Unit arrives with case looking like NEW. Housing removed. Guts have no dust. Turbine spins smoothly. Only issue found is plastic housings on both ends are loose. Found internal stand offs being slightly oversized. Will correct later if this thing works.

Electronic board seems overkill for a blower. Not going to use any of this electronics---is very likely converting AC to DC. Will give RC jet electronics a go (speculating that all brushless motors work on same electronic principles. I may be wrong.)

More meat here compared to RC jet turbines. Unit’s zinc alloy. Down side might be moisture injestion. YouTube’d brushless motors and water. Found submersible maker using brushless motors---with open cases---in salt water. (He flushed them in fresh water afterwards. He also did some mods to motor internals to prevent salt ruination of parts.) Is positive info but offers no guarantee motor in hand will survive moist environment … and if so for how long. Conclusion = moisture won’t be short term killer. Am moving forward with unit.Will incorporate splash shield at intake. Given reasonable duty cycle---am thinking 4 years minimum---at $10 a pop, can stock up on a few refurb’d units. Will do so after proof of concept arrives.

Two critical questions loom at this moment. 1. Will motor in hand work with RC EDF electronics? 2. Will turbine’s noise level be suppress-able enough?

To get motor running... according to RC flight hardware specs, EDF requires Electronic Speed Controller (ESC,) and either a receiver/transmitter or a Servo Tester (ST) to make motor do what you want it to. (In simplified terms, brushless motors operate on an electric pulse system via 3 wires---can see those 3 wires running from ESC to motor, pic above. Pulse speed as distributed by ESC to motor determines motor’s speed. Speed is dictated to ESC by either a receiver/transmitter or in this case an ST.)

According to EDF pilot wisdom, one gets an ESC with a bit more amp capacity than motor uses. At max output, motor in hand draws under 30amps. 40amp (Turnigy Plush unit with a Battery Elimination Circuit---BEC) is purchased… unit in pic above. BEC incorporates a 5v power supply along with the signal wire from the ESC---smal white-red-black wires seen coming out bottom of ESC. As name implies, a BEC does away with need to manually add 5v power supply to either the receiver/transmitter or Servo Tester. (Am total RC flight noob getting school’d.)

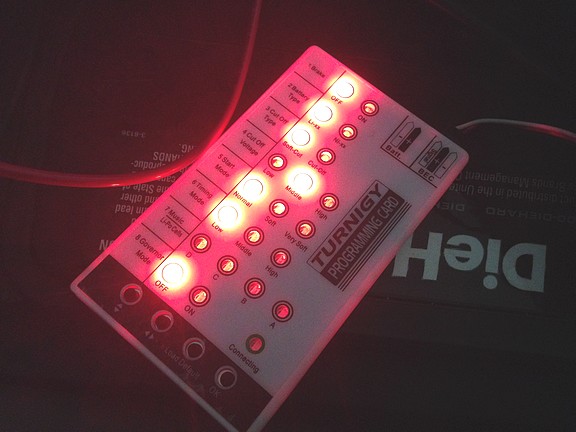

ESCs need to be programmed before use (so ESC knows how to operate.) Can do this easily with programming card, in this case a Turnigy card to match Turnigy ESC. Programming takes just seconds and ESC’s supposedly ready. This card, ESC and ST are a few dollars in total.

Once ESC is programmed, card is detached from ESC and Servo Tester (box with blue light) is connected to ESC. Then power is connected. (Apparently connection sequence of this flyer-gear is very important---hardware is supposedly ruined if wrong connection sequence is done.) ST has knob that turns motor ON and allows for speed/thrust adjustment. Power light ON here is first sign system lives. I turn knob and thrust too lives… albeit exiting intake’s side. To invert, swap any 2 of the 3 wires serving motor. Done…

Thrust is now exiting correctly. Turbine’s speed is controllable via ST. And noise from unit seems manageable given estimated speed of turbine needed to deliver a significant volume of air through condenser.

Challenge of significance is quickly uncovered. If 12v power feeding ESC is disconnected, idea was… when 12v power was resupplied, motor would resume working at speed it was at when previously shut OFF. That’s not happening. Am having to turn Servo Tester OFF, then dial it back up to speed each time 12v power is turned ON. This protocol makes perfect sense as a fail-safe in RC jet pilot world. For Porsche AC app… this protocol is not amusing. In Porsche AC app, ON/OFF power intended to serve ESC unit is related to compressor’s ON/OFF cycle. You see problem? One way to go is to constantly power ESC but this still requires manually turning UP power to ESC each time AC is turned ON. Accepting this is not happening. There’s a way around it. Just need to discover that way. Any ideas? (Anyone know what failsafe circuit will look like? I’ll cut it in ESC.)

Back to bucket building…

Bottom brackets formed & attached. Time to fit-test in wheel well. (Cardboard is over air-exit side of condenser to keep fins from being mauled.)

Air-bucket’d condenser sits as far back as is reasonably possible. There’s maybe ¼” clearance at top rear. Unit tilts top-forward to follow contour of tire. To get a little more clearance between top rear of bucket and fender… will reduce height of rubber mounting doughnuts later. (Bending rear bracket is not an option.) Wing bracket that mounts to fender seam is not yet made/installed.

Bucket’s in/out angle is set to allow just enough clearance for eventual insulation to envelop bucket. Aluminum foil stuffed between condenser and chassis is a casting. Will refer to this foil casting when making screen-guard for air-exit side of condenser. Pointing of air-inlet duct as it is… is not good---should point more towards chassis. Not sure at moment if this is major or minor problem. Need to fit ducting to make final call here.