|

Education Time: Aluminum Brake Caliper Mounts - Galvanic Corrosion Danger

Education time! After being called a fool, censored and posts deleted it became apparent that nobody I talked with here had seen this before. Their lucky day, time to eat crow! Time to learn something new that can help keep people safe!

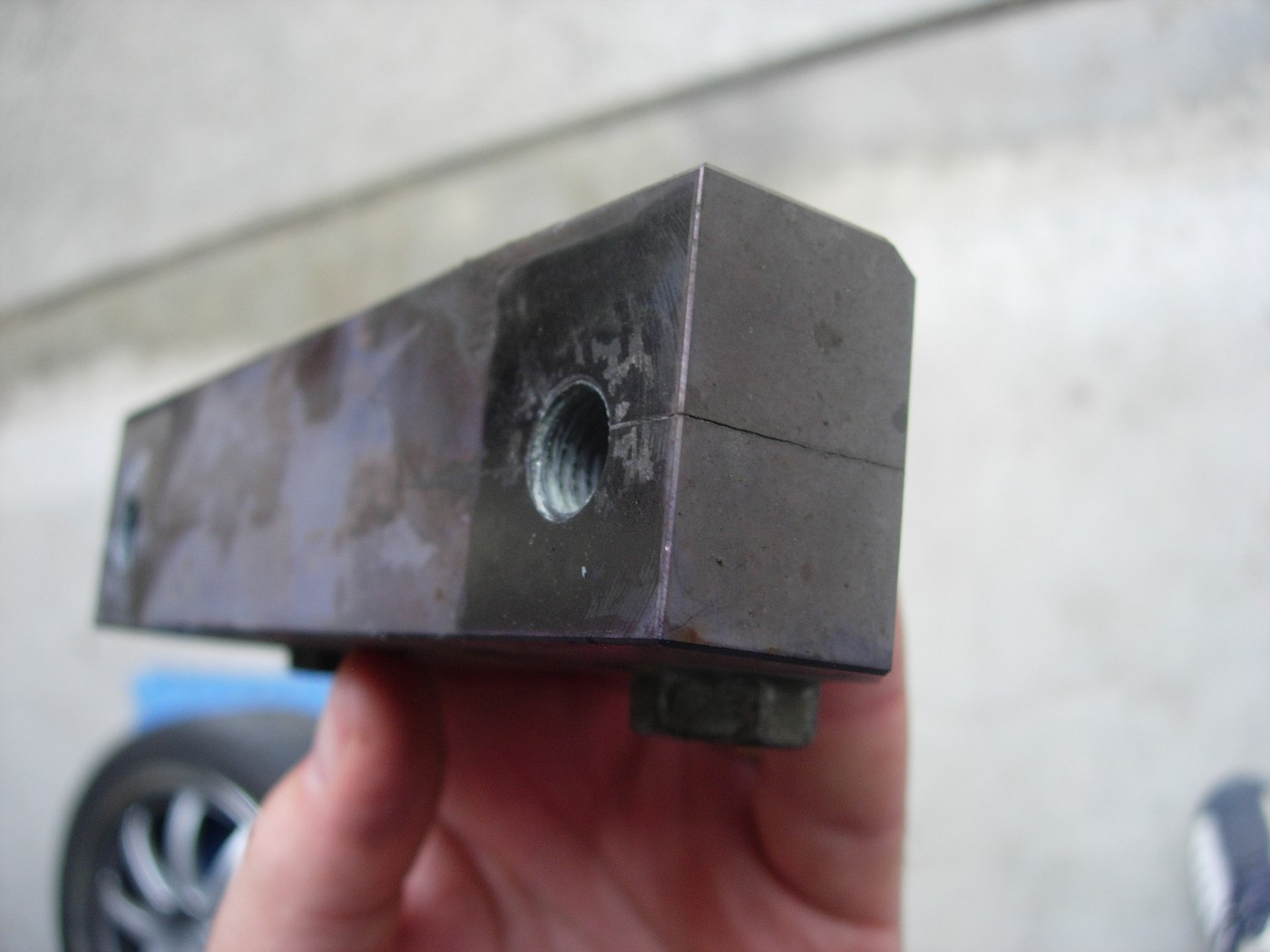

If you have these types of aftermarket pieces then please inspect them for this specific type of failure especially if you live in an area with rain and critically necessary if your area uses road salt/brine. This is a known safety issue. The cause is different nobility metals - aluminum is weaker.. aftermarket parts don't have the necessary engineering/correct isolation characteristics to prevent the condition.

The use of aluminum is prevalent in the aftermarket as it's so easy to work with and cheap. Quite unfortunate for such a critical part... not as big of an issue with iron/steel/titanium.

Galvanic corrosion:

quattroworld.com Forums: UrS4/UrS6/S2/RS2

Performance of Aluminum in Bimetallic Assemblies

Galvanic Corrosion Prevention of Steel-Aluminum Couples

The Prevention of Galvanic Corrosion in Bimetallic Assemblies

Again, this a widely known issue and more common then you might believe for street cars... hope someone here finds it useful and maybe takes an extra second to look at these parts on their car.

-Andrew

__________________

“Of the value traps, the most widespread and pernicious is value rigidity. This is an inability to revalue what one sees because of commitment to previous values. In motorcycle maintenance, you MUST rediscover what you do as you go. Rigid values makes this impossible.”

― Robert M. Pirsig, Zen and the Art of Motorcycle Maintenance: An Inquiry Into Values

|