|

|

|

|

|

|

|

|

|

|

|

Registered

|

986 2.7 Camshaft Deviation - Wear versus Actuator?

I recently got the dreaded check-engine light associated with camshaft deviation. The car is a 2001 base model (2.7) with about 135K miles. I've owned the car for about 5 years.

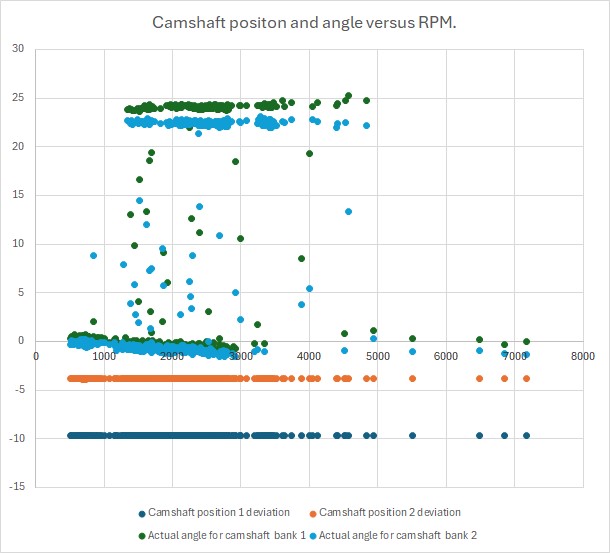

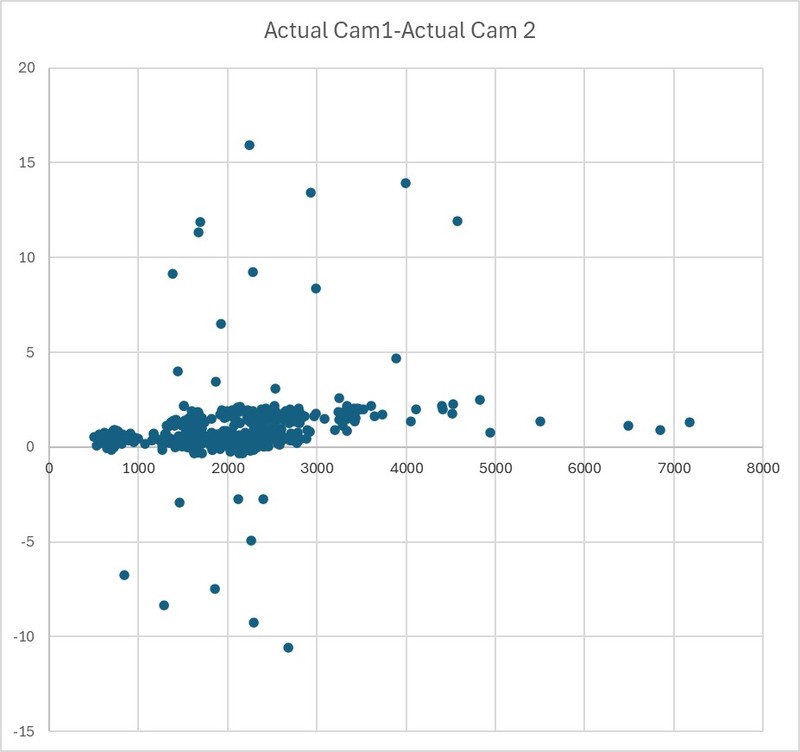

Of course it occurs just before my car's inspection is due. So I plugged in the Durometric tool, which showed the code P1341 (Porsche fault code 174 -camshaft adjustment bank 1 below limit value.) After the car was warm, I used the Durametric to activate the camshaft solenoids while at idle. - When I activated the bank 1 solenoid, nothing happened. - When I activated the bank 2 solenoid, the engine's idle got very rough. Next I took the Durometric and started data logging and took the car through my test loop, which is about 50% secondary roads, and 50% highway with a couple of engine pulls to redline on the entrance ramps. I pulled the data out to Excel to see what is going on. First I compared the two camshaft positions to the the engine's RPM.  Than I compared the 2 sides to each other by subtracting the cam2 angle from the cam1 angle for each data point.  In both cases, it seams clear that camshaft 1 is generally about 2-3 degrees higher than camshaft 2, especially when they jump to the ~23 degree setting. Also the "Camshaft position 1 deviation" is obviously about -9.66 degree, but that seems to be more of a flag value that is set rather than a specific measurement. It stayed consistent throughout the test across all of the different engine conditions. The camshaft position 2 deviation is -3.86 degrees, and also consistent in all phases of operation. Never the less, it seems like the camshaft 1 solenoid system isn't working (given the test at idle) Is it possible and worth-while to replace bank-1 solenoid actuator to see if that fixes the problem, before I start down the path of pulling the engine and replacing all of the chains, rails, etc?

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|

|

Registered

Join Date: Jun 2018

Posts: 421

|

Your logic seem sound to me. At what point do they recommend replacing the chain guides, deviation-wise?

Sent from my SM-S938U using Tapatalk |

||

|

|

|

|

Registered

|

I had the oil tested a few years ago, and it was nominal. I've also been cutting open the oil filter after removal, and there haven't been colorful specs in it.

I figure I'll drain the oil and have it checked again to see if there has been any change, and examine the filter again. In the meantime while I'm waiting for the test results I can replace the bank 1 acccuator to see if it fixes the problem. If it fixes the problem, good. If it doesn't, or the oil and filter suggest excessive wear, all that I've lost is a couple of weeks.

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|

|

Registered

Join Date: Nov 2008

Location: Sanford NC

Posts: 1,459

|

Have you looked at this https://www.youtube.com/watch?v=Nf77Nu2PMnI

An hour long discussion of camshaft deviation and what can cause it and even differences between 3 and 5 chain engines. You have a 5 chain with the most complexity. |

||

|

|

|

|

Registered

|

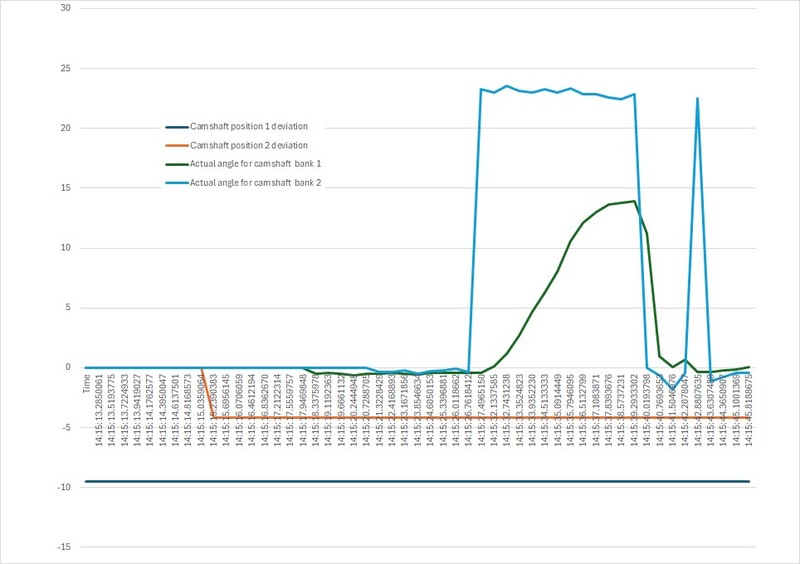

Yes I did see that video. Over on the 986Forum, the question came up of the data points versus time. Here's the data arranged that way.

It definitely seems like bank 2 is not advancing as much as bank 1. I guess the variocam system advances the intake cam by 13 cam degrees (or 26 crank degrees. I'm guessing the system measures everything in crank degrees). So the bank 1 intake cam appears to have lost about 1 degrees of advance, while bank 2 seems to have lost about 2 degrees of advance. So maybe bank 2 is the real problem(?). Or is it that both sides are retarded (i.e. 1/4-1/2 degree of wear on the tensioner ramps for the long chains, or the chains themselves), in addition to 1-2 degrees of wear on the variocam ramps? Either way, I'm going to replace the variocam ramps on both sides while I'm under the car.

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman Last edited by jluetjen; 10-29-2025 at 07:15 PM.. |

||

|

|

|

|

Registered

|

Disclaimer -- I've got the adjuster ramps, seals, cam adjustment tools, etc. on order. I'm also going to inspect the oil filter and get another oil test done.

Original problem statement: Check engine light (camshaft deviation) just as the car is due for its annual inspection. My initial reaction?    ... And then then I ( like many Porsche owners) was going spend the $,$$$ or potentially $$,$$$ to have the engine dropped and everything replaced, or worse sell the car for $ with the "check engine" light glowing. Upon further reflection, I wonder if I was being too binary about the experience. Sure. Ramps can fail and clog up oil passages. But let's give Porsche a little bit of credit. Not every car is a worst case. I also don't know if the ramps had previously been done on the car. For example, the IMS bearing had been replaced, but there was no clue of this nor a clutch replacement in the Carfax history. Assuming that I don't see chunks of plastic in filter -- I think I may just re-align the cams, check everything again with the Durometric while I put the required 60 miles on the car and submit it for it's inspection. If the fault was due to "normal" wear, and there is adjustment left, and the check-engine light doesn't come back on, it should be fine for the immediate future. All of this being said, since I've already paid for the tools and parts, I'm still going to take the cams out and replace the ramps, etc. But I may do it next spring when the weather is warmer and I have my 911 to drive around in. As usual, I'll continue to post my findings and results on this subject on this thread.

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|

|

|

Registered

|

I finished some other projects on the car yesterday, and repositioned it so that I can now work on the engine. Before I unplugged the battery, I plugged in the Durometric again and this time just data logged as I rev'd the engine from idle up to at least 6000 RPM. That clarified the failure mode...

(I neglected to log the engine revs, but you can see the issue.) The bank 2 camshaft would pop right up to the advanced setting at 2500 RPM, but the bank 1 camshaft seems pretty lazy. Given enough time, it will get there, but it's significantly slower than bank 2. You can also see that when I let the engine revs fall, that bank 2 would jump to the advanced setting on the way down at 5500 RPM, and drop again at 2500 RPM, while bank 1 would barely get started. So it looks like it's definitely the actuator rather than the solenoid since bank 1's actuator is definitely getting the message, but it's just slow to respond. Alas, the actuator and solenoid are replaced as a set. Why is this a problem? I just bought a solenoid, and now I had to buy an acuator+solenoid set. I'll see if I can return the unopened solenoid. In other news, I cut open the oil filter from the last time that I changed the oil in the springtime, and found a couple (2, maybe 3) of these in the filter.  I drained the oil from the car yesterday and changed the filter again, but I haven't had a chance to open it. I also pulled a sample to have lab tested. I'll post what I find in the filter this time around in a couple of days. Right now the plan is to replace intake chain, ramps and actuator subassembly on the bank 1 side, and the intake chain and ramps on the bank 2 side.

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|

|

Registered

|

A turn for the worse!

Here's the contents of the oil filter that I pulled out of the car on Saturday.

Greenish-yellow bits everywhere! My understanding is that this is from the seals of the chain tensioner. I guess there is no avoiding it -- it's time to replace the tensioner.

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|