|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Jul 2008

Location: Baltimore, MD

Posts: 153

|

How do they shuffle pin cases?

I am just wondering about the accuracy of the machining when they shuffle pin a case? How is this even done? Two separate cases that are supposed to accurately mate? How is this done? Anyone seem a machinist do it? Does the case have to be completely remachined when they do this mod? I am having a hard time figuring out how the holes will be lined up after wards.

I know i am not a machinist and am thinking too much. Please indulge me...

__________________

2000 VW TDI 224HP/400FT TQ. Pikes Peak World Record Holder 2007 "Fastest Diesel Car" 1973 Porsche 914/6 2.4L Engine rebuild in progress |

||

|

|

|

|

Registered

|

A machinist works with highly accurate equipment and if competent they can control spatial relationships , depth, bore, trajectory within thousanths of an inch. Experiance makes doing shuffle pinning a relatively simple task.

Obviously checking the case fit before cleaning is prudent. Without the crank or anything else it should knock together and apart evenly and without hangups. I only had two pins placed in the center web of my Mag case. Not a race engine. I lightly tourqued down a few perimeter bolts and through bolts with the case dry with bearings in place. A final test - and it pushed the bearings to where they needed to go without the IS and crank's interference. Then I lubed and placed the crank, seals, pump/IS, nut&tabs, seals etc and prepared my hardware. Used the Locktite, left side. Dropped the case over and got ALL the hardware connected (without green O-rings, yet) - the case halfs hadn't touched yet. When all was in place I knocked them together and started progressivly tightening. I went back after a couple of hours and placed the O-rings, running them over a Sharpie cap with the clip removed and sanded smooth. The last paragraph was not intended to redirect the direction of this thread - I had wanted to share my observation that you can get the hardware all in place before the cases drop together and the locktite starts to cure. Seemed like a decent place to mention it. Perhaps the pins helped hold the case halfs apart for that brief and helpful time.

__________________

75 911S Targa - Mine from 2001 until sold to Germany buyer 10/2016 <ALL DIY> Brakes/Wheels '01, Body/paint/restoration 7/04, Suspension 3/07 Engine rebuild - done 7/08 - added 28 tube cooler and SSIs - running strong. Ducktail painted. 2021 MachE, 2012 Outback, 2019 Crosstrek, 2018 Impreza wagon Last edited by notmytarga; 07-25-2008 at 09:51 PM.. |

||

|

|

|

|

Registered

Join Date: Jul 2008

Location: Baltimore, MD

Posts: 153

|

Yeah I understand all that, but it just seems so amazing to have such a tight fit and was just amazed at the precision. I would really love to see it done. See how they measure it all out to drill the holes and stuff. Really cool. Overkill for me I think, but will have it done anyway when the case gets checked and machined for straightness.

__________________

2000 VW TDI 224HP/400FT TQ. Pikes Peak World Record Holder 2007 "Fastest Diesel Car" 1973 Porsche 914/6 2.4L Engine rebuild in progress |

||

|

|

|

|

abit off center

|

Here is how we installed the alignment sleeves in our Mag case: I first made a jig using an old case, The jig case was aligned and the thru bolts reamed to 1/2" We then used the jig to ream the mains in the good case to accept the stainless alignment sleeves, they are 1/2" deep into the case, Then we used the other half jig to ream the thru main bolts on the other half of the case, also 1/2" deep. This still gives plenty of oiling thru the passages, but you must also notch or drill oiling holes in 3 of the sleeves for the piston oilers on one side of the case. This case needed to be bored anyhow so this was also done after the sleeves were installed but it did come out spot on, a lite tap with a mallet and it pops apart.

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

Registered

Join Date: Jul 2008

Location: Baltimore, MD

Posts: 153

|

I thought that they are normally smaller pins and separate from the thought bolts? Never seen that way of doing it?

Interesting. That seems a lot more weak to me than solid smaller pins?

__________________

2000 VW TDI 224HP/400FT TQ. Pikes Peak World Record Holder 2007 "Fastest Diesel Car" 1973 Porsche 914/6 2.4L Engine rebuild in progress |

||

|

|

|

|

abit off center

|

Its actually the same way they align the rear main on the case except we carry it thru all the mains.

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

|

Registered

Join Date: May 2004

Location: Boulder, Colorado

Posts: 7,275

|

The most common shuffle pins get put in like this, I think:

Put a case half on the machine that will do the drilling (or whatever you are doing) and set up just right. Drill holes in the webs, one on each side of a main bearing. Insert transfer punches into the holes. Clamp the case halves together. Now you have punch marks on the undrilled case half that line up with the holes just drilled. Put that case half on the machine, use the marks to center what does the drilling, and drill those holes. Insert dowel pins, and you are there. I have a case pinned in this way (by a skilled machinist with the right stuff, to be sure, not by me with a drill press or hand drill), and it seems to work. Not a pain to separate the case halves, anyway. Which I take to be a sign that the "register" of the holes was very good, and nothing is getting distorted as the pins force their way into their opposite holes. A machinist who did work for me didn't like this method, though. He said it was just too hard to get the register perfect (not sure what that was for him, a ten thou?). He preferred sleeves as shown in Cgarr's photo. VWs had these, I seem to recall, and of course Porsche did it with the #1. He had a system whereby he could get these sleeves lined up "perfectly", by which I think he meant by drilling through both halves while they were clamped together. Not sure how he did this, since you don't want to widen the throughbolt holes except where the sleeves go. Perhaps he widened the holes on one side, then inserted a bit of some sort with a narrower shank than the working end so its smooth end stuck out the outside of the case. Then he could clamp things together, put power to the drilling implement, and have it drill into the other side. He made the sleeves on his lathe. One detail is the need to shoulder each of the new holes, lest a sleeve work its way in deeper and block an oil passage. He must have used sleeves which went in less than a half inch, as no notching was needed. Sleeve look to me like a better mousetrap. Not something I can do in my garage. Cgarr - are 1/2" x 1" stainless sleeves something you can just purchase already made? By making things a little shorter could you avoid the notching? Will your jig work on any engine, or is there enough variation that it is specific to the case you sleeved with it? Walt Fricke |

||

|

|

|

|

abit off center

|

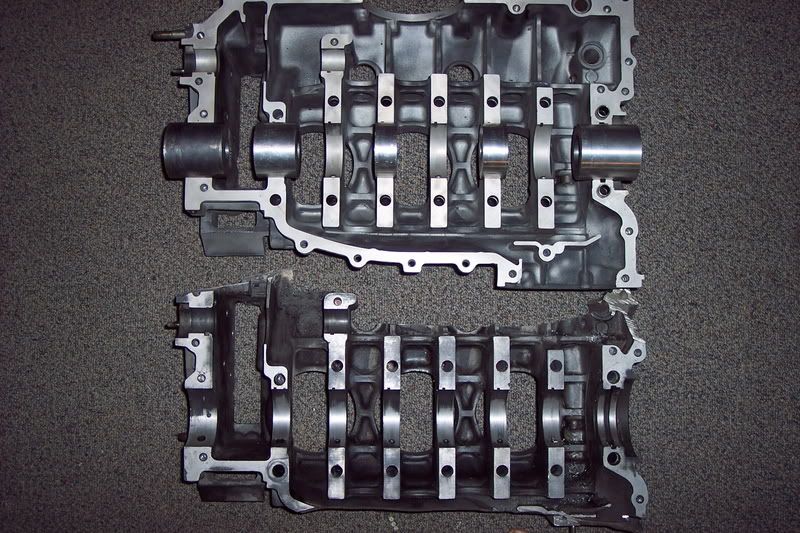

Walt, The jig I made will work on any 2.7 case or a case with the same size mains, The jig is lined up using the mains, I made alum guides (as in photo) similar to the #8 nose bearing to hold the case square with the mains while reaming out the sleeves. I was actually surprised when the case just "snapped" together without any binding. The sleeves were made out of SS seamless tubing which pressed into one half of the case but before I did that I took off about a half a thou on the other half of the tubing because I did not want a tite press fit when putting the case halves together.

The tubing was purchased by the foot, I just cut off the length I need so you could really make them any length you wanted, as you said, shorter may have been better, it was really a pain to get those squirter holes drilled and lined up just right and you really would only need an very small amount of sleeve to hold the mains once its all bolted up anyhow.

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. Last edited by cgarr; 07-27-2008 at 05:30 PM.. |

||

|

|

|