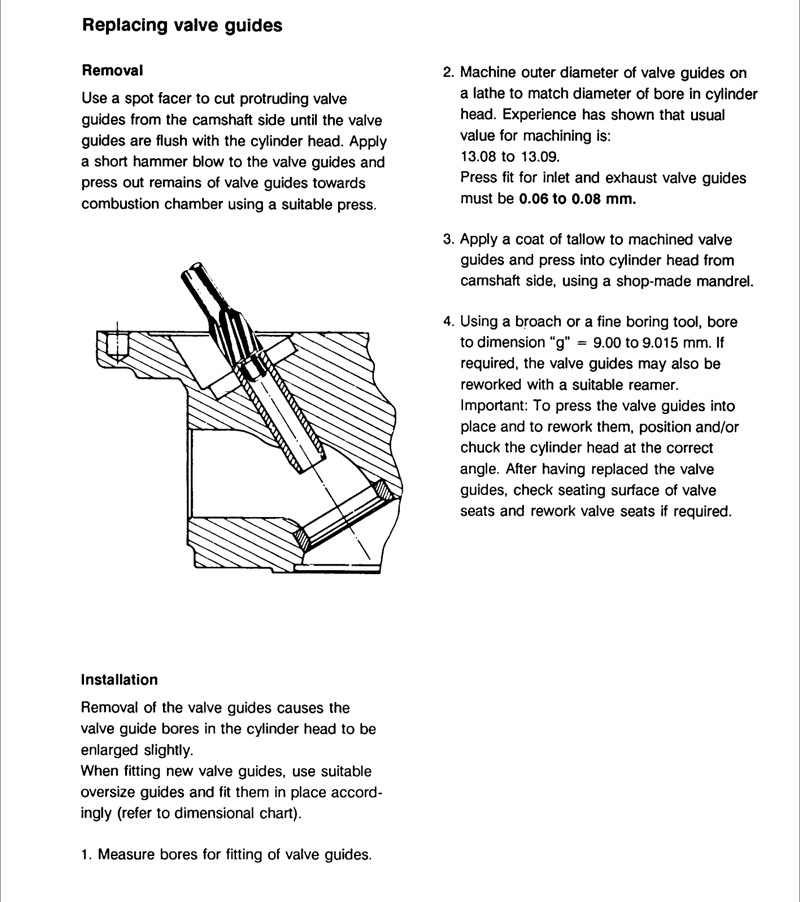

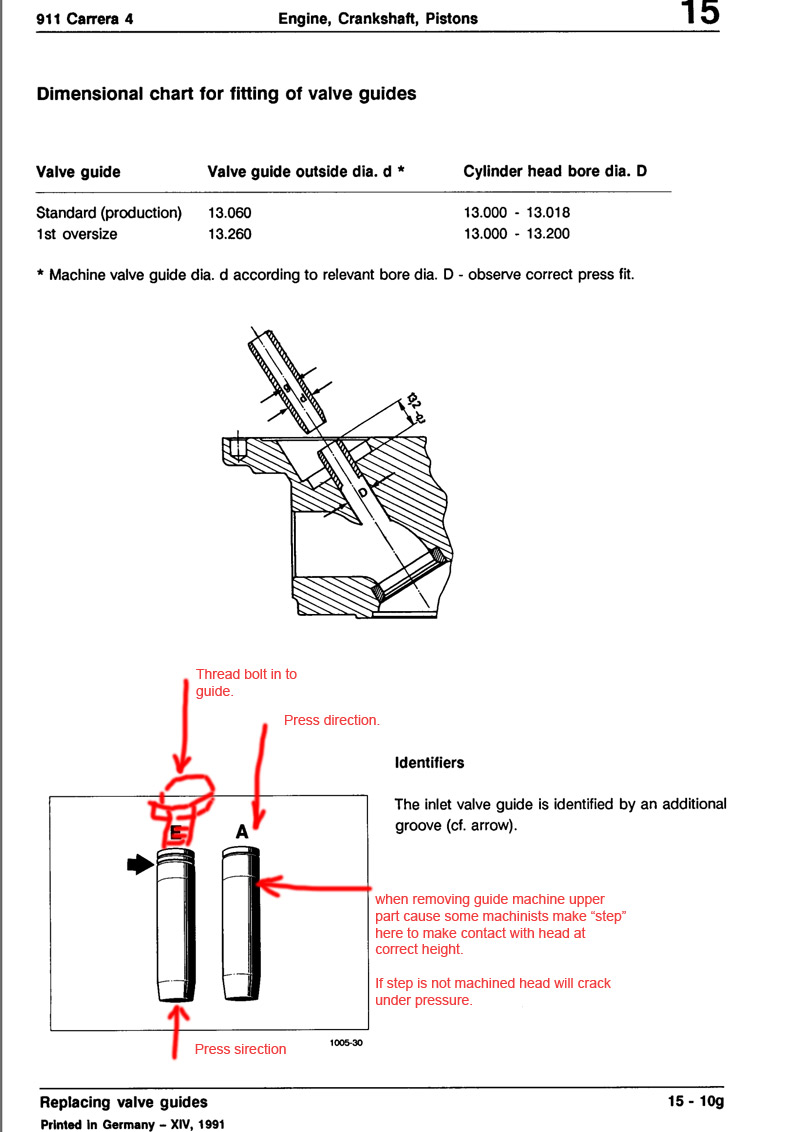

Here's factory recommended way - you need to machine down bronze till you see aluminum head.

Some machine shops machine step at valve guide top, so it will stop at correct distance. Problem with that - step will crack head and it's very hard to notice cause it's against head.

I used bolt as stop and press guide from chamber, it's not uncommon practice.

PS. As noted above most of pics in this thread will disappear sometime during Mar 2017

I have backup with pics here:

964 Oil leaks & fixes thread. with images