Quote:

Originally Posted by rfuerst911sc

So yes your diagram is basically how the building and the compressor room will be built . The studs will be 2x6 with plywood on the exterior and house wrap and OSB on the interior . Standard fiberglass insulation is the plan . Probably vinyl siding on the exterior for minimal maintenance . I will insulate the back of the compressor room door for noise suppression and even thinking about leaving a open space on top of the three perimeter compressor room walls of maybe 3 - 4 " and cover with window screen/hardware cloth of maybe 1/8 " or 1/4 " grid . My thoughts are two fold: one it will allow some noise to escape and two that will allow intake/cooling air for the compressor pump . Have any of you guys done something like this ? I would size the roof over the compressor room to allow coverage so wind driven rain would not come in .

|

I tihnk you're maybe missing some of the details.

Quote:

Originally Posted by Bob Kontak

Interesting on the double layer of drywall.

Does code require the 5/8's drywall for a detached building? Would be cool to have two layers up to 1 1/4", but why? Not a push back. Just asking.

R3 per half inch sheet or thereabouts. Say R4 for fire sheetrock.

|

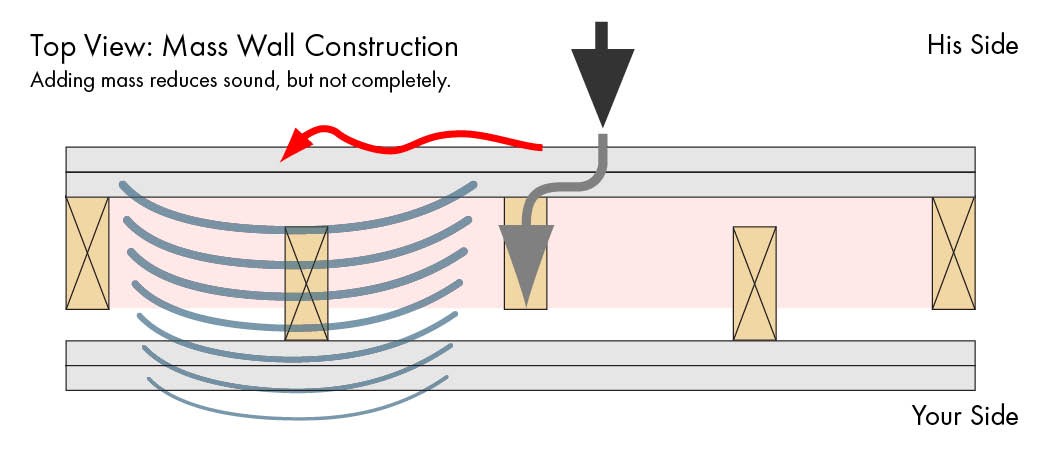

I don't know anything about the details. It was just the results of a google image search for a technique of sound damping interior walls. Maybe this will demonstrate better for RF.

The point is that the header and footer of the wall are 2x6, but the upright studs are only 4" and alternate which side of the wall they attach to. That way the sound can't vibrate from drywall to stud to drywall because there is a 100% air gap alternating through the studs the length of the wall.

I assume the 5/8" is just to make the wall extra thick and heavy for more sound deadening.

__________________

Steve

'08 Boxster RS60 Spyder #0099/1960

- never named a car before, but this is Charlotte.

'88 targa

SOLD 2004 - gone but not forgotten