|

|

|

|

|

|

|

|

|

|

|

Registered

|

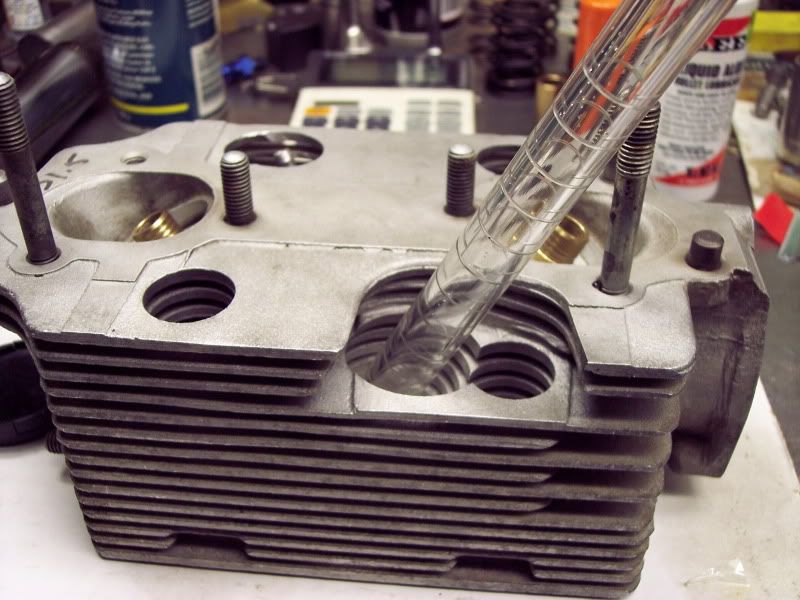

Step by step procedure on how to cc your head volume

searching for CC or head volume or compression ratio returns a wealth of knowledge, but not exactly what I wanted which was a step by step on how to measure the remaining volume.

so here's my step by step procedure on how to cc your head volume so others can chime in in case I screwed it up. This assumes your engine is out and on the engine stand for rebuild. 1) TDC with Z1 mark aligned to case parting line  2) spark plug removed 3)both valves closed. Which is easy to ensure when the cams are not installed  3) Tilt the engine about 30 degrees so that the spark plug hole is as close to vertical as possible  I'm showing the CC check for cylinder #4, but I did #1 and #4 both with nearly identical results when I figured out what not to do. 4)Get something that can easily measure small volumes of liquid. I used a 10mL syringe.  5)Pump liquid into the spark plug hole until you are close to what you already expect. I used rubbing alcohol because it's what I've been cleaning the parts with anyway. I expected 62CC of volume, but people say the JE pistons yield higher CR ratios (and therefore less volume at TDC) so I stopped at 50CC, and started checking more closely at 1CC increments.  6) I measured how far down the threads of a spark plug normally sits in the hole. I approximated that the volume of the electrode plus ground tab extending down into the cylinder was just equal to the air gap left inside the body of plug (Ok, really I said close enough, and ignored everything that was not the main body of the plug.) This distance came out to be 11.5mm  7)I then locked my calipers in at 11.5mm and now had a dipstick!  8)At every single CC increment above 50cc, I stopped to check if the dipstick was touching the rubbing alcohol in the cylinder. You can see the surface of the liquid distort in shape when the end of the dipstick touches. You would think that it would be obvious and apparent when the liquid in the cylinder reaches the bottom of the spark plug threads, and that you could stop there. But no, with the clear liquid, and a trick of reflection off the crown of my piston, I actually looked straight through the alcohol and kept adding more. I knew something was amiss, and devised the dipstick, and was shocked when the dipstick immediately touched the liquid at only one mm from the TOP of the plug threads.  9) which brings me to why a syringe is the right tool. I then added a small hose to the end of the syringe, and sucked the liquid out of the overfull spark plug hole, being sure the hose was positioned squarely at the bottom of the threads, I kept drawing until I was drawing only air into the syringe, then measured how much came out, and did the simple math. 10) repeat enough times to be sure of your results. 1cc difference is 0.2 on the CR. Results? Cylinder #1 60.5cc 59cc 59.25cc Cylinder #4 60cc 59.5cc 59.25cc Taking the lowest, this makes my CR 9.95:1 instead of 9.5:1 as JE advertised. (Highest gives me 9.7:1) Of course they say 9.5:1 at .040" (1mm) deck height. I have 1.25mm minimum, which should have made my CR lower than the 9.5:1. Glad I checked. I'll keep the "10:1" CR and be sure to run 93 octane using a Steve Wong chip designed for 91 octane for a margin of detonation protection. |

||

|

|

|

|

abit off center

|

Well,, there is no mathematical errors in doing it that way, thats the way I did it with my 3.2 and 912 engine. Were your head sealing surfaces cleaned up? that could account for the difference but like you said J&E's can be a bit conservative too. Great Job!

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

Registered

|

Mathematical errors?

I'm the king of making bonehead math errors. Which is why I use the engineering mantra "If it's worth doing, it's worth doing three times with different methods to validate the results." anal? maybe a bit.

|

||

|

|

|

|

abit off center

|

I should have said measurement errors, piston dome, combustion chamber etc, all those little bits that change when you torque everything down.. The only error if any would to make sure your right at TDC....

Did you have any problems getting all the air out of the cylinders? I made a clear plastic spark plug tube that I can fill to show outside the cylinder and rotate the crank slightly to find exact TDC and get all the air out.

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. Last edited by cgarr; 01-04-2010 at 07:44 PM.. |

||

|

|

|

|

Registered

|

I worried a lot about left over air in the cylinders. I can't say 100% that I got all the air out, but I can say 99% sure I got all the air out.

1) first clue that there was air trapped in the head: when I had put 55cc in (expecting 62cc) and it was filling up the spark plug hole. So "Burped" it. which is the nice way of saying I grabbed the cases and shook the engine up and down until a bubble came out and the level went down. 2) even then I was getting 59-60cc levels and expected more, so I raised the front of my engine stand (while doing cylinder #1 not pictured) and propped it up 3-4 inches, ensuring the spark plug hole was the highest point in the cylinder. This gained me nothing. I never got even one more minuscule bubble out. 3) I then took a small zip tie, bent it at 90 degrees, and went fishing for bubbles, trying to dislodge any that might have been stuck. I think the ridges on the zip tie introduced all the little bubbles that came out, as net height of the liquid level did not change with the zip tie. All of the above was done with the piston at TDC measured by the Z1 Mark, and fine tuned by watching a small plastic stick's movement up and down while slowly rotating the engine on either side of the Z1 mark, then finding the center of that (Which was damn near perfect on the Z1 mark.) BUT Cgarr's method is probably more accurate. or at least what I think he said is his method. (here, let me put words in your mouth) 1) start with the piston 10 deg before TDC 2)Add expected head volume of rubbing alcohol. Plus add and measure more to get the liquid level touching the bottom of the spark plug hole. 3)Screw in special hollowed out spark plug with graduated CC marking clear tube glued in place. Make ABSOLUTELY SURE when you create this tool that 0.0cc is at the bottom of the plug threads, and each cc above that is marked clearly. (I would envision a thin clear tubing 1 meter long where every 10 cm change in liquid was 1cc of fluid displacement). With the plug tool screwed in, the liquid should be at the bottom of the vinyl tube at the impossible to see 0.0cc line. 4) Hold the tube vertical 5) slowly rotate the engine to TDC and beyond in small increments, marking the highest point the liquid rises to. 6) do the math. Pretend I just did this instead of just making it up in my head, and lets say I measured 65cc of fluid in at 10deg BTDC, then at TDC I had pushed out 5cc of liquid up my clear vinyl tube 65-5=60cc. Then say I rotated it another 3 deg After TDC, and it went up to 5.5cc. well now I learned that my Z1 mark is off by a bit, and that my head volume is actually 65-5.5-59.5cc (or .1 higher on my CR) Of course this is theory only. I wish I had some vinyl tubing here, this is just geeky enough for me to want to do it. Richard |

||

|

|

|

|

abit off center

|

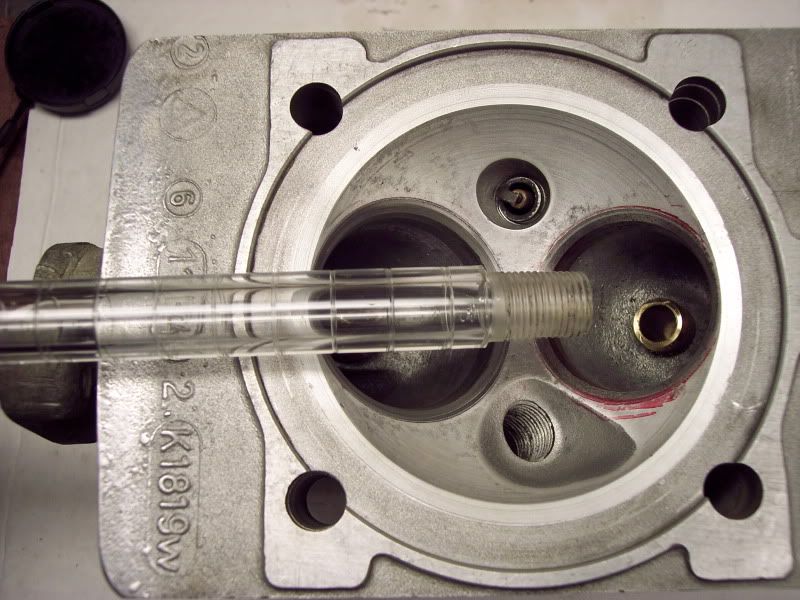

A flex tube will work, I used a rigid acrylic tube that is threaded at one end, the first mark is at 2cc then each mark is 1cc

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

Craig, I think you're on to something there-- insert a threaded tube into the spark plug hole, then pour in a measured amount that is a couple cc more than the "target" volume - note the reading on the graduated tube, then subtract that reading from the known volume you poured in to get the combustion chamber volume. This is the kind of a part that could be mass produced and sold. . . .

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

abit off center

|

You can check my scale, any math wizz's out there, The tube is 3/8 ID but actually measures around .378 each mark is spaced .520 which is 1cc, so how close did I get it? I used my 50cc burette to scale it.

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

Registered

Join Date: Sep 2007

Posts: 500

|

Clever gauge Craig - thanks for sharing

John |

||

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

Craig, if the hard tube is not 100% vertical, can you still get a "meniscus" across the tube that lines up with or between the graduations you marked there? If not, then the tube needs a bend in it that is equal to the amount that the drilling in the head is off-axis to the axis of rotation of the engine on the P201. In other words, you have two axes- one for the drilling and one for the rotation of the engine-- you can turn the engine so the tube points as close to vertical as possible, but the remaining deviation has to come out in the tube.

Easy to verify the thread depth- 14mm, and cut off the tube flush with the cylinder head surface. You would have to subtract some volume for a spark plug insulator and electrode, of course.

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

Registered

Join Date: Apr 2006

Location: northeast

Posts: 4,532

|

a couple of q's:

1. what do you guys use to prevent the (alcohol??) from leaking past your piston ring end gaps or such inside the cylinder?? 2.what liquid do you use...is it rubbing alcohol?? Thanks

__________________

I live for 911 tweaks... |

||

|

|

|

|

abit off center

|

I put a bend in the tube and added an o-ring so you can index it to the same postion each time, were you thinking something like this?

I put some grease on my rings and use fuel oil to measure mine years ago.

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

Registered

|

Quote:

the rings themselves seal up and keep the alcohol in the cylinder. I'm sure eventually it would seep past, or evaporate. Richard |

||

|

|

|

|

Registered

Join Date: Apr 2006

Location: northeast

Posts: 4,532

|

Thx Craig & Richard... you guys answered my questions

__________________

I live for 911 tweaks... |

||

|

|

|

|

Registered

|

Quote:

Not that I think I can "see" a difference of 5% of a cc that's .05" difference in height on your tube For posterity, for those making a copy of your tool; the Ideal and exact numbers assuming Ideal 3/8" ID tube would be graduations every 0.555 inches apart Richard |

||

|

|

|