|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Jan 2015

Posts: 118

|

Diy maf

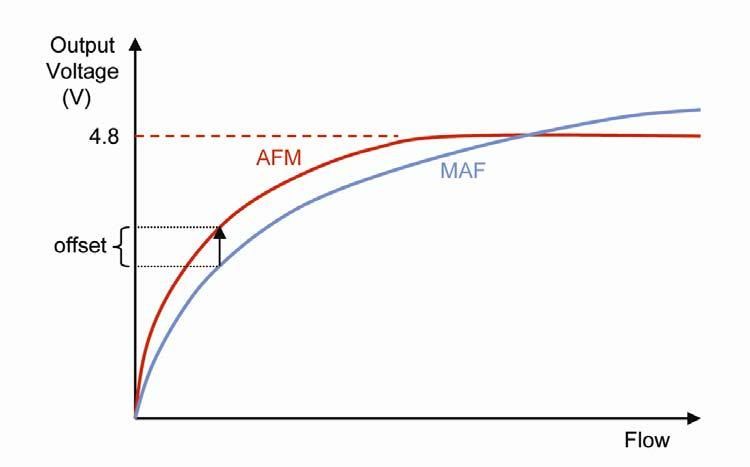

Has anybody tryed a DIY MAF maybe by identifing the Bosch sensor used in the kits? Presuming probably wrongly that the sensor just sends out a voltage reading in the same way as the AFM could this be a simpler process than we are led to believe..

|

||

|

|

|

|

Registered

Join Date: Oct 2002

Location: Boulder, CO

Posts: 1,205

|

It's been tried. You are trying to emulate the barn door's behavior and resulting voltage by inferring what the barn door would be doing by reading various signals from the MAF sensor. This is not so hard if every day was 70 degrees and the same humidity all day.

What you really need is a 3D map of the MAF reading at all expected conditions and a link from each of those points to a derived AFM voltage. You could do this with an Arduino but if you could do that you could probably afford a 968 or a Cayman S, which have a MAF already. Or will be able to when you graduate. I'd have my druthers with going standalone, or maybe wiring a VW 1.8T or 2.slow ECU to the 944, something with good self-tuning support, even then I don't think it's worth the effort given the gains. -Joel.

__________________

1987 928S4 1992 968 cabrio 2009 957 Cayenne GTS |

||

|

|

|

|

Registered

Join Date: Mar 2008

Location: Nashville, TN

Posts: 4,061

|

just save up for a few weeks/months and get the Lindsey NA-tune.

plug and play and it WORKS. it is not just a case of "voltage conditioning"...everything about how a MAF works is different than the AFM. |

||

|

|

|

|

Registered

|

You really can't beat the price on the Rogue Tune MAF Lindsey is now selling. The sensor alone is over $100. The intake pipe and harness connector is high quality and would be a lot of trouble to replicate. And the intellectual property in the chip maps and all of the dyno runs would also be a lot of trouble to recreate. Mine runs great.

|

||

|

|

|

|

Registered

Join Date: Mar 2008

Location: Nashville, TN

Posts: 4,061

|

To answer your original question though...yes, several people have tried to do this over the years, myself included, and it doesn't really work without getting into the hardware/software of the ECU.

Way easier and better to just buy the kit. |

||

|

|

|

|

Registered

Join Date: Feb 2003

Location: SF East Bay

Posts: 1,856

|

Quote:

What is your goal? I did this about 20-years ago, I'll give a summary to save you trial & error frustration. If you want more power without destroying your engine, you must do the following without skipping any steps. 1. Get chip-burner, a handful of blank 2732 or 2764 EPROM chips and a chip eraser. Or get a flashable emulator such as Ostrich. 2. Find suitable air-temp sensor. Easiest to extract factory sensor from AFM and measure its output response curve. About 10 datapoints between -10 to 110-C should be sufficient. Look up datasheets on Mouser until you find a thermistor with similar response curve to the stock unit. Buy a handful of these thermistors for $0.13/ea. 3. Figure out mounting method for thermistor ahead of MAF in intake. The mount should hold sensor firmly without allowing outside air to sneak in. Should also have connector to send air-temp signal to DME. 4. Select MAF of appropriate max flow-rate for your application. Don't pick a 600hp MAF for a 944na for example. 5. "Map" the MAF relative to the stock AFM; you can use a flowbench. This can be done by mounting the MAF inline with the AFM and logging both their voltage outputs simultanously as you flow more and more air through: AFM MAF 1.0v = 0.8v 1.1v = 0.87v 1.2v = 0.93v 1.3v = 0.99v etc.  6. Download chip-programming software. Rogue's site had some listed with pre-made chip-image definition files for 944/951 along with some transfer-functions of common MAFs on market. Pick one closest match to curve you tested in #5. 7. Dyno-tune your new chip at each flow X rpm datacell. There's about 160 data-cells on chip for fuel and 160 for ignition. Use a Mustang dyno so you can hold engine precisely inside each flow X rpm datacell as you adjust for optimum AFR and ignition in each cell. Repeat for each data cell. 8. When done, dump image to chip. 9. Build appropriate intake plumbing to hold MAF. It should match factory config with getting cold air from the fender. Plan on budgeting at least 200-300 hrs labour to do the above and about 10 hrs on dyno. Last edited by DannoXYZ; 02-05-2017 at 10:00 PM.. |

||

|

|

|

|