|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Rate Thread |

|

Registered

|

Interest in an improved oil pan which should help reduce bearing failures?

I started this over at Rennlist, but want to share it here as well. Click here for the original thread.

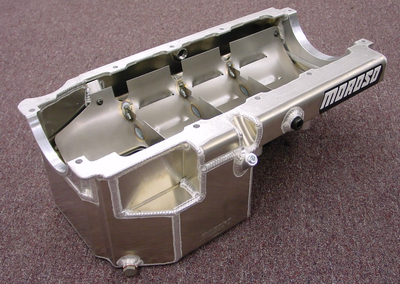

I maintain the first post at Rennlist with a reasonably up-to-date list of interested people. I will do the same here. Any interest in a new oil pan design? A new pan could be designed to help reduce windage problems and foaming problems which contribute to the infamous #2 rod bearing failures (see this thread if you need info on this too common problem). I've been in contact with a few companies who design oil pans for race cars. Several have offered to make an improved aftermarket pan which can take care of some of the most severe windage problems and potentially increases the volume a bit. These are the basic specs (subject to change depending on price and feasability): * Most importantly it will have a kick out on the right hand side to allow the oil returning from the head to escape the crank and return to the sump without following the crank around 270 degrees and foaming up. A bit like the kick out on this Moroso pan where the company logo is. This cick-out should work in conjunction with a scraper.  * Built in baflfing system with one-way ports to prevent oil from being sloshed onto the crank when braking, turning and accelereating. * Integrated crank scrapers like the stock pan, but tighter (possibly teflon blades?). * Much improved integrated windage tray with proper louvres to cut down on windage. Becuase the tray is installed in the pan it will not be necassary to split the block and intefere with its integrity and the bearing clearances to install the windage tray. . * Integrated gasket retainers to stop the gasket from pushing out.  The windage tray will sit on top of the baffles and the baffles will be welded to the tray to give it rigidity and to ease assembly. The windage tray will be bolted to threaded inserts in the pan. The diamond shape minimizes slosh and, together with the two outside perpendicular baffles, makes the trap doors more efficient as the oil outside the diamond shape will be forced into the centre of the diamond by acceleration, deceleration and cornering forces.  To get this moving we need to get 10-15 people together in a group buy. Please sign up here if you are intersted in such a pan. For now the list will be to judge interest only. If there is enough solid interest I will make a bindig list once the design is finalized. People who are interested depending on price: Pelican parts: -Gawernator - one Rennlist: -Chris White - several -Myself - one -KSira - one -ausgeflippt951 -one -Omni -one -harveyf -one -carlege -one -Nashio -one -fejjj - one -URG8RB8 -one -Jamesr6967 - one

__________________

1990 944 T: 100 000 km/63K miles, 1997 986 2.5L: 95 000 km/60K miles, Living in the trackless land of plenty! Last edited by bebbetufs; 04-26-2013 at 04:09 AM.. |

||

|

|

|

|

AFM #725

|

Definitely interested for a decent price. I could use a new gasket anyways

|

||

|

|

|

|

Banned

Join Date: Apr 2011

Posts: 683

|

#2 failures are one of two things, mainly because #2 doesn't get enough oil in the first place. That is why some have altered the oil passages to get better flow.

1.) Low oil pressure for whatever reason. Wrong oil viscosity is a big one. 2.) Coolant mixing with the oil. With that said, I believe this kind of one-off pan is expensive snake oil. Pun definitely intended. Sure crank scrapers are nice, baffles are cool, but I just don't see it making any difference at all as far as the bearings are concerned. Sounds like a misunderstanding as to what exactly causes #2 failure here. |

||

|

|

|

|

Toofah King Bad

|

Lindsey pan and pickup mod is all that is needed. . .way cheaper than what you are considering.

__________________

» 1987 924S Turbo - Got Boost? « "DETERMINATION. Sometimes cars test us to make sure we're worthy. Fix it." - alfadoc |

||

|

|

|

|

AFM #725

|

hmm... Rasta makes a great point.

__________________

Watchdog Armory Racing AFM #725 Thanks to my 2017 Sponsors: JPH Suspension | AXO | Armour Bodies | BELL Helmets | Braven | EVLUTION Nutrition | Forcefield Armor | FunTrackDayz | Galfer | Motion Pro | MOTUL | Matrix Racing Concepts | ODI Grips | OGIO | Shorai Inc. | SPEEDMOB | Vortex | Woodcraft | Wicked Audio http://www.gawerracing.com |

||

|

|

|

|

Non Compos Mentis

Join Date: May 2001

Location: Off the grid- Almost

Posts: 10,609

|

My race car has a couple baffles added to the stock pan. That, and a cross-drilled crank are all that's needed to eliminate 944 oiling issues. Several of us 944 guys have been racing for years now with no bearing failures.

|

||

|

|

|

|

|

Registered User

|

As far as hard cornering for long periods of time, baffle would be great. Wouldn't do anything for bearing failure though. You'd want to cross-drill the crank for that. Seems like it might be a good track thing though.

|

||

|

|

|

|

Registered User

|

early cars were cross drilled. but with every additional hole along the way oil pressure is reduced. since the 2nd and 3rd rod bearing are the last, most peripheral point in the oil flow circuit, they most are sensitive to this decrease in pressure. this may or may not have been the reason the design was changed to a single hole after '84. So cross drilling should probably be combined with a different viscosity or an uprated oil pump output (a dry sump system is the only possibility I can think of)

|

||

|

|

|

|

Registered User

|

Quote:

|

||

|

|

|

|

Just thinking out loud

Join Date: Nov 2001

Location: Close by

Posts: 6,885

|

Never had a problem with oil pressure on my 83, except for when I knocked a hole in the oil pan and later when the cam tower gasket blew. The rod bearings looked brand new after 140K miles.

I'd like to see a show of hands on rod bearing failure from the factory cross drilled crank crowd.

__________________

83 944 91 FJ80 84 Ram Charger (now gone) |

||

|

|

|

|

Registered

|

I'm sorry guys but the #2 failure is not only pressure or flow related. It is a compound problem whith multiple sources. Please keep in mind this is primarily for heavily tracked and tuned cars .

*Cross drilled crank engines have failed. *The LR baffle does not keep the oil from sloshing forward and onto the crank during heavy breaking. One known reason for the failures is foaming of the oil. 1. The oil pump is not designed for high RPM and cavitates above ~ 4800 rpm. 2. There are no oil returns which don't go via the crank, 3. breaking and accelerating throws oil onto the crank, etc. Please read the thread before you conclude that this is snake oil. It definitely isn't. And by the way, I'm only doing this because I see the need for one for myself, not to make money.

__________________

1990 944 T: 100 000 km/63K miles, 1997 986 2.5L: 95 000 km/60K miles, Living in the trackless land of plenty! Last edited by bebbetufs; 04-24-2013 at 05:15 AM.. Reason: Too low number for when oil pump cavitates. I put 4200 when it should be ~4800 |

||

|

|

|

|

Registered User

|

|||

|

|

|

|

|

Banned

Join Date: Apr 2011

Posts: 683

|

Quote:

Sloshing oil onto the crank? Not going to cause a bearing failure, I'd love to hear your reasoning for this. Point #1 - bull****. Simple bull****. If the oil pump cavitated at 4200+ rpm we would see oil pressure SEVERELY drop above those rpm, we simply do not see this happen. A cavitating pump produced little or no pressure, the 944 EASILY holds 5+ bar above 4200 rpm. Point #2 - what???? Oil returns are gravity fed from the top end down to the pan, you're entirely entirely wrong here. And point #3 - again I would love to hear how oil getting splashed onto the crank is going to cause bearing failures. Respectfully waiting some real proof. I honestly think you either A.) Really want one of these snake oil pans, and cant afford to have one made as a "one off" for yourself, or B.) Do indeed have some ,money to be made off these. |

||

|

|

|

|

GorillaFoot

Join Date: Jul 2011

Location: largo, FL

Posts: 369

|

We also have quite a few good oil selections with anti-foaming properties....

I like any innovative ideas that will keep my engine from destruction, but I really think it's all been covered now- baffles, windage trays, scrapers, better quality oil, etc. It's all out there and relatively cheap. The most difficult part in any of this is the removal of the oil pan, so why re-invent the wheel? Making a custom oil pan to house all this stuff, simply to have a kick-out, would make the project unreasonably expensive. Never heard of a kick-out before and never heard NOT having a kick-out is the reason for bearing #2 failure. Like the effort, but it seems like expensive overkill.

__________________

1989 951 Track car. Cayman GT4. Suncoast PCA Chief Tech Inspector. |

||

|

|

|

|

Non Compos Mentis

Join Date: May 2001

Location: Off the grid- Almost

Posts: 10,609

|

Yes, but......

The local race shop measured the oil pressure at all four bearing journals at high rpm and found #2 to be the weakest (duh!), but #3 was not far behind. Drill only #2, and the engine will last just a bit longer until #3 lets loose. In our class (SCCA's ITS), nobody has yet suffered a bearing failure after the local 944 race guru assembled it. |

||

|

|

|

|

Banned

Join Date: Apr 2011

Posts: 683

|

Actually if you drill ANY of them the average oil pressure across all of them will fall.

Think of it this way; if you put your thumb over the end of a garden hose pressure rises, you get a stream. This is the undrilled feed. Remove your thumb and the pressure drops, this is the drilled feed example, you are raising the surface area of the escape route of the oil, therefore pressure drops. Honestly I worry the drilling will make things worse over thousands of miles. |

||

|

|

|

|

Registered

|

I'm sorry if I sounded a bit cross. But honestly, I'm trying to do some god here and the response I get is like acid rain....

But then again, ideas like this need to be challenged. After all I might be wrong. But then again, ideas like this need to be challenged. After all I might be wrong.When oil splashed onto the crank CAN contribute to oil failures is when the oil going to the bearings is so areated the oil film can't bear the load and metal to metal contact occurs. The oil pump is designed for street use. That means short burst to top RPM. It is not designed (geared) for sustained high RPM as race cars see. It would likely make it less effective at low RPM were street engines operate most of the time. As far as I know the cavitation issue has been confirmed independently by both Chris White and Rogue Tuning. I did get the numbers wrong though. It should be ~4800, not 4200RPM as I first stated. Yes the oil returns are gravity fed, but they drop into a very shallow pan on on the upward rotating side of the crank. The oil will land on the oil pan, where it has nowhere to go, splash onto the crank. Spin around with the crank for 270 degrees and then get scraped off by the scarper in the oil pan and the plastic tray on the opposite side of where it came down. At this point it will have been whipped into a frothy foam. If you don't believe me please take a close look at your engine from the front. The oil returns are on the passenger side. The crank spins clockwise. You can only take my word for it that the oil enters the pan at it's most shallowest point (were it is closest to the spinning crank). The oil pan is too shallow. Ask yourselves why Porsche would use an impossibly thick 10mm gasket? It was an attempt to create more space and volume in the sump, a cheap fix to a design problems caught too late in the process. The kick out will be on the right hand side, right next to where the oil returning from the head hits the pan. The oil will be blown into it and returned directly to the sump, instead of spining around with the cranck. Should create a small HP gain at high RPM as well as drastically reduce foaming. The baffles available on the market will defnintely improve the situation and help reduce side to side slosh. Still we can benefit the most from reducing front to back slosh. When do most bearings spin? From what I have found scouring the forums it seems to be when accelerating hard out of a turn after heavy braking (this is my impression, I don't think any number exist to back this up). This is when the oil has been sloshed forward, beaten to a froth by the crank, sloshed back again during acceleration creating more froth, then this mixture of oil and air is pumped to the bearings when the need for a strong oil film is most critical. It does not help that the pump is already cavitating..... It may be that the problem is not so great with the NA cars as with the turbos though, as they generate higher loads in every sense. I completely agree that the oil pan is not the reason for the failures, but a good oil pan can help reduce some of the problems and together with some other important measures (of which I don't belive cross drilling to be among the most important) it should significantly reduce the risks AND increase performance due to better windage control. When carefully studying the engine design this makes a lot of sense, enough to convince me at least. That's why I'm doing this, because I am absolutely convinced it will be an improvment and I thought others could benefit from it as well. Of course I'm not out to make money. I live in Norway....there is no market over here. I admit I want to go to the track and go flat out without worrying about the bearings, and yes a group buy would make it cheaper for me, obviously. But, it will be far easier and cheaper for me to just modify my existing pan, which I will do anyway to get the car ready for the season.

__________________

1990 944 T: 100 000 km/63K miles, 1997 986 2.5L: 95 000 km/60K miles, Living in the trackless land of plenty! Last edited by bebbetufs; 04-24-2013 at 05:17 AM.. |

||

|

|

|

|

Banned

Join Date: Apr 2011

Posts: 683

|

I'm just asking here, do you know know exactly how hard it is to froth up some oil? Accel and decel aren't going to do it. The real issue as mentioned above is the pickup tube mod. And as mentioned above all that stuff is available on the market already man.

|

||

|

|

|

|

Registered

|

Quote:

Preasure steadily increases with RPM, as the pump starts cavitating the pressure increase will begin to lag behind the increasing RPMs of the pump. In other words; the pump could both be cavitating and maintaing a set pressure, but it will not be operating as efficient as it should at the higher RPMs. Also, thee pressure could be fluctuating too fast for the stock oil pressure sender to pick it up or too fast for the gauge to display it while still putting the weakest bearings at risk. Again, this is theoretical only. I'm really only going on other peoples findings on this cavitation issue.

__________________

1990 944 T: 100 000 km/63K miles, 1997 986 2.5L: 95 000 km/60K miles, Living in the trackless land of plenty! Last edited by bebbetufs; 04-24-2013 at 05:21 AM.. |

||

|

|

|

|

Registered

|

Quote:

__________________

1990 944 T: 100 000 km/63K miles, 1997 986 2.5L: 95 000 km/60K miles, Living in the trackless land of plenty! |

||

|

|

|