|

|

|

|

|

|

|

|

|

|

|

Enthusiasm > Expertise

Join Date: Mar 2011

Location: Outside Philly

Posts: 606

|

The friction should be tuned to spec regardless of whether the puck is plastic or not. More on this soon; Dave the Slave is going to be experimenting with springs, shims, and drag while I'm at auto week.

Your approach should work fine, but it permanently alters the geometry of the donor puck, so one cannot reverse the decision to use a plastic face. I hate to consume an original part with a hack, even if it is an elegant hack.  If it seems that we need a different solution to fastening the face, I will probably just turn new pucks out of soft metal or plastic. The cost and performance of facing and fitting two parts of different materials (by any method) probably exceeds the cost of boring one part and then simply cutting it off. Finally, if I'm a Puck Whisperer, I want to make a batch and then ship them out to users, job done. Similarly, if I want a puck upgrade, I don't want to leave my car on stilts while I send my donor puck off and wait around for the Whisperer's renovation and return. But keep the feedback and ideas coming. I'm really looking forward to seeing how these perform and finding the right solution for the next 40 years. I'm putting new R&Ps into my rebuilds and I just can't stomach the thought that my shiny new steel could end up heavily scored. It's bad enough that I have to suffer worn brake rotors!

__________________

Red Dog Motorsports |

||

|

|

|

|

Registered

Join Date: Oct 2003

Location: Northside, Brooklyn

Posts: 2,361

|

Kind of reviving an old post here, but good info never gets old. Thanks to all original posters :Tim H.. & KTL et all...

Polish your puck! I think the puck can be resurfaced. Any significant amount of metal removed can be 'made -up' by shimming the puck with a washer verso/ spring side.. Lashing spec instructions should be followed 0.008" is the norm for 914 not sure if its the same for 911. Clymer manual posted by KTL is cool to look at. Since the puck on my car and not worn just a slight trace of marks showing contact with the moving part I might just "make it smooth" again with 220 grit 300 grit 400 grit and so -on. (Lay the sandpaper face -up on a flat surface, a thick piece of glass works.) Knocked the drive axel gear out thru the bearing with a drift. Everything now removed from rack starting re-assembly forgot the exact location of rubber "o"ring..drat, had to re-assemble. All is good now, and greased , i used Castrol hub and bearing grease. Re-assembly is as tricky as dis-assembly,but it all kind of makes sense in the end-only one way to do it.

__________________

jt '83 SC '96 M3 6 Bicycles 2 Sailboats Last edited by Kraftwerk; 03-07-2016 at 11:04 AM.. |

||

|

|

|

|

Enthusiasm > Expertise

Join Date: Mar 2011

Location: Outside Philly

Posts: 606

|

We went ahead and switched to making solid PTFE POM pucks that can be bored to exactly fit the original springs. Plenty of material, ignore drag, perfect fit, very slippery, and zero wear to the rack. I'm very happy with these.

__________________

Red Dog Motorsports |

||

|

|

|

|

Stranger on the Internet

Join Date: Apr 2004

Location: Bradenton, FL

Posts: 3,244

|

Well, that was a quick 10 years...

I just pulled the rack out to change the fuel lines, and figured I spiffy up the steering while I'm in there. Since I rebuilt the rack 10 years ago, it still feels pretty good. The tie rod boots were broken, and I have to replace the inners and outers, but the rack seems OK. I am likely going to pull it back apart to lube it up and change the bearings. Anyone find a source for the pucks yet? (Else, I may just trim it a bit on my lathe). Anyone ever grease the u-joints in the steering column? I guess it won't hurt to re-lube them too.

__________________

Patrick E. Keefe 78 SC Last edited by patkeefe; 10-14-2015 at 06:01 PM.. Reason: added a line |

||

|

|

|

|

Registered

Join Date: Oct 2003

Location: Northside, Brooklyn

Posts: 2,361

|

Pat,

Good to hear your rebuild lasted ten years. My rack was totally stock untouched since 1983 and it was all still pretty good in there, minus the some of the grease... which must have seeped out..I polished my puck down a bit so I got the 'scrapes' out of it, "groove" would be an exaggeration, just some deep scrapes.. now history. The rebuilt rack is a bit ' stiff ' now that its packed with grease.. maybe there is too much grease in there? I noticed on another rack from a race -car there was LOTS of play: it was very L o o s e....

__________________

jt '83 SC '96 M3 6 Bicycles 2 Sailboats Last edited by Kraftwerk; 03-07-2016 at 11:05 AM.. |

||

|

|

|

|

Registered

Join Date: Jun 2011

Location: Placerville, CA.... You know, the only place on Highway 50 between Sacramento and Lake Tahoe the you find signal lights. Above the fog most of the time and I can see the stars of the Milky Way 8 out of 10 nights. Kinda cool.....

Posts: 6,329

|

Quote:

Are you going to be making these available for other members? I plan on pulling the rack tomorrow to start the rebuild. Our 78SC had 260k on it ant the rack is the last part that needs to be refreshed. Hope to start the reassembly soon. Cheers

__________________

"What the hell is an Aluminum Falcon??" -Palpatine (Robot Chicken) 1978 911SC Targa Working Projects: 1968 912 |

||

|

|

|

|

|

Enthusiasm > Expertise

Join Date: Mar 2011

Location: Outside Philly

Posts: 606

|

Quote:

The needle bearing assembly that runs around the shaft leading to the guibo suffers from a similar wear issue, so I am making replacements for those as well. I know chris-seven came up with a sexy update to replace that problematic (and expensive) part, but, well, I haven't paid for sex yet and I'm not about to start.

__________________

Red Dog Motorsports |

||

|

|

|

|

Schleprock

Join Date: Sep 2000

Location: Frankfort IL USA

Posts: 16,640

|

Quote:

The HK1712 bearing I chose is their Kit8628, because it looked exactly like the original bearing Porsche used VXB Bearing online: Search Results The shaft seal is a 17x23x3 https://metricsealsinc.com/store/items/Products.aspx?store=&currpage=1&searchby=&lookfor=wao-17&searchMethod=Contains

__________________

Kevin L '86 Carrera "Larry" |

||

|

|

|

|

Registered

Join Date: Jun 2011

Location: Placerville, CA.... You know, the only place on Highway 50 between Sacramento and Lake Tahoe the you find signal lights. Above the fog most of the time and I can see the stars of the Milky Way 8 out of 10 nights. Kinda cool.....

Posts: 6,329

|

SC Steering Rack DIY Bearing Replace

Quote:

Wow! Thanks!!!! I'll will be dropping the rack today and try to get those dimensions asap. I don't know if I'm jumping the gun with this but since the rack has never been addressed in the whole 260k miles, I'm kinda prepping for the worst. In my mind, it wouldn't make sense to refresh the suspension and not take a look at the rack. At least that's how I'm justifying it.... Thanks again Trevor Sent via Jedi-Kung-Fu-Panda mind trick by the cat

__________________

"What the hell is an Aluminum Falcon??" -Palpatine (Robot Chicken) 1978 911SC Targa Working Projects: 1968 912 Last edited by bugstrider; 10-15-2015 at 09:10 AM.. |

||

|

|

|

|

Registered

Join Date: Feb 2004

Location: UK

Posts: 2,230

|

I haven't followed this thread but it is quite interesting.

We started making the outer shaft replacement with a bronze bush instead of the INA needle roller because using a bearing with a 14000rpm capability that whenever you dismantle this part of the column has rollers that are always jammed and full of crud so they skid on the shaft. You also have to pull the old component apart and generally wreck the seals to replace the needle rollers. The later bonded rubber part at more then $100 is even more difficult to pull apart and repair. We chose a bronze bearing because they are much 'kinder' to the steering shaft which is not fitted with a hardened track and they are much more suitable for the oscillatory motion which occurs in a steering shaft. I would also agree that paying for sex is a real pain but $30 each - give me a break. You could spend more buying a blonde a drink  The body of the bush is made from 7075-T6 Aluminium and hard anodised. The bush in Oilite which has been oil impregnated we have fitted a pair of R21 Rotary seals to keep the crud out - and they fit correctly. The rubber housing is still available from Porsche for $15 or you can buy a harder PU housing from Powerflex.   We have been making the Rack Support Pad (Puck) for about 5 years now. The body is again 7075-T6 hard anodised and a natural Delrin Pad fitted to the support face in the same manner as the standard early component. We make both sizes for early and late racks and they locate the standard springs in an identical manner to the original. We also supply a stainless steel shim to sit between the spring and the body of the 'puck' to eliminate any chance of fretting. We used a metal body because on the later punks there is always a substantial 'witness' where they have been located in the rack body and it we didn't want to risk using a material that could be eroded over time and lose its location.   We have also been manufacturing replacement rack support bushes which are a Bi-Metallic Bush with a bonded rubber casing that are identical to the original part. The rubber is an HNBR and is 85Shore A which is around 10 points harder than the standard bush. We make both the 30mm ID bush for the early rack and the 29mm ID bush for the later rack.

Last edited by chris_seven; 10-15-2015 at 10:06 AM.. |

||

|

|

|

|

Enthusiasm > Expertise

Join Date: Mar 2011

Location: Outside Philly

Posts: 606

|

Chris, if I'd had your parts in front of me, I'd have been happy to buy the blonde a drink. You were supposed to ship me a box of this stuff for US distribution!

__________________

Red Dog Motorsports |

||

|

|

|

|

Registered

Join Date: Feb 2004

Location: UK

Posts: 2,230

|

Andy,

I would be very happy to send you some parts as we just don't have time to distribute them effectively. I clearly misunderstood your last e-mail |

||

|

|

|

|

Stranger on the Internet

Join Date: Apr 2004

Location: Bradenton, FL

Posts: 3,244

|

Second edit:

I don't think there is a seal like the 914 racks with two ball bearings have. Just an O-ring. Does anyone have a part number for the grease seal? I took my rack back apart and realized it doesn't have a seal in it. I may have left it out last time I did this; it did not seem to have caused any problems. I would just as soon put the seal back in this time, however. Edit: on second thought, is there even a seal over the bearing. It looks like the bearing is simply sealed by the steel caps, with an O-ring over the needle bearing. That sound right?

__________________

Patrick E. Keefe 78 SC Last edited by patkeefe; 10-18-2015 at 08:47 AM.. |

||

|

|

|

|

Registered

Join Date: Dec 2002

Location: So Cal and So Oregon

Posts: 2,208

|

So Chris_Seven , how does a person from the US buy parts from you?

|

||

|

|

|

|

PhD on Pending Projects

|

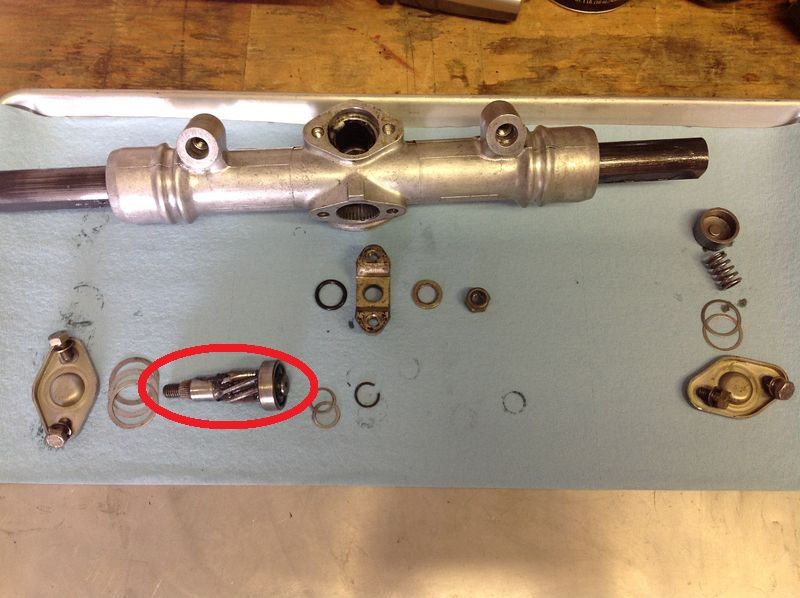

On to cleaning the steering rack... also decided to open it up and clean and replace the old grease. Question that I have is (and probably missed it in this thread) how do you remove the gear/shaft/bearing assembly? Do you just tap it out? Any circlips holding it in place?

This is what it looks like when you take it out... I just need to make sure that I do not damage anything in the process... so looking for clarity on how it comes out.  Replacement bearings #1712 and #6202 from EB Atmus Co. in the US. Search for 1712 | E.B. Atmus Co., Inc. Search for 6202 | E.B. Atmus Co., Inc. HK-1712 NEEDLE BEARINGS-SHELL TYPE-OPEN 1 6202-SKF SINGLE ROW BALL BRGS 1 Bearings, Motion Control, Power Transmission, Pneumatics | E.B. Atmus Co., Inc. EDIT: Nevermind, found a thread that calls this out clearly!!! rebuilding the steering rack and adding "turbo" tie rod ends Quote:

__________________

Drive safe! 1967 - Porsche 912 1981 - Porsche 911 SC 1991 - Porsche 911 C4 Wide-body Cabriolet |

||

|

|

|

|

Registered

Join Date: Oct 2003

Location: Northside, Brooklyn

Posts: 2,361

|

Don't forget to check your bushing on the shaft...

"The body of the bush is made from 7075-T6 Aluminum and hard anodized. The bush in Oilite which has been oil impregnated we have fitted a pair of R21 Rotary seals to keep the crud out - and they fit correctly." ^Sounds like a great upgrade , where can I find one? The puck itself can be polished if it has signs of "fretting" .. : ) On the other hand I would love to try one of those " PTFE POM pucks" to compare drag/lash. Also, gaskets for the two covers can be cut out of 'gasket material'. Gaskets are, in fact pictured in the exploded parts-diagram from the factory (?) manual. Keep in mind, the thickness of the gasket will change the "lash-spec" or 'feel' of the spring loaded bushing.. On the side with the puck, where it is spring loaded, I suggest taking some stress off the little cover-plate by using a c-clamp to hold the cover-plate on while you thread those two bolts (which hold the cover on) Otherwise you could cross-thread or strip the bolts. I am no expert, this is just stuff I thought about while overhauling two racks recently. It was fun!

__________________

jt '83 SC '96 M3 6 Bicycles 2 Sailboats Last edited by Kraftwerk; 01-27-2016 at 12:19 PM.. |

||

|

|

|

|

PhD on Pending Projects

|

Cool, thank you! I do have a new bushing for the steering shaft.

For gasket, I was planning on using Loctite 574. The gasket that I saw on the cover was almost non-existent... if there was one it was very thin, reason why I think that just 574 would do the trick. The two bearings (1712 & 6202), I got those from Amazon and should arrive tomorrow.  Quote:

__________________

Drive safe! 1967 - Porsche 912 1981 - Porsche 911 SC 1991 - Porsche 911 C4 Wide-body Cabriolet |

||

|

|

|

|

Registered

Join Date: Mar 2007

Location: Boyertown, Pa

Posts: 251

|

Don't forget to seal the giant plastic boot where it goes against the rack. Since it is hard plastic, it won't seal itself and any gaps will allow water to get into the giant funnel shape at the top of the rack, putting it exactly where you don't want it.

__________________

Failure is not an option 78 SC, 06 Cayman S, 74 Targa, 1971 BMW R75, 1975 BMW R90S, 1983 BMW R100S, 2004 BMW R1200GS, 1974 Ducati 750 GT, 1974 Ducati 750 Sport, 1986 Ducati MHR Mille, 1995 Ducati 916, 1994 Bimota DB2, 2001 Tri 955 RS, 1970 Norton 750, 1975 Hon 400 F, 1971 Hon 750, 1967 Duc 250, 2016 Tri Thruxton |

||

|

|

|

|

Registered

|

And have you considered replacing the retainer rings that hold the bushings in place? The chap who started this thread bought a large batch and sells them cheap. I'm going to go back and do mine as they're cheap insurance.

|

||

|

|

|

|

Registered

|

Quote:

Juergen |

||

|

|

|