|

|

|

|

|

|

|

|

|

|

|

Registered

|

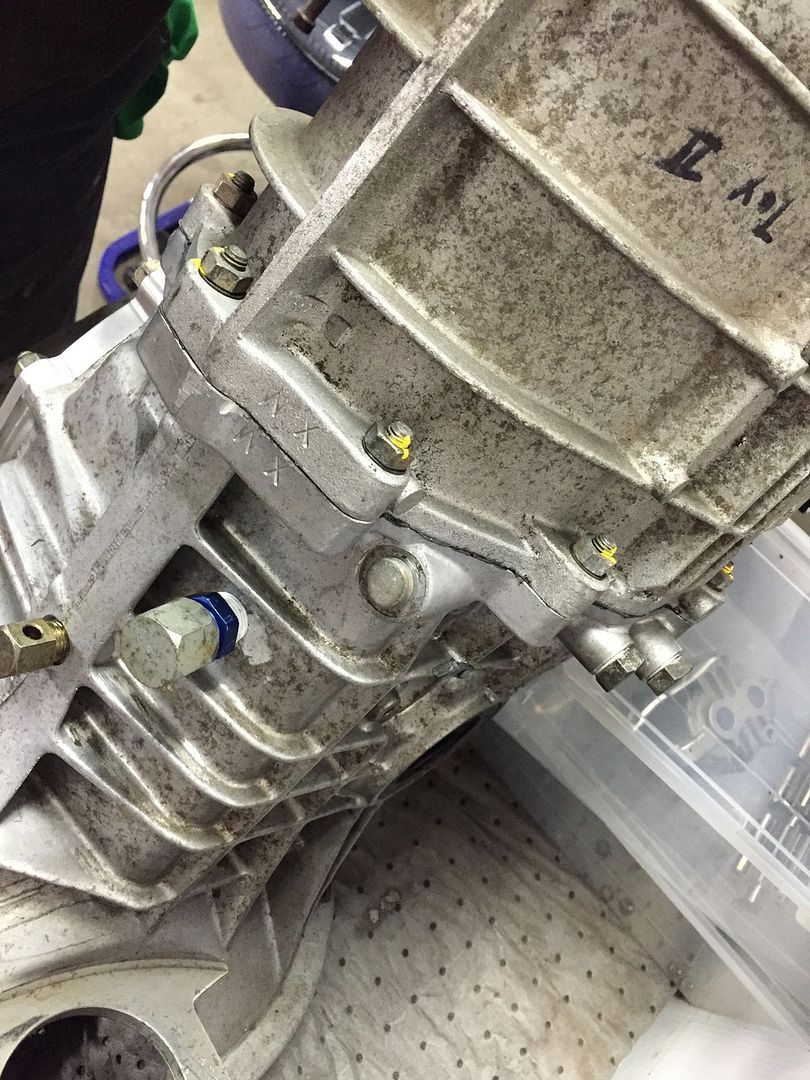

915 oil cooling locations

Just wondering if my understanding of the 915 anatomy is allowing me to understand where these oil cooler return lines are going.

1. oil hitting the leading half of the pinion prior to connecting the ring (opposite to the side of where it contacts the ring).  The oil hits the ring, at the half-way mark before connecting with the pinion.  This looks to be hitting the leading edge of the R+P where it connects the ring, which may not be good for hydrostatic pressure in the gears.  Thanks for any thoughts. The first one is mine.

__________________

1997 BMW M3 (race car) with S54 engine swap "The Rocket" 1984 Porsche 911 3.4 Carrera 1973 BMW 2002Tii 2016 Ford Focus RS |

||

|

|

|

|

Registered

|

bump

__________________

1997 BMW M3 (race car) with S54 engine swap "The Rocket" 1984 Porsche 911 3.4 Carrera 1973 BMW 2002Tii 2016 Ford Focus RS |

||

|

|

|

|

Registered

Join Date: Oct 2013

Location: Prescott, AZ

Posts: 1,062

|

The heat that is generated in the differential is due to the large difference between the centerlines of the ring and the pinion (extreme hypoid angle), so there is a fair amount of sliding on the teeth which causes the heat. It would seem that directing the cooler returns to the gears would tend to help cool them right where they are the hottest. The actual lubrication typically occurs from the ring gear dipping in the lubricant right before meshing into the pinion.

__________________

1990 964 Coupe 1986 Carrera 3.2 Targa |

||

|

|

|

|

Registered

|

So maybe I understood this incorrectly. Based on other posts, some folks felt that directly spraying cooling fluid on the R+P contact point would increase hydrostatic pressure between the gears (due to the extra oil), and thus increase wear.

If the transmission fluid level is such that the ring gear is submerged in oil before the point the R+P connect, then this kind of makes the entire hydrostatic pressure argument moot, and thus debate on the best return line location a bit pointless, and my location (first picture above) or the final picture posted, would be the best locations as they are closest to the pinion (the hottest part). Or does the ring become submerged in oil only after it meshes with the pinion?

__________________

1997 BMW M3 (race car) with S54 engine swap "The Rocket" 1984 Porsche 911 3.4 Carrera 1973 BMW 2002Tii 2016 Ford Focus RS Last edited by gliding_serpent; 07-04-2015 at 08:24 PM.. |

||

|

|

|

|

Registered

Join Date: Nov 2010

Location: SoCal

Posts: 759

|

The 915 ring & pinion gears are not hypoid, as the rotating axis (centerline) of the two gears intersect.

__________________

Jon B. Vista, CA |

||

|

|

|

|

Registered

Join Date: May 2003

Posts: 3,346

|

IMO the reason to cool the gearbox is to keep the overall temp under control. If the tranny gets hot the case expands and the gear alignment gets out of whack increasing the wear and causing shift problems. So where the oil goes in and out doesn't matter much.

__________________

72 Carrera RS replica, Spec 911 racer |

||

|

|

|

|

|

Registered

Join Date: Nov 2010

Location: SoCal

Posts: 759

|

Quote:

If you are using oil as a cooling medium, then the best place to direct it is immediately after the gears mesh. In a 911, that would mean under the pinion gear. The oil at the bottom of the transmission will obviously be hotter than oil that has just passed through an external cooler.

__________________

Jon B. Vista, CA |

||

|

|

|

|

Registered

Join Date: Nov 2010

Location: SoCal

Posts: 759

|

Quote:

The operating temperatures of the steel gears and differential will be much greater than the alloy case, so will offset the different expansion rates of their materials.

__________________

Jon B. Vista, CA |

||

|

|

|

|

Registered

|

Below is what I am talking about hydrostatic pressures. Hayden weighs in. Also note that the factory oil cool enters in a location after the r+p contact/unmesh.

To answer my own question, the transmission oil fill line is about mid case,or mid pinion. Now, with all the turbulence of fluid, who knows the real world fluid level, but at full song, it is a safe bet to be between fill level and just touching the base of the pinion teeth as they unmesh with the ring gears. The faster the transmission spins, the lower the effective level. Thus haydens concerns below are probably real if not deal breakers, especially at very high rpm. My oil entry location to the passangers side of the pinion from the top (see a above) should be fine. Quote:

__________________

1997 BMW M3 (race car) with S54 engine swap "The Rocket" 1984 Porsche 911 3.4 Carrera 1973 BMW 2002Tii 2016 Ford Focus RS Last edited by gliding_serpent; 07-05-2015 at 04:25 AM.. |

||

|

|

|

|

It's a 914 ...

Join Date: Jan 2008

Location: Ossining, NY

Posts: 4,747

|

I've read different opinions on hydrostatic pressure and gear meshing. I looked into this a few years ago when I added oil cooling to my 901 box, to determine placement of the oil jets I set up as oil returns after the cooler. I read a few warnings about hydrostatic pressure wearing the gear faces. Then I read another opinion that made sense to me - that hydrostatic pressure occurs when you force oil into a confined space where pressure builds, like the gears in 911 oil pumps. Tranny gears don't have this situation because the oil can always squeeze out the sides of the gears where the teeth mesh. In the end, I couldn't find enough information about gear wear fromhydrostatic pressure, so I wound up not worrying about it. I'd be curious to hear from any tranny experts hear if they've observed it though.

Scott |

||

|

|

|

|

gearhead

Join Date: Nov 2007

Location: Loverland, CO

Posts: 23,565

|

Quote:

Look at how the factory did it on the 3.2 Carrera. It returns from the side. Cooler oil is the important part. Location is splitting hairs IMO. Also keep in mind on a 911 it is the gears that can get starved, esoecially 5th. The ring and pinion has a ton of oil on it due to orientation and acceleration forces. Look at a GT3 Cup. The cooler return is in the Tailcone to feed the spraybar and hollow shafts. The ring and pinion doesn't get sprayed at all. The pickup is in the main housing but the return is out back.

__________________

1974 914 Bumble Bee 2009 Outback XT 2008 Cayman S shop test Mule 1996 WRX V-limited 450/1000 |

||

|

|

|

|

Registered

|

I appreciate the input guys. As I go through my build I am working to "understand" design choices, thus helping to make better design choices. I very much enjoy splitting hairs, and learning something in the meantime. It never hurts to debunk dogma along the way.

__________________

1997 BMW M3 (race car) with S54 engine swap "The Rocket" 1984 Porsche 911 3.4 Carrera 1973 BMW 2002Tii 2016 Ford Focus RS |

||

|

|

|

|

Registered

Join Date: May 2003

Posts: 3,346

|

Quote:

The transmission does a great job of circulating it's oil. The ring gear is set up like an oil pump in front of a port in the case. If you cool the oil,you cool the whole transmission.

__________________

72 Carrera RS replica, Spec 911 racer |

||

|

|

|