|

|

|

|

|

|

|

|

|

|

|

Registered User

|

Yes, manufacture date 19 Sept 2008.

With a real porsche number printed on the outside edge under the glyco logo: 930 147 01

__________________

Hugo |

||

|

|

|

|

Registered

Join Date: Aug 2013

Posts: 203

|

Is it possible Glyco are not aware of these issues?

Pelican obviously deals direct or with a distributor, perhaps that would be an avenue to improve the quality of the product? |

||

|

|

|

|

Registered User

|

I was about to send back the rod bearings to Pelican yesterday. I thought it was a good idea to measure all of them just in case somebody call me back on the reasons of the return. After doing so, what I’ve say in post #16 ‘’The Glyco measurement were all over the place’’ is not entirely correct, and I would like to bring a precision;

The center part of the bearing all measure 0.0585’’ but the tapered end (measured 1/8’’ from the edge) are much less accurate, ranging from 0.0575’’ to 0.0585’’. I then noticed that all of the bearing that we tried were showing a small mark on the edge near the notch (circle in red on the picture). I have measure the thickness of the bearing at this location, and I got results from 0.0605’’ to 0.0625’’. This is huge compare to the rest of the bearing. I’m convinced that this small but high spot is the cause of the marks on the flat ends (blue circles) since it’s pushing the shaft on this side of the rod, and that is causing the rod to seize. The original Porsche bearing does not have this high spot. I have to conclude that this is a manufacture defect on this lot. I would also stay away from other lots run at the same South African plant.

__________________

Hugo |

||

|

|

|

|

Project Addicted

Join Date: Jul 2012

Location: Eastern Shore. MD

Posts: 919

|

To give another data point, my daughter (with my guidance) is building a 3.4 and we are changing the rod bearings and bolts. She is home this weekend, so we grabbed the bearings and measured them the same way as Onevoice in the first post.

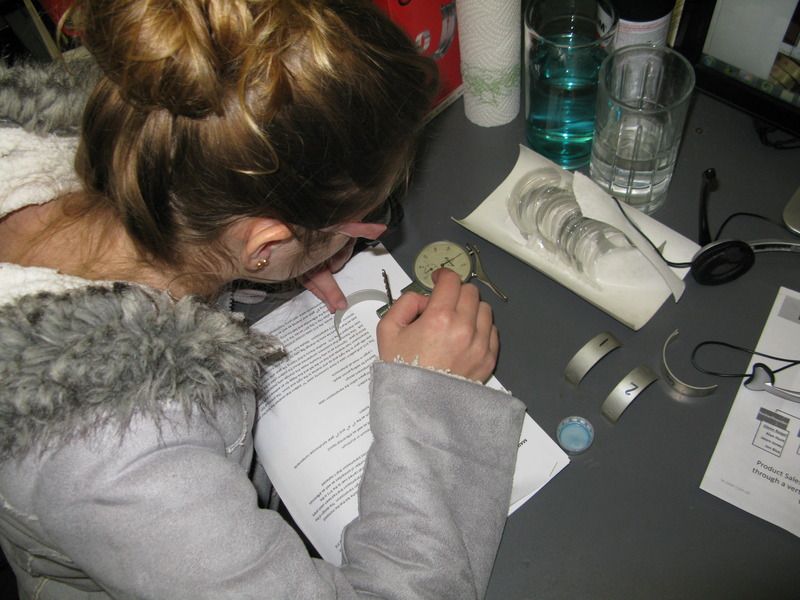

We used a calibrated snap gauge and a drill to do the measurements and they came out excellent. The bearings were manufactured 07-09 in Germany. I have read here that these are the only reliable bearings and that any from the other countries do not measure up. I found these online for $25 from someone's "new old stock" and took a risk that they would be good. We have only random sampled them so far but here are the details of the 4 measured so far. The same way it was done before and in the same places. All measurements are in inches and they are very consistent.  Bearing package, exactly the same as others have.  Country made in is a sticker on the outside of the box  Cal sticker. It's old but the tool is rarely used. Mostly for Ducati valve adjustments.  Mitu snap gauge; calibrated  How we measured on the edges, I used a drill but a ball bearing might have been even easier.  Allie concentrating to get the drill rod vertical and the bearing rocked to the lowest reading  It gets easier with repetition. and she was able to get very solid measurements.  Tomorrow she begins the major portion of the build. Rods, pistons and heads. We hope cam towers. I will take pictures and post in another thread.

__________________

Jon 1966 912 1976 911 3.4 Backdate Project 1986 944 |

||

|

|

|

|

83 911 Production Cab #10

|

Quote:

__________________

Who Will Live... Will See    83 911 Production Cab #10, Slightly Modified: Unslanted, 3.2, PMO EFI, TECgt, CE 911 CAM Sync / Pulley / Wires, SSI, Dansk Sport 2/2, 17" Euromeister, CKO GT3 Seats, Going SOK Super Charger Last edited by JJ 911SC; 03-27-2015 at 03:39 PM.. |

||

|

|

|

|

Project Addicted

Join Date: Jul 2012

Location: Eastern Shore. MD

Posts: 919

|

Yup, I will be watching and prepping parts for her to install. I have built enough engines (1st 911 tho) and Allie is just at the beginning of her mechanical career. She welds tig, mig and gas already, and has done a valve job on her 944. Now into the real good stuff. We can OCD with measuring tools and torque wrenches.

__________________

Jon 1966 912 1976 911 3.4 Backdate Project 1986 944 |

||

|

|

|

|

|

Registered

Join Date: Apr 2005

Location: AZ

Posts: 251

|

I am joining the ranks. Glyco rod bearings, part number 930-103-147-15, Made in S.

Africa, 713427, 02-16. Exact same problem. I took the crank, rods and bearings t my local machine shop and the bearings pinch at the splits. In the picture the pointer is left of zero, that means negative clearance. Last edited by rs-vic; 01-03-2017 at 01:45 PM.. Reason: typo |

||

|

|

|

|

Registered User

Join Date: Jan 2011

Posts: 17

|

Glyco vs clevite rod bearings - with data

I have noticed that ARP head studs should be installed the other way around. Dome end of the stud should be on to the engine case side.

|

||

|

|

|

|

Registered User

Join Date: Jan 2011

Posts: 17

|

|||

|

|

|

|

Registered

Join Date: May 2004

Location: Boulder, Colorado

Posts: 7,275

|

What do you mean? One nice feature of the ARPs is that dome, and it faces "up", which is to say it is where the head nuts go. Because of the dome the washers drop right in, and so do the nuts. No fiddling around.

Alas, Henry's nice Supertecs don't have this feature, and ARP doesn't have the fine thread for the nuts. Couldn't put Supertechs in backward if you tried, though that wasn't the reason for the finer thread. |

||

|

|

|

|

Registered User

Join Date: Dec 2014

Posts: 168

|

Quote:

Those bearings were dated almost 2 years after the ones I measured in the first post of this thread. There is NO WAY I would ever use anything that came out of that S. African glyco plant. Buy the Clevites. |

||

|

|

|

|

Registered

Join Date: Apr 2005

Location: AZ

Posts: 251

|

Are the Clevites still available?

|

||

|

|

|

|

|

Registered

|

We got ours from Henry at SuperTec - - but I think EBS has them too and are a retail supplier.

Regards,

__________________

2002 Porsche Boxster S Cobalt Blue/Blk/Blk Crew Chief for Son's 1978 Porsche 911SC Original Porsche Mocha Brown 3.8L NASA race car Previous Porsches: 1958 356 Red Coupe - 1972 914 Blue -1972 911T Coupe Aubergine |

||

|

|

|

|

Registered

Join Date: Jan 2006

Posts: 174

|

Yes exactly. I don't know these studs so I do not know what threads are at each end. Normally head studs have a domed end so that when and if they ever bottom out when tightened the stud does not distort the block or in this case, the engine case. It is done for a purpose. Not to make the washers and nuts go on easier.

|

||

|

|

|

|

Registered

Join Date: May 2004

Location: Boulder, Colorado

Posts: 7,275

|

Well, something new comes up all the time. Porsche's studs have the same flat end on each end, as well as the same thread, so there is no endedness to them. The ARP studs have the same thread on each end, so they could be put in either way as far as that is concerned. Henry's studs have no domes. The ARPs have quite a bit more thread on the non-domed end than on the domed end, and it makes sense that you would benefit from more thread engagement in an aluminum or mag case than on the head nuts, which are engaged full thickness anyway. And one reads instructions which say things like don't bottom studs - use a locking compound if worried they may be unscrewed when it comes time to remove the nut. So I'm not quite buying this. Maybe someone could talk with an ARP engineer to see why they put that dome on there, and which end is supposed to be which. I have ARPs in one engine, but someone else built it originally, and I just rebuilt it to freshen up the bearings so didn't remove the studs. The builder was an engineer - an ME, I think, but worked for an airplane manufacturer.

|

||

|

|

|

|

Registered User

Join Date: Jan 2011

Posts: 17

|

Quote:

I'm in the process of engine rebuilding when I saw the photo posted re ARP head studs. I though I have installed it wrong and second doubted myself. I called ARP tech support and confirmed that the dome end should be on the engine casing side.

|

||

|

|

|

|

Registered

Join Date: Feb 2007

Location: Northeast

Posts: 464

|

Fatboy, Why don't you start a thread on your rebuild? I'm sure many would like to see.

__________________

Mark www.exotechpower.com 1981 Targa-messed with. 91 C2 supercharged track rat Radical Prosport-irritates the GT3 guys 40 years of rebuilding services |

||

|

|

|

|

Schleprock

Join Date: Sep 2000

Location: Frankfort IL USA

Posts: 16,640

|

Thanks to rs-vic for adding another data point on faulty bearings. I've got a set of Glyco 3.0 SC rod bearings on the shelf from S. Africa, purchased from Pelican, that i'll measure when I get a set of rods. But i'm pretty sure those will be placed in the "circular file" too.

You can get the Clevite AA bearings here at Pelican. Pelican identifies them as part number 930-103-147-15-M987. M987 is the supplier designation for Automobile Associates. 1986 Porsche 911 Carrera Coupe - Main Engine Components - Page 4 The ARP instructions are usually pretty good and i'm surprised they don't make any mention of the domed/unthreaded tip side of the stud being inserted into the case.

__________________

Kevin L '86 Carrera "Larry" |

||

|

|

|

|

Registered

Join Date: Jan 2006

Posts: 174

|

""""The ARP instructions are usually pretty good and i'm surprised they don't make any mention of the domed/unthreaded tip side of the stud being inserted into the case.""""

A good point. I'm not surprised that this was unknown in the DIY world as many so called Pro builders are obviously unaware of this by virtue of the direction they install the studs or they don't have this feature added to their aftermarket studs. In the "case" of these Porsche engines, installing all 24 head studs the wrong way around and bottoming them, a common mistake, the main housing bore will distort and the oil clearances change to the main bearings. Now torque the heads with the studs backwards and the studs bottomed out and you make this problem even worse. Installing head studs should not be considered a simple procedure, but a very important and complex assembly as they have a huge effect on other parts. |

||

|

|

|

|

Try not, Do or Do not

|

We carry most sizes in stock standard and undersized. .25 mm.

__________________

Henry Schmidt SUPERTEC PERFORMANCE Ph: 760-728-3062 Email: supertec1@earthlink.net |

||

|

|

|