|

|

|

|

|

|

|

|

|

|

|

'73 911 T Targa

|

AN fittings and copper tubing

I’m working on a project where I need to connect a 3/8” copper tube to a 6AN connector.

Can I simply flare the copper tube and use an AN nut to connect to the AN connector? Both copper flares and AN flares are 30 degrees, right? |

||

|

|

|

|

Registered

Join Date: Nov 2017

Location: Qatar

Posts: 638

|

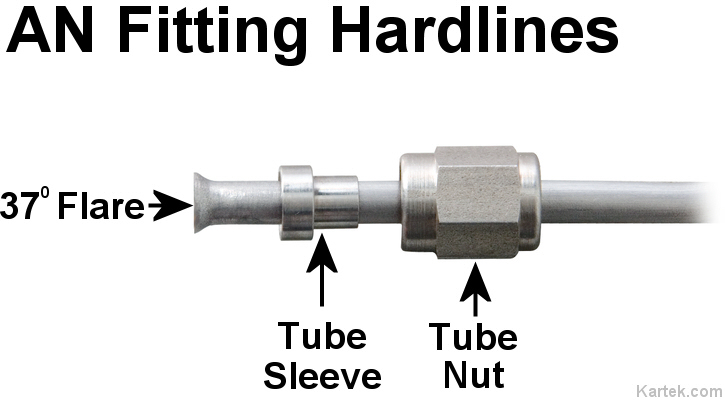

you need a sleeve and a flare nut, and a 37* flaring tool, here is a pic :

https://www.kartek.com/mm5/graphics/00000001/37-degree-flare-on-an-fitting-for-hard-line-tubing.jpg |

||

|

|

|

|

Registered

Join Date: Nov 2017

Location: Qatar

Posts: 638

|

you need a sleeve and a flare nut, and a 37* flaring tool, here is a pic :

|

||

|

|

|

|

Registered

|

I’d really try to avoid copper on automotive applications. Copper work hardens with vibration, and becomes brittle. It will crack eventually.

I’d recommend using steel or brass, or even aluminum. Sent from my iPad using Tapatalk Pro |

||

|

|

|

|

Registered

|

Agree with Andy above... copper gets brittle.

__________________

Current: 914/6 GT Conversion, Cayman Old: Many PCars + Formula Racecars |

||

|

|

|

|

Registered

Join Date: Mar 2019

Posts: 1,629

|

Or just buy the proper sized Swagelok fitting off of ebay.

I agree with the no copper. If it vibrates at all, it'll work harden. Stainless or aluminum tubing instead. Steel usually uses a 45 deg double flare connection with a different style B-nut. Or the Voss style connection if you want it period correct. |

||

|

|

|

|

|

'73 911 T Targa

|

Thanks, guys for the sage advice on the work hardening. This particular project isn't for the car, I'm building an aftercooler for my compressor, so you advice is doubly important. There's a ton of vibration in a compressor.

|

||

|

|

|