|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Nov 2016

Location: Orange County/ Los Angeles

Posts: 573

|

Transmission Rebuild: Bearings, Synchros, Sliders, Dog Teeth

Hey guys!

I am starting to get further into the '77 915 gearbox. So far I have all the gearset out and I am visually inspecting all the parts. There are many suppliers (German,OEM,OES,R&S,FAG,Torrington) and some parts are not available in Genuine Porsche which brings me here. I am hoping to rely on your expertise  Need some help choosing parts for: Need some help choosing parts for:Pinion and Main Shaft Bearings Plan on replacing all 6 as my core had unknown mileage, bearing races were tight (sigh of relief) Any experience with German vs Genuine Porsche for the Pinion Bearings? Cost is double for the Porsche ones, not seeing an alternative at this time. Mainshaft bearings, I'm using Fag or Torrington so good here. Dog Teeth Is the Original Equipment Supplier for the Dog Teeth essentially the same as Genuine? What is the latest consensus on Rauch and Spiegal or German for Dog Teeth? Sliders OEM vs OES? Plan on replacing 1-2 and 3-4 slider at the moment as the synchros were toast. Synchros Thoughts on OEM synchros? Thinking I might go Genuine Porsche on the high wear items like 1st or 2nd. Dog Teeth 1st and 2nd (1st teeth questionable, 2nd looks toast, )  Dog Teeth 3rd and 4th (tough call here, look good but might be worth replacing)  Dog Teeth 5th, looks okay, might be worth replacing  Appreciate the help!! |

||

|

|

|

|

Registered

Join Date: May 2008

Posts: 2,948

|

Lot's of helpful 915 pointers at:

Porsche 915 wiki 9-part Tutorial available by scrolling down the left side of any selected page and clicking on "915" under Page Tags.

__________________

Keep the Shiny Side UP! Pete Z. |

||

|

|

|

|

Registered

Join Date: Nov 2016

Location: Orange County/ Los Angeles

Posts: 573

|

Pete, I wouldn't attempt the gearbox without referring to your wiki. Cant thank you enough for it!

After reading through, I still have questions on sourcing components. This post was mainly to gather the most recent opinions and recommendations on bearing, sychros, dog teeth and slider suppliers. |

||

|

|

|

|

Registered

Join Date: Oct 2001

Location: San Carlos, CA US

Posts: 5,549

|

This sounds like you have deep pockets. Bearings are expensive and unless they show wear, why replace them? In my opinion, money is better spent on replacing synchro rings, dog teeth and sliders.

__________________

Porsche 2005 GT3, 2006 997S with bore-scoring Exotic: Ferrari F360F1 TDF, Ferrari 328 GTS Disposable Car: BMW 530xiT, 2008 Mini Cooper S Two-wheel art: Ducati 907IE, Ducati 851 |

||

|

|

|

|

gearhead

Join Date: Nov 2007

Location: Loverland, CO

Posts: 23,595

|

Synchros and sliders, German oem. Dog teeth R&S because they have the proper backcut. German and Porsche teeth have no backcut.

SKF, FAG, Torrington, Timken? Doesn’t matter. Any are fine.

__________________

1974 914 Bumble Bee 2009 Outback XT 2008 Cayman S shop test Mule 1996 WRX V-limited 450/1000 |

||

|

|

|

|

I am my 911's PO

|

Like Matt said...

As far as brands, I had to return several sets of dog teeth because they lacked the proper backcut. As a result they would compress the synchro too much and fail the minimum diameter check. I ended up using the Rauch & Spiegel brand.  References I found valuable... Pete Zimmermann tutorial (the bible) Forum Categories - Porsche Wiki Pelican thread by "evan9eleven" (long, detailed, lots of info on differential set up) Matt M. and Jon B. contrib 915 rebuild and ITB/EFI project, here we go! Pelican thread on rebuild "Gordo's Rebuild" (long, detailed, lots of assembly details) Gordo's 915 Transmission Rebuild |

||

|

|

|

|

|

Registered

Join Date: Nov 2016

Location: Orange County/ Los Angeles

Posts: 573

|

Well noted, backcut is needed!Will stick to R&S for dog teeth, right now the plan is to replace 1-2 and potentially 3-4 if after teardown they shown signs of wear.

It is $1000+ in bearings! Wish I could avoid the cost but as far as I know there is no real way of checking if the bearing is good. The last thing I want is to assemble the gearbox and find out there is a howl because of a worn bearing. The bearing races feel smooth, despite the color differences. There is no evidence of wear from where the bearing rides on and the non loaded surface. The races are fully seated in the housing too.

|

||

|

|

|

|

Registered

|

Quote:

Quote:

I want to get this aspect correct for my gearbox overhaul.

__________________

81SC Coupe Tony Kart/Yamaha |

||

|

|

|

|

Brew Master

|

I'd think when they say "back cut" that it means there's a slight taper to the cut. I would think the taper would be from the top of the tooth to the bottom. From looking at a set of new dog teeth when I installed mine, I don't think it's something you'll be able to post a pic of because the back cut would be so minimal that a camera or the naked eye isn't going to pick it up. I know I didn't notice any real difference but I really wasn't paying attention that closely. I was more worried about getting all that protective goo off the teeth and sliders

__________________

Nick |

||

|

|

|

|

Registered

Join Date: Feb 2003

Location: Kailua, Bend, & Tamarack

Posts: 1,618

|

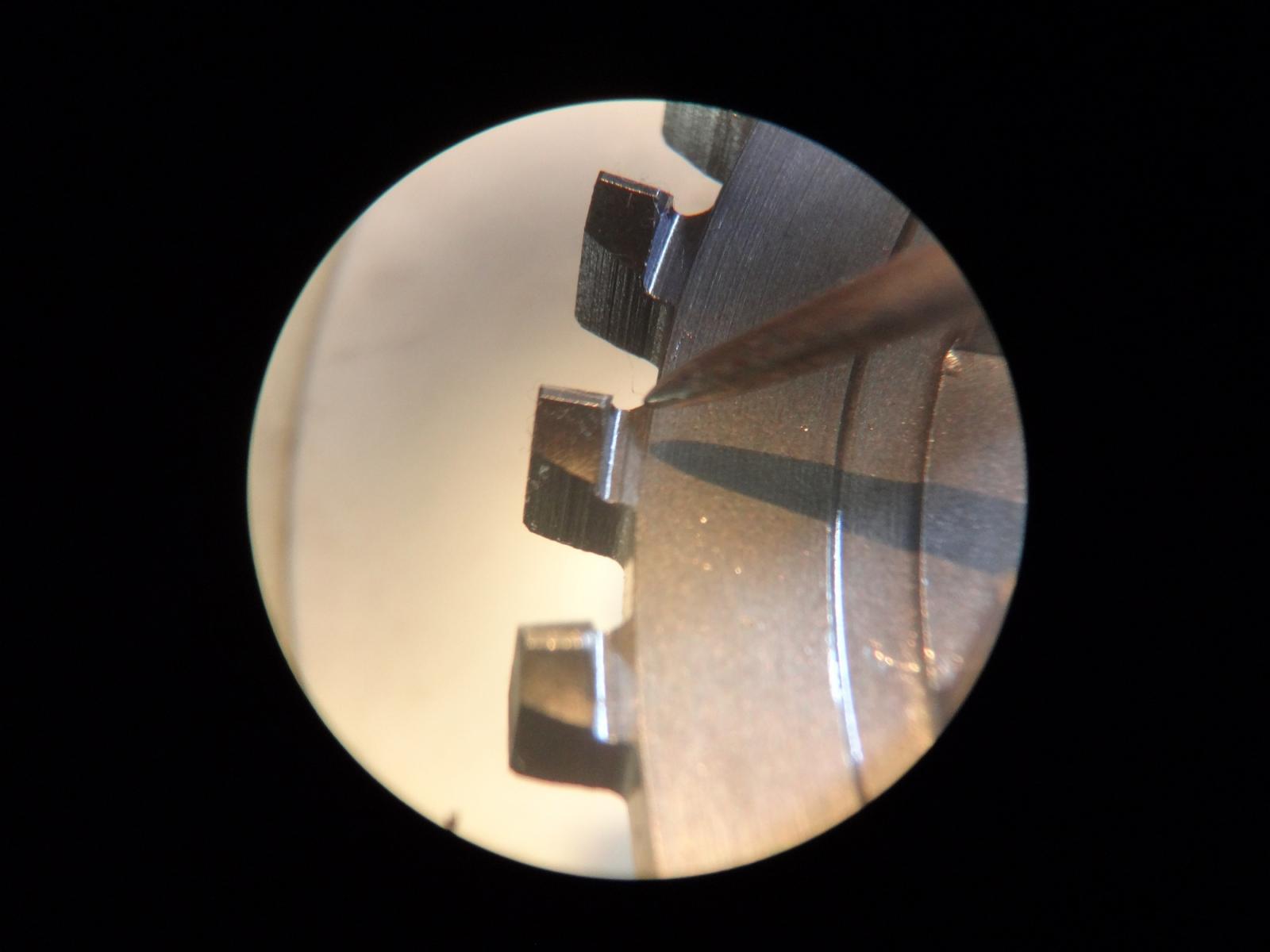

This 9* angle is what contacts & compresses the synchro ring (better seen on the tooth above the one I'm pointing at):

|

||

|

|

|

|

Registered

Join Date: Oct 2001

Location: San Carlos, CA US

Posts: 5,549

|

Quite easy to see, actually.

__________________

Porsche 2005 GT3, 2006 997S with bore-scoring Exotic: Ferrari F360F1 TDF, Ferrari 328 GTS Disposable Car: BMW 530xiT, 2008 Mini Cooper S Two-wheel art: Ducati 907IE, Ducati 851 |

||

|

|

|

|

Brew Master

|

You have EXCEPTIONALLY good eyes if you can see a 9 degree taper in less than 1/2 inch.

__________________

Nick |

||

|

|

|

|

gearhead

Join Date: Nov 2007

Location: Loverland, CO

Posts: 23,595

|

It’s easy to see if you have a cut one and an uncut one side by side.

__________________

1974 914 Bumble Bee 2009 Outback XT 2008 Cayman S shop test Mule 1996 WRX V-limited 450/1000 |

||

|

|

|

|

Registered

Join Date: Jan 2015

Location: Stow, MA

Posts: 584

|

Quote:

Quote:

Quote:

Quote:

I suspect you know this already. But be sure to validate both the shape of the engagement tooth (pointy bits) as well as the installed diameter of your new synchros. The synchos wear the dog teeth inside bits, and if it measures out of spec, replace. Good luck!

__________________

Kevin Catellus Engineering catelluseng@gmail.com http://www.catellusengineering.com https://www.facebook.com/catelluseng/ Last edited by kevingross; 05-24-2020 at 06:21 PM.. |

||||

|

|

|

|

Registered

Join Date: Feb 2003

Location: Kailua, Bend, & Tamarack

Posts: 1,618

|

.

I couldn't edit/replace my previous photo, so to further clarify: This shows the tiny little 9* angle on the inner tip ..  .. and how that angle is supposed to approximate that of the Synchro ring.  Here's the area of the shift sleeve (slider) that wears/burns ..  .. forming a sharp little lip on each slider tooth, essentially "closing the gap" between teeth, and eventually causing balky shifting.  One trick to perhaps get a bit more time between rebuilds AND to help assure smooth shifting from the gitgo is to Dremel the edges of a new sleeve ..  .. paying closest attention to the area where that little lip will eventually form.

|

||

|

|

|

|

Registered

Join Date: Oct 2015

Location: EastCoast

Posts: 664

|

Just hand my gearbox rebuilt. Change all parts that need replacement. You won’t regret it. My 915 shifts like butter. Feeling like I’m driving a different Porsche

) )

|

||

|

|

|

|

Registered

Join Date: Nov 2016

Location: Orange County/ Los Angeles

Posts: 573

|

Took a look at the 5th gear dog gear assembly and looked closer at the backcut you guys are mentioning. I was able to see the backcut on one of the exposed teeth with the help of Geary's great explanation.

Measured the synchro in its installed state and it comes in at 76.31mm which was about the average from 4-5 measurements. Measured at the largest OD. Spec is 76.12-76.48.  Does it make sense any sense to remove the sychro, press the dog teeth out if the synchro checks out? The ugly: the needle bearing cage was cracked, this needs replacement. The needle was still in the cage when I removed it, I removed it for the picture. Not too bad so far.  Washer looks to have some wear marks around the edges, could be from the manufacturing process, not sure...  Thanks for sharing your years of experience, glad I can learn from you all. More teardown coming up this week! Quote:

Last edited by edjrbashian; 05-25-2020 at 10:47 PM.. |

||

|

|

|

|

Registered

|

Quote:

Geary, Thank you for clearing up this part of the 915 puzzle, this part of the equation is much easier to understand now & how to identify the recommended dog teeth.

__________________

81SC Coupe Tony Kart/Yamaha |

||

|

|

|

|

|

Registered

Join Date: Feb 2003

Location: Kailua, Bend, & Tamarack

Posts: 1,618

|

Yes, a picture is worth a thousand words .. The reason some manufacturers leave this angle uncut is because it's meant to be stone ground AFTER the ring has been installed onto the gear. This assures that the synchro ring is held concentric to the gear bore. But in "real world", few shops have this capability, AND concentricity is usually close enough to warrant pre-grinding this REQUIRED 9* angle.

|

||

|

|

|