|

|

|

|

|

|

|

|

|

|

|

Registered User

|

I am getting ready to put in a new clutch/related items, but before I can do that I need to get the flywheel turned. My flywheel has already been resurfaced once (not sure how much was taken off). How many times can the flywheel be resurfaced before it's time for replacement? Is there a wear limit? If I do get it shaved again, should I have them take double off of the pressure plate since the flywheel has been resurfaced twice (if that makes any sense. It made sense in my mind).

|

||

|

|

|

|

Andrew Gawers' Dad

Join Date: Apr 2011

Location: Andrews moms house, CO

Posts: 1,901

|

Why do you think it needs to be resurfaced again?

|

||

|

|

|

|

Registered User

Join Date: Dec 2013

Location: Portland, Or.

Posts: 65

|

Not sure if all flywheels are the same. But for the 968 the pressure plate bolts to a surface which is stepped down from the flywheel surface. If you resurface the flywheel surface that the clutch disc mates to, you should take the same amount of material off the surface that the pressure plate bolts to. The distance between those two surfaces should be kept the same.

|

||

|

|

|

|

In the Fires of Hell.....

|

__________________

PCA Instructor: '88 951S - with LBE, Guru chips, 3Bar FPR, 1.3mm shimmed WG, 3120 lbs, 256 RWHP, 15 psig boost |

||

|

|

|

|

Registered User

|

It is my understanding that the flywheel should be resurfaced each time the clutch is replaced. The PO raced this car after the clutch was replaced last time so I'm assuming the flywheel has seen some abuse. I want to do it just for piece of mind. There's no point in doing all this work then finding out my flywheel is warped or something.

Quote:

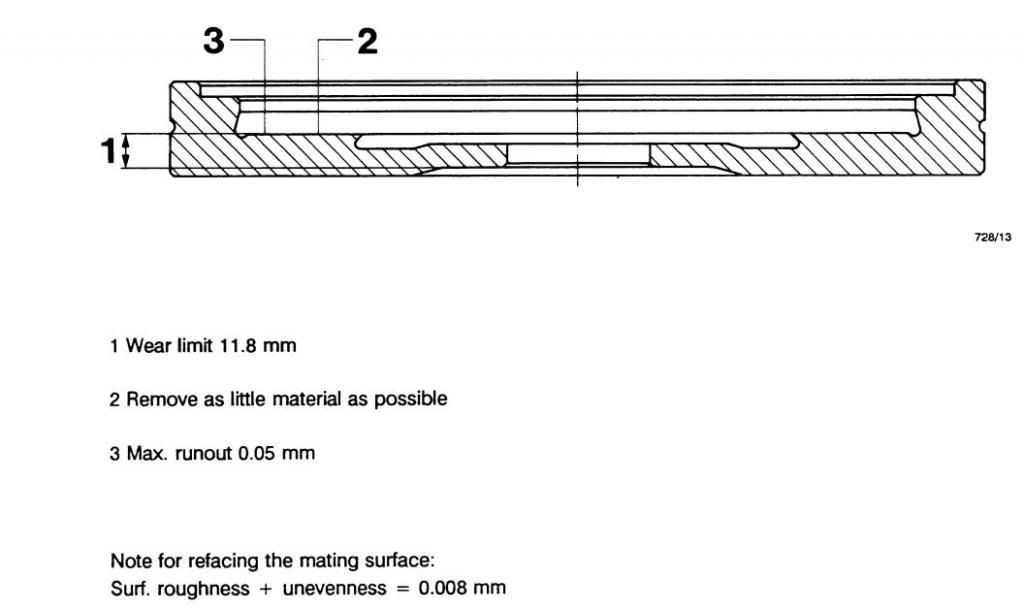

For example, let's say they took .05mm off of the flywheel last time and they take another .05mm off when I have it turned. Should I have them take .1mm off of the pressure plate so they will both have had equal amounts shaven off? Not sure what this picture is showing me? |

||

|

|

|

|

Toofah King Bad

|

Um, it is showing you how much material can be removed from the friction surface before the flywheel is out of spec (dimension one).

__________________

» 1987 924S Turbo - Got Boost? « "DETERMINATION. Sometimes cars test us to make sure we're worthy. Fix it." - alfadoc |

||

|

|

|

|

|

Registered User

Join Date: Dec 2013

Location: Portland, Or.

Posts: 65

|

If you take a copy of the picture to the machine shop doing the work, they will know exactly what it means, and can probably explain it to you.

And, I wasn't suggesting taking any material off the pressure plate, but rather to the surface on the flywheel that it bolts to (if different from the main surface of the flywheel). Again, the shop will understand what this means. |

||

|

|

|

|

Registered User

|

Quote:

Quote:

My question still remains though: if they took .05mm off the flywheel last time and take .05mm off again, should I have them take .1mm off of the area that MB968 is talking about??? |

||

|

|

|

|

Registered User

Join Date: Dec 2013

Location: Portland, Or.

Posts: 65

|

Yes, I am talking about those areas, but not on the pressure plate, but on the flywheel where those surfaces mount. In theory, you should be able to take it off of either. But, you really don't want to make a unique PP that would only work with this flywheel. If you keep the relationship correct on the flywheel, any PP would work with it, and any flywheel would work with the PP. Hope this makes sense.

|

||

|

|

|

|

Registered User

|

Yeah, I get it now. Thanks! I'm glad I asked before I ruined a $700 clutch kit... I'll have to inspect my flywheel for signs of being milled there by the shop that did the clutch last time. They half assed most of the job, but hopefully they didn't half ass that.

|

||

|

|

|

|

Toofah King Bad

|

FWIW, the FSM does not mention the additional machining MB968 says is required for the 968.

__________________

» 1987 924S Turbo - Got Boost? « "DETERMINATION. Sometimes cars test us to make sure we're worthy. Fix it." - alfadoc |

||

|

|

|

|

Registered User

Join Date: Dec 2013

Location: Portland, Or.

Posts: 65

|

Quote:

Thanks for pointing out the fallacy in my thinking. |

||

|

|

|

|

|

Toofah King Bad

|

Wouldn't say it was fallacious thinking, you were simply adding information to the discussion...

Sent from my SPH-L710 using Tapatalk

__________________

» 1987 924S Turbo - Got Boost? « "DETERMINATION. Sometimes cars test us to make sure we're worthy. Fix it." - alfadoc |

||

|

|

|

|

Registered User

Join Date: May 2012

Posts: 383

|

Back when I was working on that part of my 968, I took my original flywheel / pressure plate in to a local shop to have them assessed (about 45K miles on them), and they said they were in good condition but if I wanted them to, they would resurface the flywheel and remove the same amount of material around the mounting points as indicated above, to retain the original dimensions.

__________________

'78 924 "NA" '87 944 "S" '93 968 "SC" |

||

|

|

|

|

Registered User

Join Date: Dec 2013

Location: Portland, Or.

Posts: 65

|

Tama, I also did the same with my flywheel. On 20+ year old parts, it is hard to know what their history is. Rather than add to the offset, I paid the few extra $'s to at least keep the offset dimension the same as it was when I bought the car.

|

||

|

|

|