|

|

|

|

|

|

|

|

|

|

|

RonH

|

I have just completed rebuilding my 3.2 Carrera and streching it to 3.4 l with 98 mm 11.5 JE pistons and reboring and plating of the original cylinders. The conrods were balanced. Have added twinspark. I have reassembled it 3 times now. The engine runs very well and appears to be much more powerful. BUT after each of assembly the cylinder/head interface have started to leak. Have added the following:

Height matced (Again) cylinders and heads Added bottom spscer gasket to get deck height to 1.3-1.4 mm (CR +-11.2) Have matched cylinder/head interface Have replaced bottom dilavar studs with steel Leaks occur only at bottom of cylinders. No sign of detonation. all else inside engine looks great. Pressure testing during assembly seems fine. Pressure leaks seem to start by second or third heat cycle i.e. +- 50 to 100 miles. Oil leaks at bottom of cylinder. Seems to be 964 ailment. I am out of ideas and patience. HELP! |

||

|

|

|

|

Registered

Join Date: Apr 2006

Location: northeast

Posts: 4,532

|

so the leak(s) is at the base of the cylinders where they plug into the case, right? How many cylinders are leaking??

__________________

I live for 911 tweaks... |

||

|

|

|

|

RonH

|

No, both upperr and lower. As if the cylinders shrink. After last assembly 3. Have torqued 33 Nm, 39 Nm and 20 Nm + 90 degrees.

|

||

|

|

|

|

Registered User

|

If I'm reading your post right, the leak is a pressure leak or compression leak between cylinder and head. You have tried 3 times to get the seating surface of the cylinders to heads better. Sounds like you might have a miss match of studs. After the heads and cylinders get up to temp the pressure leaks start. If the top studs are expanding, stretching, faster than the bottom studs, or visa-versa, you will have a compression leak. Assuming you had the machine work done correctly. What stud set are you using? With that much compression I would be using 993TT studs.

__________________

Mark Jung Bend, OR MFI Werks.com Last edited by 356RS; 02-15-2009 at 11:16 AM.. Reason: 993TT instead of 933TT Got my # off |

||

|

|

|

|

RonH

|

My original assuption as well. I replaced the bottom Dilavar studs, standard one side and 993 (same) other side with standard steel studs. Theoretically it should now be in balance. But it hasn't made a difference.....

|

||

|

|

|

|

Registered

|

When you changed the studs, did you measure the height of the studs off the block to make sure they were corredt? According to Wayne's book, the stud height should be 135mm. If the studs are not threaded in enough that might contribute to your leaks.

|

||

|

|

|

|

|

Registered

Join Date: Apr 2006

Location: northeast

Posts: 4,532

|

all cylinders from the same height group? Since you measured these 3x probably a mute point but just wanted to say.

I would agree with Mark that since you are running 11.2+ compression ratio & probably generaring a bunch of heat i.e. thermal expansion, something is out of spec for level/parrallel or binding somewhere? Bob

__________________

I live for 911 tweaks... |

||

|

|

|

|

RonH

|

All cylinders were height matched when plated. All studs were threaded in to match originals i.e. 135 mm.....

All I can think of now is that the cylinder base gaskets (1 mm) are deforming too much in a heat cycle or oil gets in the joint when the engine cools....? |

||

|

|

|

|

Registered

Join Date: Jul 2001

Location: Portland Oregon

Posts: 7,007

|

JMHO,...I've not had much success using steel studs in these large-bore engines, especially at those CR's.

Steel ones simply do not expand & contract at the same rate as all the other non-ferrous parts and that results in uneven clamp loads on the heads and cylinders. We see the evidence at the tops of the cylinders and head sealing surfaces. Naturally, we do not stack base gaskets, either. I've had the best luck using 993TT head studs (Dilavar) with engines such as yours. While not cheap anymore, they really prove their mettle in this circumstances.

__________________

Steve Weiner Rennsport Systems Portland Oregon (503) 244-0990 porsche@rennsportsystems.com www.rennsportsystems.com |

||

|

|

|

|

1984-911 M491

|

This subject had me a little worried. With an engine rebuild on my mind, I’m wondering if this leakage is abnormal for a 1984-3.2ltr with 40,000 miles?

5 of the 6 cylinders look similar. The #2 cylinder is completely dry.

__________________

1984-911 TLC......SOLD |

||

|

|

|

|

RonH

|

Thanks Steve. Does this often occur? Especially with 964 and 993 engines - distortion in the heads? I see Porsche went to steel with the 964 and back to Dilavar with the 993? Incidentally, had a very simple splitter amplifier made made to drive the twin spark from a standard DME. About $50

Trog, thats what it looks like Ron |

||

|

|

|

|

Registered

Join Date: Jul 2001

Location: Portland Oregon

Posts: 7,007

|

Hi Ron,

964 & 993 engines used cylinder base O-rings, not gaskets like previous engines and its not difficult to experience a problem at the base from damaged O-rings, improper installation or physical damage to cylinders and/or case spigots. Regarding the head to cylinder junction; these can leak for various reasons such as: 1) Head sealing surfaces damaged or not flat & square. 2) Sealing ring issues. 3) Uneven head stud clamping pressures. Its important to remember that the 3.6 engines ('90-'98) have a greater span between the top & bottom rows of studs which creates bending loads with high CR's and temperatures. The potential for leakage along the surfaces between heads is why we weld the heads. This additional material adds stiffness along that plane and helps maintain the integrity of the head sealing rings. This is why its so critical to maintain even head clamping pressures in ALL of the big bore (3.0 and larger) from cold to extreme operating temperatures and the late 993 TT Dilavars are the best choice, hands down. JMHO, of course,....

__________________

Steve Weiner Rennsport Systems Portland Oregon (503) 244-0990 porsche@rennsportsystems.com www.rennsportsystems.com |

||

|

|

|

|

idc1873

|

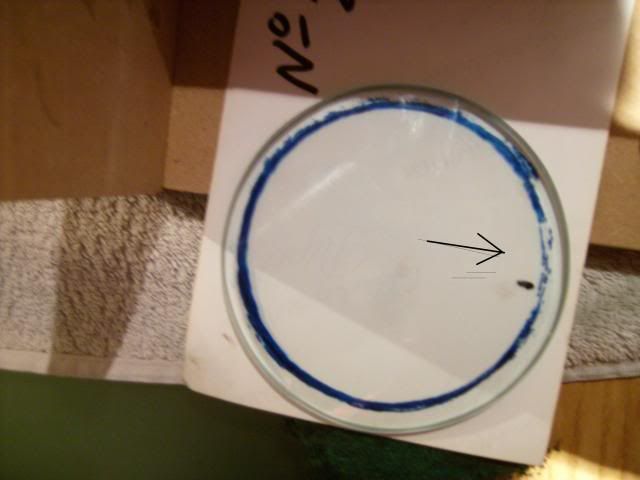

I had the same problem on my 1987 3.2. Rebuilding it at the moment.

http://www.impactbumpers.com/forum/index.php?showtopic=7870 On No2 & No6  Glass plate with engineers blue shows the leak.  Made a jig to lap the heads in.

Last edited by coxy; 02-16-2009 at 12:33 AM.. |

||

|

|

|

|

RonH

|

I think I have discovered the answer. The top mating surface of the cylinder must be wedged. The inside should be about 0.07 mm higher than the outside so that when the engine warms up it still seals on the inside or over the whole width. If the surface is flat the joint will tend to open up on the inside as the engine warms as the head deforms. Combustion debris will ten to remain there and the next time it will open up more. Probably more pronouced with high compression motors. My old cylinders that never leaked are made that way. So coxy I would leave them as they are or get the wedge right.

Comments? Ron |

||

|

|

|

|

idc1873

|

Quote:

The gap on the exhaust side where mine was leaking from was only measurable by using the engineers blue. They only took a minimum of lapping in and still had a taper to the top of the barrels afterwards. So in that respect i should be OK. I have searched several forums and spoke to several people regarding this, your post is the first i have found on the subject, indicating it isn't a very common problem. Haven't found any explanation as yet. Last edited by coxy; 02-17-2009 at 04:32 AM.. |

||

|

|

|

|

idc1873

|

Not wanting to upset you Trog, but thats what mine looked like at 65k

|

||

|

|

|

|

abit off center

|

These heads will get a wash boarding of the sealing surfaces, I have never found a used set that was perfect yet! The least amount I have ever taken off to clean a set up was .003 but that was to match and bring all 6 heads to the exact height too:

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

1984-911 M491

|

The previous owner of my car failed to perform valve adjustments as recommended. When I took care of the valves, I re-torqued the heads. I'll wash the engine down and keep on eye out for further seepage. With hope, tightening of the heads sealed her back up.

__________________

1984-911 TLC......SOLD |

||

|

|

|

|

|

Manassas, VA

|

Ron,

Would you be willing to share the details on your signal splitter? Drawing, schematic, parts list? Thanks, Mark

__________________

1991 964 Polar Silver Metallic Turbo Coupe |

||

|

|

|

|

RonH

|

I have found reference to the wedged top cylinder surface in Bruce Anderson's book Pages 86 and 95. Some racing engines also used this arrangement. The sealing ring in other engines is for when the surface is flat.

No problem sharing the information on the splitter. It was built for me by Distributor Remanufacturers in South Africa for about $60. Must open the box and see whats inside. Send e-mail to awharmse@telkomsa.net and I will see what I can do. |

||

|

|

|