|

|

|

|

|

|

|

|

|

|

|

Registered

|

Rocker Arm rebuild Good Rocker or Bad Rocker

Dear All,

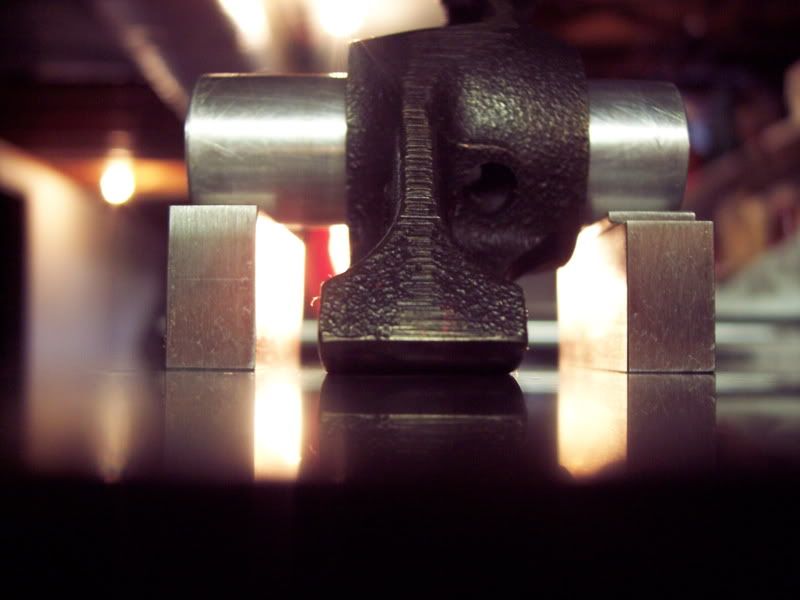

I am a Fan of DIY and I know some poeple don't like my post and will bring it down like the Titanic. I was on Youtube and saw the video of rocker arm rebuild. I am assuming you have seen it as well. I modified my home grinder with an arm and a rocker bushing. I took a bad rocker out of my box. see picture.   I place the rocker on the rotating arm and checked the alignment to the disk. This is very important. See picture.   When you are done with the grinding operation your rocker should look like this.  After this step use some sandpaper with oil and start finishing. I took 240, 400, 1200, chrom polish.   Ready. The surface is still hard like the oem. Any comments Bob |

||

|

|

|

|

abit off center

|

As long as its square with the shaft it should be just fine. You can get some Precision Gage Blocks and check it.

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

Registered

|

Craig

Thank you for the good advice. What kind of hand reamer is the correct one The upper bushing tolerance is 20.013 mm 20,000 / 20.013 mm outer A reamer 20 H8 goes from 20.016 to 20.028 mm 20 H7. has 20.009 to 20.017 mm . Which one are you using? What is the best clearance? BR Bob Last edited by HKZ Bob; 07-16-2010 at 07:37 AM.. |

||

|

|

|

|

Registered

Join Date: May 2004

Location: Worcs UK

Posts: 574

|

Hi Guys.

I don't wish to hijack the thread but would love to know where I can buy replacement rocker arm bushes? Thanks. Andy T |

||

|

|

|

|

abit off center

|

Bob, are you using the stock bushings or the coated bushing that I use? I never could find the stock but I would guess just a ball hone if its a close fit. Thats what I use with the permaglide bushings because you really don't want to cut any of the coating off but more or less just burnish it to fit and the ball hone does this, it does not take much to get the exact fit just a few quick passes and some don't need it at all.

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

GAFB

Join Date: Dec 1999

Location: Raleigh, NC, USA

Posts: 7,842

|

Bob, what are you doing to ensure proper hardness? A LOT of material had to come off to get below that pitting.

__________________

Several BMWs |

||

|

|

|

|

|

Registered

|

Quote:

|

||

|

|

|

|

abit off center

|

When your done make sure you scrub out the bushing with a round brush and brake clean to remove any grit left behind from the hone!!

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

Registered

|

Quote:

How do you think they would be hardend. I assume the were red glowed and than cooled down in oil. Than means to me not only the surface is hard! BR Bob |

||

|

|

|

|

Registered

|

Is there a part number for the permaglide bushings?

Thanks!

__________________

John Flesburg 2016 981 Boxster S.................| 1983 911 Turbo - (White) 1974 911 3.2 - Red Car........... | 1974 914-6 3.2 - (Silver) 1974 914-6 3.2, GT -(Red).......| 1974 914 - 2.7 GT Clone (TBD - Saphire?) 1971 914 (TBD)..................... | |

||

|

|

|

|

Max Sluiter

|

Doesn't this change the rocker arm ratio?

__________________

1971 911S, 2.7RS spec MFI engine, suspension mods, lightened Suspension by Rebel Racing, Serviced by TLG Auto, Brakes by PMB Performance |

||

|

|

|

|

Registered

Join Date: May 2004

Location: Worcs UK

Posts: 574

|

Craig.

Do you sell the permaglide bushings? Thanks. Andy |

||

|

|

|

|

Registered

|

Andy you do high jack this thread 2nd time.

If you would search you would find all answer to your questions. Man do people get so lazy in Singapore. Look here: Refurbished rockers? That was  of you. of you.

|

||

|

|

|

|

Registered

|

|||

|

|

|

|

Registered

Join Date: May 2004

Location: Worcs UK

Posts: 574

|

Sorry if I offended anybody.

That was meant to be a pm to Craig. |

||

|

|

|

|

Registered

Join Date: May 2004

Location: Worcs UK

Posts: 574

|

BTW

Thanks for the contact Craig. Regards Andy |

||

|

|

|

|

Registered

Join Date: Dec 2005

Location: Mount Airy, MD

Posts: 4,299

|

Silly question:

Is the curvature of the rocker face actually just the circumference of the rocker rotation? That's the shape you are grinding, but is that what was put there? I don't know, hence my asking. It was my understanding that the Porsche rockers and actually have a variable rocker ratios the valve is actuated and I would have assumed that was from a non-cylindrical pad surface shape. Please forgive my tearms... Solid geometry was a long time ago. t

__________________

1967 912 with centerlocks… 10 years and still in pieces! |

||

|

|

|

|

Max Sluiter

|

The material removed will change the rocker arm ratio. HKZ Bob is just asserting that the amount of change is negligable, which is resonable if the profile is kept exactly the same as original. How accurate one can be when starting with a worn rocker (such as from plugged spray bars) is debatable, hence HKZ Bob's point that the alignment of the jig and grinder is crucial. There could potentially be much more change in valve lift if the profile is altered than simply removing material distributed evenly across the face. The rocker arm ratio does change dynamically as the arm, cam, and valve move. The leverage arms are from the point of tangency of the cam lobe and rocker pad to the center of the rocker shaft. The other is from the foot of the adjuster and valve stem to the center of the rocker shaft.

__________________

1971 911S, 2.7RS spec MFI engine, suspension mods, lightened Suspension by Rebel Racing, Serviced by TLG Auto, Brakes by PMB Performance |

||

|

|

|

|

Registered

Join Date: Sep 2007

Posts: 500

|

center of generation

Quote:

(C) Porsche -just ignore the arrow..it simply indicates where to measure valve lash. HKZ - firstly I applaud your DIY initiative, and I hope you find this info helpful..... Per tadd's response above - I think you need to be careful using the rocker pivot as the center of generation of the ground arc of the rocker pad... I believe its center lies at a point somewhere "above" the pivot, and grinding from the wrong center will significantly change the valve motion (accelerations etc) Suggest you try and locate this theoretical point using a known good rocker...perhaps fitting a pencil into the rocker bore and rolling the rocker against an angle plate to scribe an arc (involute) on paper will help you locate the real center of the arc (assuming it is indeed just a simple arc....) It's instantaneous center will always be at right angles to the point of contact at the angle plate.... You can then build a jig to mount the rocker and pivot it through this theoretical (as opposed to physical) center Please forgive me if I've misinterpreted the function of your grinding jig and you've already located the true centre of generation... Hope you find this useful - Craig has given you some excellent advise re maintaining parallelism of the ground face to the pivot axis, and you are seem to be already aware of the requirements for surface finish and hardness. John Last edited by jcge; 07-18-2010 at 05:12 PM.. Reason: surface finish and hardness, involute |

||

|

|

|

|

Registered

Join Date: Dec 2005

Location: Mount Airy, MD

Posts: 4,299

|

Jcge:

It's really two things, right... The actual radius of curvature of the pad and where the center is relative to the rocker rotation axis. Could one just replace the grinder with a dial gauge and map the face relative to the rocker rotation? If the values read a fixed number all is golden. If not, then adjustment is required...? HKZ: Have you considered a finer wheel to save all the papering and polishing? Did you lube (coolant) when you were grinding? In answer to your question, they were induction hardened to localize the hardening to just the pad. Don't want the whole rocker brittle. Chris_seven had a brilliant write up on cams in another thread. Awesome info from an in the field metallurgist. t

__________________

1967 912 with centerlocks… 10 years and still in pieces! |

||

|

|

|