|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Dec 2001

Location: Cambridge, MA

Posts: 44,714

|

Getting too much weld penetration?

I'm butt-welding SC flares onto my 73 this weekend. Little bit of practice yesterday.

Hobart 140, heat setting at 2, wire speed at 30, .023 wire. I cut out of a section of old quarter and clamped it back in place. I'm getting more penetration than I think I should, weld bead came through the other side...or is that good? I ground the weld down with a cutting wheel on the grinder. To the left, you can see the seam. I will be sure to grind off the underseal of both the flares and the car before welding, this was just a quick test. Should keep it at 2? After tacking both on, I plan on short beads "every now and again" to keep warping and filler to a minimum.

__________________

Tru6 Restoration & Design |

||

|

|

|

|

Registered Abuser

Join Date: Jul 2007

Location: Southwest Montana

Posts: 2,738

|

You can manually pulse the MIG gun one second bursts two inches apart and make small tacks.

Avoid putting too much heat in one area (Burn-through) On the thin stuff I place a strip of copper behind the weld it sucks the heat out. Aluminum works almost as well. Mild steel will not stick to either. It has a learning curve, be patient and practice on scrap first.

__________________

MT 930 1987 930 - Gone but not forgotten A man with priorities so far out of whack doesn't deserve such a fine automobile. I would rather wake up in the middle of nowhere than in any city on earth - Steve McQueen американский |

||

|

|

|

|

Too big to fail

|

There's no real sin in the weld bead coming out the other side, and if you're A-R you can always grind on that side, too.

Doesn't look like you have much of a weld gap; without one, you'll warp the metal easier. You should also clean off the undercoating near your weld; otherwise when it burns it will contaminate it. I use a roloc #30 or #40 sanding wheel on a small 90° angle grinder - much less aggressive and more controllable than the angle grinder. For final cleanup I use a #50

__________________

"You go to the track with the Porsche you have, not the Porsche you wish you had." '03 E46 M3 '57 356A Various VWs |

||

|

|

|

|

Registered

Join Date: Jan 2002

Location: Long Beach CA, the sewer by the sea.

Posts: 38,088

|

Quote:

I weld with as small a stick out as I can. I have to look from the side because the gas nozzle blocks my view I'm so close. Don't always believe in the gas flow setting nor the position of the nozzle on the threads. You can grind the nozzle at an angle too, if that helps. Weld in 1/2' segments and move way far way for you next weld while the previous area cools. Snip off your wire before you start each time. Wire brush the previous weld before starting your next segment. Start your puddle in the old weld, not next to it. Go slow and stay cool is my weld motto. |

||

|

|

|

|

Registered

Join Date: Dec 2001

Location: Cambridge, MA

Posts: 44,714

|

Thanks guys, with this info, I'm all set with another HOme Depot run. Did get some Rolocs Thom, need to check #.

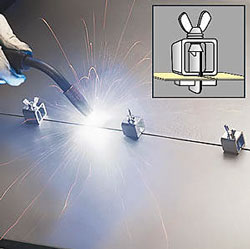

If I will get less warping with a small gap, should I use these? I've got enough to get one flare tacked on.

__________________

Tru6 Restoration & Design |

||

|

|

|

|

Registered

Join Date: Feb 2008

Location: Marietta GA

Posts: 2,560

|

Quote:

|

||

|

|

|

|

|

Registered

Join Date: Mar 2001

Location: Marysville Wa.

Posts: 22,545

|

undercoat burns fast also. keep a spray bottle of water near you. don't run any beads. after fitting the panel with spot welds every 2 inches, put another one between all of those, another one between those so you're down to about one every 1/2", then fill the 1/2" spaces with an overlapping series of spot welds. keep moving around to a cool place for the next 1/2" series. do not cool with a wet rag. just let the air do it. stop and wait if it feels too hot with your palm. after grinding smooth, put a shop light inside behind the seam and look for pinholes. pinholes allow water through to bubble the paint, so weld them up.

__________________

https://www.instagram.com/johnwalker8704 8009 103rd pl ne Marysville Wa 98270 206 637 4071 Last edited by john walker's workshop; 07-01-2010 at 01:47 PM.. |

||

|

|

|

|

Registered

Join Date: Jan 2002

Location: Long Beach CA, the sewer by the sea.

Posts: 38,088

|

Quote:

Yeah, JW has got the tacking sequence but I thought you knew that part.

|

||

|

|

|

|

Registered

Join Date: Jan 2005

Location: Minneapolis

Posts: 7,482

|

Welding is an art I never learned. I admire you guys - I'm jealous. It makes me want to learn to do it.

|

||

|

|

|

|

MAGA

Join Date: May 2004

Posts: 10,809

|

I do not have much experience mig welding large sections of auto body panel, but in general when welding thin stuff, you want to see penetration on the back side from a weld joint strength perspective. Obviously flares are not something that you need to worry about strength, but still.... I personally would be happy to have 100% penetration which will help prevent grinding through the weld leaving an unnoticed crack which will later cause rust issues or a witness line in the paint finish.

As everyone else already mentioned, you have to really jump around with very small weld beads to help control warpage even with the initial tacks.

__________________

German autos: '79 911 SC, '87 951, '03 330i, '08 Cayenne, '13 Cayenne 0% Liberal Men do not quit playing because they get old.... They get old because they quit playing. |

||

|

|

|

|

Registered

Join Date: Dec 2001

Location: Cambridge, MA

Posts: 44,714

|

Quote:

This is the best thing I've ever made. Very low stress. If you screw up, just cut away and grab a little more stock. Can't really grab another car.

__________________

Tru6 Restoration & Design |

||

|

|

|

|

Registered

|

Shaun,

I'd see what Moe is doing, he's a darn good welder (and I think his brother is even better),, nothing like free lessons

__________________

"Todd" 98 Tahoe ,2007 Saturn Vue 86 930 black and stock, 80 930 blue tracdog 91 Spec Miata (yeah I race a chick car) "life"ll kill ya" Warren Zevon |

||

|

|

|

|

Registered

Join Date: Sep 2009

Location: North of You

Posts: 9,160

|

Less wire stick-out=more penetration (counter intuitive, I know).

So if you are just tacking you can go to 3/8" or so. Longer welds should be run at 5/8" - 3/4" stickout. But you should not do long welds, as per Mr. Walkers directive. If you are using gas you want mainly argon. CO2 is too hot. |

||

|

|

|

|

Super Moderator

|

You really should have cleaned off the undercoat behind the weld. As it burns it fouls the weld and the arc. #1 rule of mig? CLEAN. CLEAN CLEAN.

__________________

Chris ---------------------------------------------- 1996 993 RS Replica 2023 KTM 890 Adventure R 1971 Norton 750 Commando Alcon Brake Kits |

||

|

|

|

|

Dept store Quartermaster

Join Date: Jul 2001

Location: I'm right here Tati

Posts: 19,858

|

Yep, I've been telling people this for some time. Straight Argon or 95/5 whatever.......a much flatter/wider bead. You have to throw everything out the window in regards to settings and just learn it but in the end it's much better for thin material work and very "clean". Sure there may be minor strength concessions but as Tim Hancock mentioned this really isn't a concern in this application.

__________________

Cornpoppin' Pony Soldier |

||

|

|

|

|

Work in Progress

|

Thanks for the confidence booster

BTW what kind of jerk would have your welder, and your homemade roto? Somebody owes you big time. . .

__________________

"The reason most people give up is because they look at how far they have to go, not how far they have come." -Bruce Anderson via FB -Marine Blue '87 930 |

||

|

|

|

|

MAGA

Join Date: May 2004

Posts: 10,809

|

Quote:

When I recently dug my mothballed 110 MIG welder out to do some "production" welding of some 1/16" wall tubing target stands, I was about to haul the old 110 welder to the dump and buy a newer bigger 220 unit when a friend asked me what gas I was using. When I said Argon, he said well there is your problem. So I bought a bottle of 75% Argon/25% Co2 mix (like we use at work for our big mig machines) and my little welder started working like a MIG should again. Next time I have to weld some "thin" steel that is not "critical" strengthwise, instead of using my TIG, I will try straight Argon vs the Argon/Co2 mix with my MIG.

__________________

German autos: '79 911 SC, '87 951, '03 330i, '08 Cayenne, '13 Cayenne 0% Liberal Men do not quit playing because they get old.... They get old because they quit playing. |

||

|

|

|

|

Registered

Join Date: Dec 2001

Location: Cambridge, MA

Posts: 44,714

|

Quote:

other way around I'm afraid.

__________________

Tru6 Restoration & Design |

||

|

|

|

|

Registered

Join Date: Sep 2009

Location: North of You

Posts: 9,160

|

CO2 also causes way more spatter.

|

||

|

|

|

|

Dept store Quartermaster

Join Date: Jul 2001

Location: I'm right here Tati

Posts: 19,858

|

Quote:

__________________

Cornpoppin' Pony Soldier |

||

|

|

|