemble it all. It would be good to know torque values for the eccentric and other bolt at the bottom of the strut, the bolt holding the ball joint to the knuckle (it's a 924S so has the steel control arms), the bolts holding the caliper on, and the nut on the top of the tie rod end. 3. Does anyone recommend putting any kind of grease or compound onto the tapered part of the tie rod end to stop it seizing in future, or was I just very unlucky to experience the trouble I did? I am really hoping these bolts come out without too much of a fight as I'm very keen to drive the car - I've had to wait 2 weeks for the part to be delivered due to (not very much) snow, and it took me a week or more to work out the original part was never coming out. Thanks in advance for your help folks. Mike |

||

|

|

|

|

Custom User Title

|

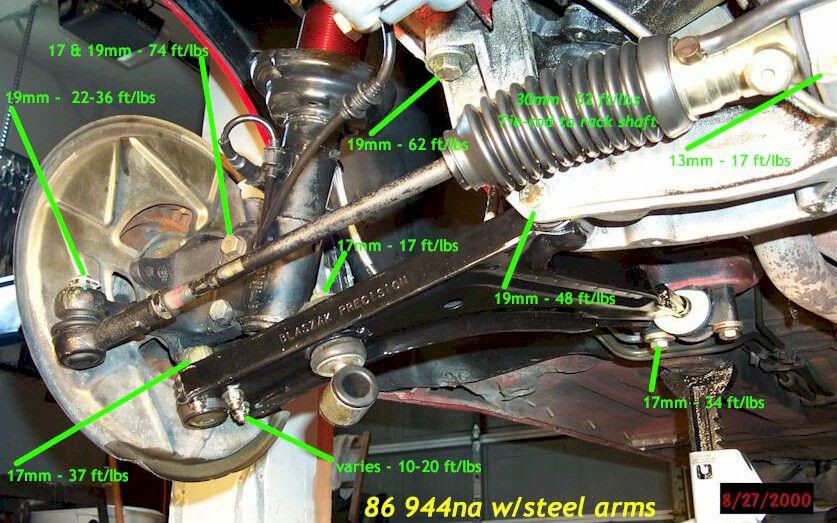

1) Yeah, the springs are compressed in the strut assembly and you can safely remove the assembly from the car.

I've tried marking the eccentric when I removed the assembly but it just didn't work for me - I wasn't able to put it back together precisely, so I played it safe and got an alignment. In your case, you're installing a new tie rod so I'd think you'd really have to get it aligned. I would mark the bolt then get it as close as possible, but then take it and get an alignment anyway. 2) The torque values for the ball joints and what not are covered in Clark's procedure: Control Arm Replacement and the struts: Strut Removal and Replacement I didn't see any torque values for the tie rod ends. What I always do - because I have the car aligned after wards - is I just make the bolts "tight" and leave the actual torquing to the alignment shop (who's gonna have to loosen them to set the alignment, anyway). 3) I've never had a problem getting a tie rod off like you, so when I install one, I don't use any special grease or whatever. I'm guessing your problem was caused by a minimum wage tech at an alignment shop humongously over-torquing the nut - probably a reaction to being bit in the butt by having not torqued something properly.

__________________

83 944 NA - Black on black 86 951 - Red - SOLD 7/21 16 Ford Expedition He who hesitates is lost. |

||

|

|

|

|

That Guy

|

__________________

Jon 1988 Granite Green 911 3.4L 2005 Arctic Silver 996 GT3 Past worth mentioning - 1987 924S, 1987 944, 1988 944T with 5.7L LS1 |

||

|

|

|

|

Registered User

|

Thanks guys, that's really helpful, especially that photo TechnoDuck.

Temporarily forgot to check Clark's. Mike - think it might have been overtightened, but it was also possibly the original (the nut was the type you put a split pin through); saying that on the replacement part there was one with the same nut and it came off very easily. I'll get an alignment done pretty soon, but will try to get it close enough to drive there OK. Hopefully get this sorted this weekend. Mike |

||

|

|

|

|

Registered

|

Hi ,if you put grease on that taper prior to assembly, it won't tighten up properly

__________________

1986 924S bought new. Now used for AutoX and street. Chipped, throttle cam, highflow filter in original airbox/snorkel, 14mm rear sway Hyundai Ioniq hybrid daily driver Vindicator Vulcan V8 spyder, street legal sports racing car (300hp,1400 lbs kerb weight) used for sprints on circuits, and hillclimbs |

||

|

|

|

|

Toofah King Bad

|

FYI, none of the self locking nuts should be reused.

__________________

» 1987 924S Turbo - Got Boost? « "DETERMINATION. Sometimes cars test us to make sure we're worthy. Fix it." - alfadoc |

||

|

|

|

|

|

Registered User

|

new problem

Thanks for all your help guys. Made good progress today in getting the old part off (lots of swearing at bolts, and a bit of sawing nuts off).

Was happily putting the replacement knuckle on, dreaming of going for a drive shortly, when I got stuck putting the bearing on. It seems that the threaded section of the spindle is a different size from the one I took off. The nut with the allen bolt on it is slightly larger than the threaded part of the spindle, and the 'new' spindle looks like it has a thread very similar to the wheel studs. The one I took off had a finer thread (you'd have to turn it more times to move the same distance along the spindle if you see what I mean. I've had a look at the pelican catalogue and can see only one locking nut. As far as you know, are there 2 different types of spindle? the new one has all the bolt holes in the same place. And any idea if nuts for the one I've just put on are very available? Cheers, Mike |

||

|

|

|