I know that we've got a bunch of tool nerds out there.

And some of you guys have been around since we knocked 2 rocks together to make fire or hit a critter with a rock to catch dinner.

What awesome, weird, cool tools do you have?

I picked up a few tools in the last couple of weeks just because...

I bought a "Ford" T-1917 wrench which was for Model Ts and/or possibly Ford tractors. Wow, this thing is crazy. It's got 2 different sized ends, sort of. The flats aren't remotely parallel, and the "meat" on the 2 prongs varies a lot. The back has each end labeled, and the labels are "1" and "2". I think the wrench would roughly fit a ⅝" (or maybe 11/16") and ¾". But the larger sized end measurements at the base of the flats is 0.71" and at the top of the flats is 0.776". The smaller end is 0.67" at the base and 0.753". It was made by Moore Drop Forging Co out of Springfield, MA.

The Rolls Royce is stamped "BSF" which stands for "British Standard Fine" which means it was a fine threaded bolt (really, the thread pitch needs to be part of the size?). It's similar/related to Whitworth in that the sizes are for the bolt sizes, not the head sizes. I don't know if the normal/coarse threaded Whitworth stuff had different sized heads that the fine threaded stuff or not. The edges and corners where it's machined are nice and sharp. It's got the feel of a quality tool.

Then, because I'm an OLD tool nerd and a math nerd, I bought a boxwood and brass rule that has an integrated Coggeshall slide rule which was designed to calculate the volume of timber.

This rule was made by John Rabone & Sons. This model (2423) of rule is in their 1878 catalog that is available online which lists the cost as $30/dozen. I'm sure they made this model for many years, but they'd stopped by the 1930s because there's another catalog available that doesn't include any with the fancy joints. By then they'd switched to just "round", "square", and "arched" like Stanley, etc.... I suspect they didn't continue making the "vulcan joint" (curvy brass hinge) for long due to cost and ease of manufacture. The slide is stamped on both sides. The back is stamped so it could be extended and used to measure something longer than a foot, but that you couldn't fit the rule into unfolded. I think the "J19J" stamp on the back of the slide and inside the slide groove on the body is either to tie this particular slide to this particular body back when they were hand made and fitted or if they were made by machine, maybe just to make sure that the correct model of slide was put into the correct model of body if they were machine made.

And then another couple of items that I bought are some 9/32" drive tools. Yes, 9/32" drive, not just loose 1/4" drive. A bunch of tool manufacturers made 9/32" square drive tools. I found the following on a website about the Snap-On version.

"The Midget drive is a mystery to most people. This size of the square is 9/32 and looks like looks like the modern day ¼ inch drive but is not interchangeable. Plomb also made a 9/32 inch drive set as others did.

Snap on started the 9/32 in the early 1920, and was dropped from the mechanics catalogs by 1945. The industrial catalogs continued the “P series” through the 1960s. These are the same tools relabeled with a P, so an M-5 is pre 1945 and a PM-5 is post 1945."

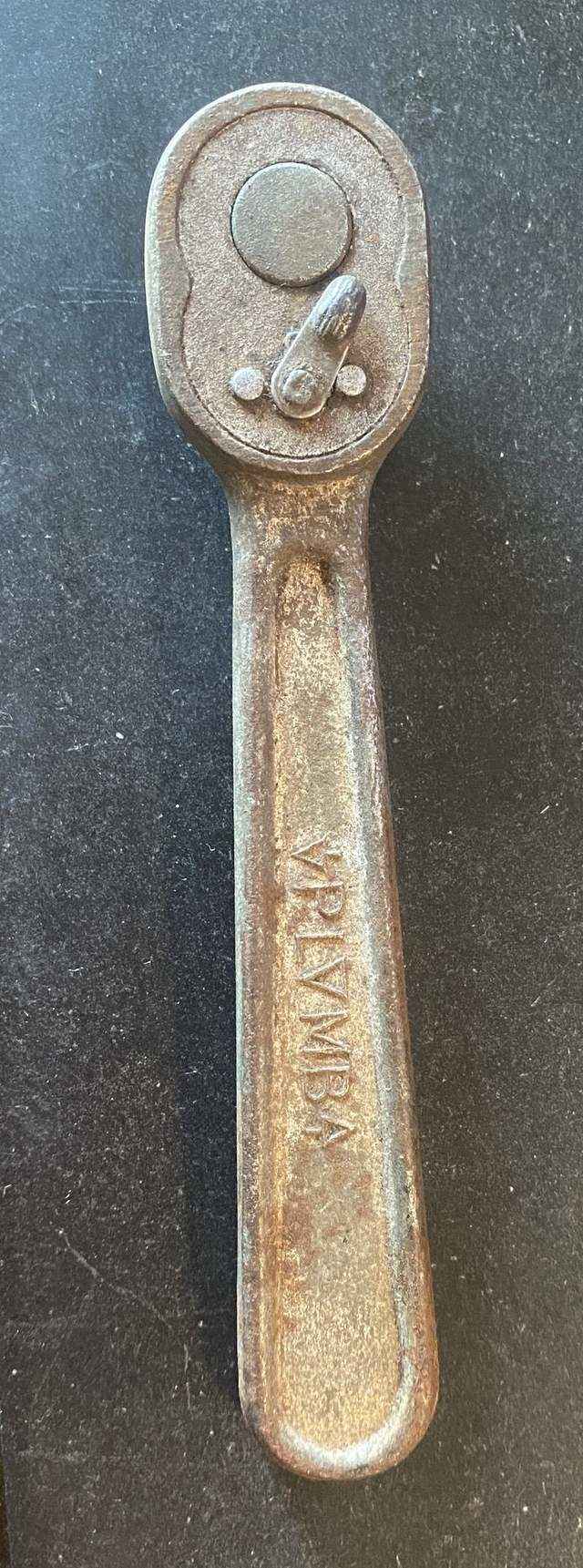

I got a PL∇MB ratchet for $5. So then I had to pick up a cheap, partial Snap-On kit to have some stuff to go with the ratchet. There are some pretty complete kits available in the $130-250 range. I don't want or need these that badly, LOL. I may pick up a couple more 9/32" items so these are more functional. I've seen a 9/32" to 1/4" adapter and a short extension, and several more sockets available.