|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Feb 2004

Location: California

Posts: 926

|

Quote:

Velocity curve.. Acceleration is another curve not included in this graph. Yes, increasing lash reduces the time the valve is open. This ramp is way too long almost 30 degrees on the closing side. A GT2 profile would have a 10 to 12 degree long ramp in comparison. The 906 is an extreme example of a very safe profile. it takes 30 degrees to move the valve .008" vs. 12 degrees on the GT2. If I get a chance I will overlay the GT2 with a 906.

__________________

John Dougherty Dougherty Racing Cams |

||

|

|

|

|

Registered

Join Date: Sep 2007

Posts: 500

|

Quote:

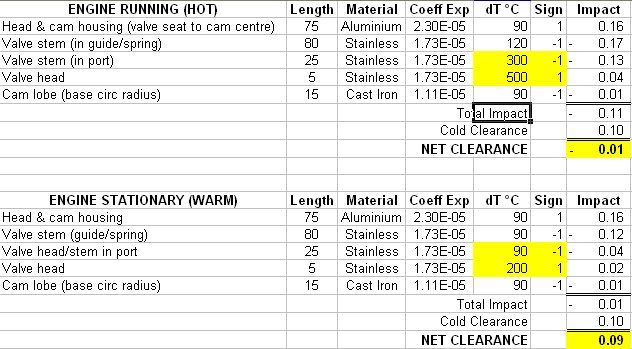

I've not seen cold clearances set any tighter than 0.1mm, and the valve head temperature pic I posted is only indicative - I've not measured it myself - so can't speak as to its derivation, but taken from G&S Valves Ltd UK. I'm only talking about valve/stem length not diameter (and hence not valve to guide clearance) Here's a rough model of what I'm talking about (these are NOT ACTUAL MEASUREMENTS) but simple estimates. (and I've omitted impact of the rocker/and rocker ratio). The datum for the model is the valve seat/head interface (top edge) Sign indicates whether the expansion of the element increases (1) or decreases (-1) clearance. Lengths are estimated effective heat path lengths, in the line of valve action. Note that the valve has been broken into 3 distinct parts, and the sign of each parts contribution to lash. (The valve head actually adds clearance as it is located on its conical seat, but the stem parts decrease clearance with increasing temperature) I had not previously considered the sign of the head as different to the stem parts)  Of course this is a limited model (and I know it shows negative lash by 0.01mm) but you get the impact of the very very hot valve in the running engine, which loses its heat very very quicky when the engine is stopped. Again, if it were as simple as "lash expands with increasing temperature", then try the acid test (set "near to zero" cold valve lash - the follower will still hit the opening ramp at the design velocity - and run the engine and you'll burn all your ex valves.) As Walt picked up - if it's valve cooling you're after, widen the seat and reduce your duration. John D/camgrinder - interesting REAL data on the 906 profile....which I'm still digesting !!! John |

||

|

|

|

|

Registered

Join Date: Mar 2006

Posts: 1,107

|

Hello John,

Personally, I think your estimates do not reflect what actually happens in a running engine. My guess is the actual environment is much more complex than a few numbers on a spreadsheet. The heat and the mass of the parts varys widely. As I said before, my actual measurements and the published valve expansion figures would need to be incorrect by a factor of 10-20 times for the running clearance to be smaller. I have done some more research and all of my sources agree that the actual clearances in a running aluminum block and head engine are greater, by a significant margin, than the cold stationary gap. I believe this explains the unusually tight exhaust valve spec by Porsche. They knew that the expansion of the aluminum head and other parts would result in a much wider gap under actual running conditions. The figures associated with iron engines have much smaller variances. I trust the judgement of the people who design valvetrain to know from experience which is correct. When you make some actual measurements, I would be interested in the results.

__________________

Paul |

||

|

|

|

|

Registered

Join Date: Sep 2007

Posts: 500

|

That's OK Paul - I too trust the judgement of those who design and or have bulk experience. And of course it's much more complex than that - (there's been no discussion on elasticity or dynamics to this point, and I'm certainly not qualified to launch that one...) I'm just trying to increae my knowledge/experience as I go.

So the question remains....if the running clearance just increases with increasing temperature, why not run with zero cold clearance for a nice quiet engine with extended duration as the bonus??? John |

||

|

|

|

|

Registered

Join Date: Mar 2006

Posts: 1,107

|

Again, if it were as simple as "lash expands with increasing temperature", then try the acid test (set "near to zero" cold valve lash - the follower will still hit the opening ramp at the design velocity - and run the engine and you'll burn all your ex valves.)

John, I believe that this test will result in valve failure. But it does not in any way prove that the running clearance is smaller than the cold clearance. Proving the cause of failure takes much more effort. One possibility would be that the actual running clearance opens up, but the amount of seat time is insufficient to get rid of the heat before the surface deteriorates and loses it ability to shed heat. Some things are not so simple.

__________________

Paul |

||

|

|

|

|

Registered

Join Date: Mar 2006

Posts: 1,107

|

After resolving (in my mind at least) why the 911 engine has such a tight cold exhaust valve lash spec, my next question would be why does the aluminum head ALFA twin cam have such a wide (.020") spec at the opposite end of the spectrum ? I know from experience that the similar Jaguar twin cam also has wider clearances when hot, perhaps the sodium filled exhaust valve has an effect, but I'm afraid this may be too OT for this list.

__________________

Paul |

||

|

|

|

|

|

Registered

Join Date: Sep 2007

Posts: 500

|

re ALFA twin cam - the cam is located above the valve & bucket follower (longer distance between valve seat and cam centerline = greater total expansion) The cam is nested lower in the 911 design by virtue of its rockers which decreases the effective length of valve seat to cam centerline. (at least in my mind)

|

||

|

|

|

|

Registered

Join Date: Sep 2007

Posts: 500

|

On that note, I'b be very curious to know the valve lash spec for a 917 or 908 engine which uses the 906 cam profile directly on bucket followers as a comparison point between the 911 (rocker based) arguments above (given the otherwise "similar" head design)

Anyone ??? John Last edited by jcge; 01-10-2010 at 03:11 PM.. Reason: design similitude |

||

|

|

|

|

Registered

Join Date: Mar 2006

Posts: 1,107

|

re ALFA twin cam - the cam is located above the valve & bucket follower (longer distance between valve seat and cam centerline = greater total expansion) The cam is nested lower in the 911 design by virtue of its rockers which decreases the effective length of valve seat to cam centerline.

That would not explain it. The Jaguar twin cam used 0.004" and 0.006" for twenty years and it is a very similar design (Morin bucket pat. 1916) to the ALFA. The Lotus twin cam used similar 0.006-0.008" clearances. The Jaguar clearances were increased to 0.012" for a complex parabolic cam design with very different ramps to produce the exact lift and duration but much quieter operation. The ALFA has a similar construction, a wider VIA, does not have parabolic cams, but uses a 0.020" lash spec. Now that I think about it, the sodum cooled exhaust valve cannot be the reason, because the intake spec is just as wide. I think in the case of Jaguar, competing with the hydraulic lifter cam noise level in a luxury car had more to do with the tight clearances than any technical reasons . But it is a useful example because the MFG was able to reduce noise at much higher clearances by redesigning the cam profile. The ALFA specs are closer to a racing twin cam hemi, 0.016-0.020", and it may just be that the market for sports cars with tuned exhaust notes can tolerate more tappet noise.

__________________

Paul |

||

|

|

|

|

Registered

Join Date: May 2003

Posts: 3,346

|

In Johns spreadsheet above, the clearance for a warm not running engine has decreased from .1mm to .09mm. Since the actual measured value increases instead of decreasing we can infer that there is something wrong with his calculations.

-Andy

__________________

72 Carrera RS replica, Spec 911 racer |

||

|

|

|

|

Registered

Join Date: Mar 2006

Posts: 1,107

|

Andy,

Have you found the source for "The valve lash spec is actually .1mm plus or minus .05mm (.002-.006 inches)." I have search all my (+20) Porsche manuals with no luck. I am certain that the factory never made this recommendation in their publications, and would not advise anyone to go below the factory spec, regardless of the climate. I'm sorry, "It's weather". Paul

__________________

Paul |

||

|

|

|

|

Registered

Join Date: May 2003

Posts: 3,346

|

Sorry Paul, I haven't looked for it. The person that posted it on here in another thread was my friend Tyson Schmidt. Maybe he will see this and have a source. I agree with your comment about not going below factory spec. The question is what is that spec and at what tempuratue. The guidelines I gave I believe to be within the factory spec. Surely you agree that there must be an acceptable variation on the .1mm spec. The .1mm is not listed as a minimum but a target.

-Andy

__________________

72 Carrera RS replica, Spec 911 racer |

||

|

|

|

|

|

Registered

Join Date: May 2003

Posts: 3,346

|

Found the thread. I don't know how to link to it but the title is: Valve clearance smaller for more HP?

-Andy

__________________

72 Carrera RS replica, Spec 911 racer |

||

|

|

|

|

Registered

Join Date: Mar 2006

Posts: 1,107

|

Surely you agree that there must be an acceptable variation on the .1mm spec. The .1mm is not listed as a minimum but a target.

Andy, No, I would disagree, the mfg valve clearance spec is a mininum, unless a range is specified. Target is not a term used for valve clearances. My advice is to try to get them all even and at or above the minimum. On the 911 this is quite easy, on a shim and bucket system it takes many hours and several attempts to get them even. It is much preferable to err on the wide side on a mechanical valve system. In my opinion, advising someone is use less than the mfg spec under any conditions is just bad advice. I don't see anything in that thread that cites a reference. There are no auto engines I know of that have exhaust valve clearances below 0.004", can you find one ?

__________________

Paul |

||

|

|

|

|

Registered

Join Date: Oct 2008

Location: Nash County, NC.

Posts: 8,467

|

The only thing that has any relevance is the running of the engine and that the valves are quiet. The .1 mm is a spec and the old German mechanic always says spec is spec, anything else isnt spec.

Bruce |

||

|

|

|

|

Registered

Join Date: Mar 2006

Posts: 1,107

|

Bruce,

Look at it this way, Say you had an anal, know it all, tech working for you. One day he says, gee, its cold today and I'll ignore the factory spec and crank down the valves to two thousandths. The customer comes back with two burnt valves. Who's fault is it ? Gunter and Heinz ?

__________________

Paul |

||

|

|

|

|

Registered

Join Date: Feb 2004

Location: California

Posts: 926

|

Here is a comparison of the same intake lobe with a hot lash of .008" and .012".

.008" would be the hot lash if you ran .001" or tighter on the lash cold. The higher end of the lift curve is slightly changed, but the time off the seat at lower lifts is increased dramatically. I have had some customers tighten up the lash to .002" to get more top end. I wonder how hot they are getting the cylinder heads and how wide the lash is really getting. http://drcamshafts.com/pp/valve.htm

__________________

John Dougherty Dougherty Racing Cams |

||

|

|

|

|

Registered

Join Date: Apr 2007

Location: wisconsin

Posts: 2,553

|

Thanks for the input, guys...

I just set it at .004. Heat expansion is likely linear. The difference in temp at 40 degrees vs 70 is probably zilch. I was under the impression that the valves/adjusters ran at 200-250 degrees. But a great mechanic pointed out that the valves likely run at 500-600+ degrees, as do the valve stems, etc. The difference in expansion from 40 degrees to 600+, probably isn't much more/less than from 70 to 600+ degrees, assuming its linear... |

||

|

|

|

|

Registered

Join Date: Mar 2006

Posts: 1,107

|

the time off the seat at lower lifts is increased dramatically.

I have had some customers tighten up the lash to .002" to get more top end. I wonder how hot they are getting the cylinder heads and how wide the lash is really getting. Hello John, Anyone that does this has already made the decision that the 15,000 service interval is irrelevent and they are willing to accept the damage. They probably also have narrower seats that stock and will be on to their next engine before long. There is an recent, interesting SAE paper on the sequence of events leading to exhaust valve burning. A lot has to do with the surface finish on the valve and the seat. The valve is eroding the seat surface in a welding and tearing pattern, the surface finish breaks down, the heat transfer is impaired, then the seal breaks down and the hot gas burns a trench. You can probably estimate the additional heat by estimating the percentage reduction in seat time.

__________________

Paul |

||

|

|

|

|

Registered

Join Date: Feb 2004

Location: California

Posts: 926

|

Paul,

These would be racers, not street guys. If you tighten the lash on a set of GT2 cams, you don't pick up as much timing like you do with the 906 profile. Another thing to ponder. the 993 camshafts converted to solid rockers With a cold lash of .004" you will be off the clearance ramp when the engine is hot. Doubling the valve seating velocity.

__________________

John Dougherty Dougherty Racing Cams |

||

|

|

|