Quote:

Originally Posted by cabmandone

Okay. For some reason I thought I remembered seeing a jet pump in one of your pics. I'm not familiar with the pumps that use a control box. My pump is submersible and doesn't require a control box. I'd definitely keep a capacitor on hand. I've found that sometimes with a pressure switch, a good tap will get one up and working on a temporary basis. With yours having wires that got hot, I'd probably put an amp probe on the supply wires just to see what the pump is drawing.

|

I'm not sure the "control box" is really much other than a box for the capacitor and maybe a little transformer or something. I'd worried that the fried switch was a symptom more than the problem. That's why I monitored after I put everything together. No wires ever got warm. I was away from home today, but this weekend i'll do some more checking on things.

One of the things that I checked "while I was in there" was the pressure in the pressure tank. It was supposed to be 38psi (2 psi below the turn on psi of the switch). It was about 25psi. I pumped and pumped, and pumped it up until I had 38 psi. I need to get out this weekend now that all or at least most of the air is out of the system and check the on and off pressure and make sure it's right.

Quote:

Originally Posted by A930Rocket

So, do you keep the spare parts in a bag in the pump house, etc.? I had a McLean edger and always kept a spare belt tied to it.

|

Historically, I did not keep a lot of spare stuff on hand because I lived places where there were stores open 7 days a week, water came out of a pipe, etc.... Now I live in the country where many/most stores are closed on Sundays, and if I have to go to 3 different stores, one is 4 miles west, the next is 15 miles east, and then the third is 25 miles northwest. Then there's the issue that getting the water out of the ground and into the house is my problem (as well as a bunch of other stuff). I think I'm going to start keeping more spare parts around.

Quote:

Originally Posted by 3rd_gear_Ted

Your pressure switch should be controlling a load relay and not be in line with the large current surge of the motor every time it starts. If the pump starts short cycling its gonna burn up again.

|

I'm pretty sure the pressure switch is THE relay for the power to the pump.

Quote:

Originally Posted by john70t

^This.

The switch just handles the amps.

The amps are from the pumper/motor.

[we assume the electrical supply to the pump is good]

The amps from the pump motor are based on a continuous fresh supply of water and a clean pump.

That should work forever under normal conditions.

It may be supply lines blocked by minerals...or routed too ziggy from the well...or unfiltered ground water supply detriment which is chewing up the pump....

What you see burn up might not be the actual problem.

Fix the source.

|

that's a concern for sure.

Quote:

Originally Posted by DerkPerk

The over heated wires are high current draw due to a poor connection, with the actual wire connection or the contacts in the pressure switch. You covered the bases by replacing the switch and cutting the wires back. Like mentioned above, not a bad idea to get an amp clamp on the load. It always pays to be handy!

Sent from my iPhone using Tapatalk

|

I believe there was a bad connection at the switch that caused a problem, but I will be doing more checking to be sure.

failed switch. Wire #1 (1st from left) was fine, #2 was REALLY cooked, and #3 and #4 were mildly cooked.

Not my new switch, but this is what it looked like.

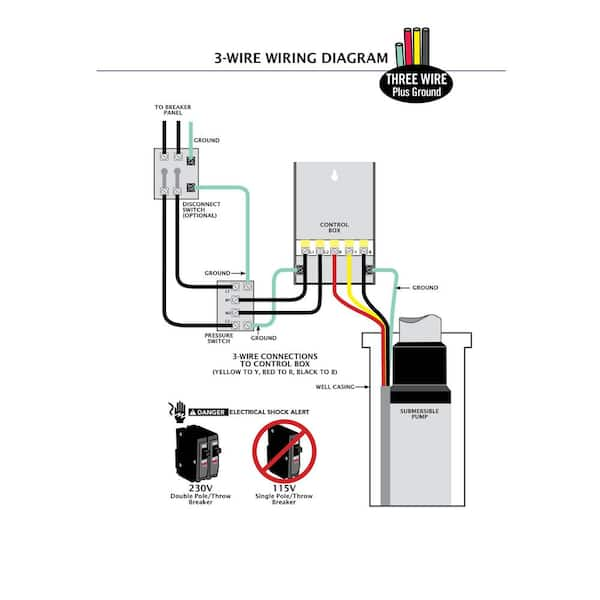

The box that I called a "control box" is very much like this. It doesn't seem like it really controls anything. It's mostly just a housing for the capacitor.

But, in this diagram, they call it a control box, so I guess I'm not the only person to call it that.