|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: May 2000

Location: Los Alamos, NM, USA

Posts: 6,044

|

Need 901 transmission tool sizes

I have been asked to assist a young friend in early June with the refurbishment of a 901 transmission from a 914 (1st and 2nd gear synchros require renewal). I note from the shop manual that a couple of special sockets are required and we seek dimensions/sizes so we can begin fabricating them ahead of time. 1.) We need the hex size of the "stretch" bolt that screws into the front end of the output shaft; this "stretch" bolt has an extension from the head that forms the speedometer drive. We would like to make the required extended socket by welding a piece of tube onto a standard socket but need to know the tube ID required to slip over the speedo drive gear. 2.) We also need to know the hex size of the nut on the input shaft that also requires a special socket. Many thanks if you can give us a head start with this information. Cheers, Jim Sims

|

||

|

|

|

|

Registered

Join Date: May 2000

Location: Los Alamos, NM, USA

Posts: 6,044

|

I have one piece of information indicating that the input shaft nut size is 32 mm but am seeking further confirmation.

|

||

|

|

|

|

Registered

Join Date: Dec 2003

Location: Arapahoe County, Colorado, USA

Posts: 9,032

|

Jim,

Yes the nut on the input shaft is 32 mm hex. The original P252 has a step at the ˝” drive end with a loose fit over the pilot bearing surface of the input shaft. That step is about 310 mm from the end of the socket. I’ll measure better tomorrow. The stretch bolt with the speedometer drive is 30 mm hex. The total inside length must be greater than 62 mm to clear the speedometer drive. If you can find a broken 914 transmission casting, you can band-saw out the center bulkhead that supports the pinion and input shaft roller bearings. You can trim it to make an exact replica of P260. You will need a bad 1-R sliding sleeve. Grind off 5 reverse teeth. This allows you to shift into both 2nd and 1st to unscrew the nut on the 1-R end of the input shaft. This puts less stress on the assembly. Without grinding the teeth, a socket won’t fit on the input shaft nut. You want to do this operation with the gear cluster still in the case. Find a bad 1st gear I (fixed). You can weld it onto a plate to make a P256. Remember to measure the paper shims between the intermediate plate and the main casting. Your mission is to take images for the Forum. Best, Grady

__________________

ANSWER PRICE LIST (as seen in someone's shop) Answers - - - - - - - - - - - - - - - - $0.75 Answers (requiring thought) - - - - $1.25 Answers (correct) - - - - - - - - - - $12.50 |

||

|

|

|

|

Stressed Member

|

Jim-

I purchased a 30mm deep socket that worked just fine for the stretch bolt. I think I paid about $13 for it (new). -Scott

__________________

'70 911E short stroke 2.5 MFI. Sold    '56 Cliff May Prefab |

||

|

|

|

|

Registered

Join Date: May 2000

Location: Los Alamos, NM, USA

Posts: 6,044

|

Thanks to both of you!

"You will need a bad 1-R sliding sleeve. Grind off 5 reverse teeth. This allows you to shift into both 2nd and 1st to unscrew the nut on the 1-R end of the input shaft. This puts less stress on the assembly. Without grinding the teeth, a socket won’t fit on the input shaft nut. You want to do this operation with the gear cluster still in the case." I'll need to study the arrangement further to understand this need but can't the forward nuts be removed/reinstalled by locking the transmission into two gears at once or would this be the source of too much "stress on the assembly" "Find a bad 1st gear I (fixed). You can weld it onto a plate to make a P256." Again, I don't understand this tool (the 901 transmission section of my shop manual is loaned out) but couldn't a suitably modified used clutch disk be used to react torque from the other end of the input shaft? Thanks again; we'll take pictures. Jim |

||

|

|

|

|

Registered

Join Date: Dec 2003

Location: Arapahoe County, Colorado, USA

Posts: 9,032

|

Jim,

"You will need a bad 1-R sliding sleeve. Grind off 5 reverse teeth. This allows you to shift into both 2nd and 1st to unscrew the nut on the 1-R end of the input shaft. This puts less stress on the assembly. Without grinding the teeth, a socket won’t fit on the input shaft nut. You want to do this operation with the gear cluster still in the case." I'll need to study the arrangement further to understand this need but can't the forward nuts be removed/reinstalled by locking the transmission into two gears at once or would this be the source of too much "stress on the assembly" Actually this is where a used clutch disc hub modified to be a P37 can accomplish the same thing. Grinding some teeth off an old 1-R sliding sleeve is just easier. I have both. "  " "© Dr. Ing. h.c. F. Porsche A.G.  "Find a bad 1st gear I (fixed). You can weld it onto a plate to make a P256." Again, I don't understand this tool (the 901 transmission section of my shop manual is loaned out) but couldn't a suitably modified used clutch disk be used to react torque from the other end of the input shaft? No, this is where you have the input shaft stack out of the intermediate plate and need to loosen or tighten the 32 mm nut using P252 or equivalent. The P256 or equivalent is fixed in a vice so the input shaft assembly is vertical. This allows you to use both hands on the wrench and P252 to not put any bending moment on the input shaft. The Factory Workshop Manual (FWM) shows this operation with the shaft horizontal. I believe this contributes to the failure of the input shaft at 1st gear.   "  " "© Dr. Ing. h.c. F. Porsche A.G. To make a good reproduction of P256, take a piece of steel (100 x 60 x 20 mm) and drill a hole slightly larger than 27 mm in the flat (100x60) side. With proper preparation, brazing or silver solder will work fine. Of course machining the teeth off and TIG wilding will look better than the original. The socket I have for the pinion stretch bolt is a Hazet 900TZ – 30 mm. It properly clears the speedometer drive. Its depth is 62.8 mm. Best, Grady |

||

|

|

|

|

|

Registered

Join Date: May 2000

Location: Los Alamos, NM, USA

Posts: 6,044

|

"No, this is where you have the input shaft stack

out of the intermediate plate and need to loosen or tighten the 32 mm nut using P252 or equivalent. The P256 or equivalent is fixed in a vice so the input shaft assembly is vertical. This allows you to use both hands on the wrench and P252 to not put any bending moment on the input shaft. The Factory Workshop Manual (FWM) shows this operation with the shaft horizontal. I believe this contributes to the failure of the input shaft at 1st gear." For the 915 version of this tool I used an old clutch disk in which I drilled out four of the existing holes and inserted bolts; on the other side I screwed onto the bolts, long coupling hex nuts and tightened and shimmed them so the flats were parallel to each other. The disk is then placed in my large, heavy duty bench vise clamping onto the four coupling nuts with the axis of the splined hole oriented vertically. This permits the gear stack/input shaft to be vertical while the nut is being loosened/tightened. One person typically mans the custom socket (equivalent to P252) with the breaker bar or torque wrench and another supports the shaft against the reaction. Even vertically it is difficult to achieve pure torsion without some bending moment. My Porsche mentor took my modified 915 clutch disk and cut off the old friction disk portion (leaving only the center core) to make it more compact and he further improved it by welding a cup underneath (with a punch knock out hole if the shaft becomes stuck in the splines) to support the end of the input shaft so it engages the clutch disk splines at the correct location and not fall through the modified clutch disk. Can we not make something like this for the 901? Scrap 901 transmission parts may not be too common around here. I'll post some images of the modified clutch disk tonight. Thanks again, Jim |

||

|

|

|

|

Registered

Join Date: Dec 2003

Location: Arapahoe County, Colorado, USA

Posts: 9,032

|

Jim,

The reason for the P256 – P252 arrangement is so you can torque the 32 mm nut on reassembly.  Here the torque wrench is blue and I would pull with my right hand (red arrow) while supporting (green arrow) the tools with my left hand. This is a case where a "T" cross-handle torque wrench would be ideal. In practice there is a slight "wobble" play between the 1st gear splines on the input shaft and the internal splines of P256. If you maintain that wobble while you torque the nut, you are assured that you aren't bending the input shaft at the 1st gear end. You can use the P37/clutch disc method for unscrewing using a 32 mm box wrench. The only way I can think to use the P37/clutch disc method for reassembly torque is to make a 32 mm box wrench similar to this:  This is a 41 mm for torque on the 906-935 cam nuts. I also made one for the 46 mm 911 nuts. You just have to compensate for the extra radius. This is a SnapOn X520A. The best, easy solution is to take a 32 mm 6-point socket and cut it apart. I would use a SnapOn IMML320 impact socket (list $36.65) to make a higher quality tool than P262. All you need is an appropriate length pipe piece to weld in the middle. Too long is just fine. Best, Grady |

||

|

|

|

|

Registered

Join Date: Nov 2004

Location: Greater Metropolitan Nimrod, Oregun

Posts: 10,040

|

Grady, Jim -- can you also post where or for what tools can one maybe make them or make jigs out of cheaper, easier to work with materials? Say, like plexiglass? For example, I know where one person made a jig tool out of plywood -- he only used it once, just as many of us will -- we won't be redoing tranny after tranny...

also, re the 32mm 5 pt. socket -- can you sketch where the handle would attach?

__________________

"A man with his priorities so far out of whack doesn't deserve such a fine automobile." - Ferris Bueller's Day Off |

||

|

|

|

|

Registered

Join Date: May 2000

Location: Los Alamos, NM, USA

Posts: 6,044

|

See below for the method/tools I use for the 915 input shaft loosening/tightening. I am proposing to modify a 901 clutch disk and a 32 mm socket and use them the same way. The wood dowel is a prop for an input shaft. Also with 915 transmissions I have engaged two gears at one to eliminate the need for a P37 holding tool without any apparent ill effect. Can the same be done with a 901 transmission?

|

||

|

|

|

|

Registered

Join Date: May 2000

Location: Los Alamos, NM, USA

Posts: 6,044

|

"-- can you also post where or for what tools can one maybe make them or make jigs out of cheaper, easier to work with materials? Say, like plexiglass? For example, I know where one person made a jig tool out of plywood --"

This can only work if the forces are low (such as seal installation) or the loads can be spread out over a large area (the plywood form to react forces through the transmission housing) or if the loads are mostly compression loads. The high local loads at splines and nuts pretty much dictate the use of steel tools. That being said, I have used PVC, ABS and copper pipe and fittings to install seals and act as reaction bases as I press apart the gear stacks using a hydraulic shop press. The young man we are helping just brought his new to him 914 by to show me; he is very excited and enthusiastic. Thanks for the help. Last edited by Jim Sims; 05-17-2006 at 08:09 PM.. |

||

|

|

|

|

Registered

Join Date: Dec 2003

Location: Arapahoe County, Colorado, USA

Posts: 9,032

|

Jim,

Good for you helping a young new Porsche owner. Is he on Pelican? Yes, that will work. Just make another that is 32 mm for the 901 to replace the P252 like the 41 mm you made for the 915 to replace the P252a. A 901 clutch to replace the P37 just like the 915 clutch to replace the P37a. Yes, putting the cluster in two gears is just fine so long as the two shafts are supported by their bearings at both ends. The 2-gear method tries to force the shafts apart. The 4-point bearings don’t like to be bent. When I use the 2-gear method, I always have the gear cluster in the transmission casting (or intermediate tunnel for 915) or use the P260 (P260a for 915) guide plate to support the bearings. Randy, in this case it isn’t much more work to build a replica of a P-tool as good or better than the original. Yes, a quality socket, some steel tubing, lathe work and welding are more expensive. Even if you use it once, you can sell to another Pelican and recoup your cost. While Pelican doesn’t carry these, they may be able to get them. Baum has the P252 in stock for $84.50 retail. There are a few things where a less expensive material may be better. For example I think there is an aftermarket plastic P260. I suspect this might be easier on the bearings but not as dimensionally stable or long lived. Here is one of the first P-Tools I built – probably early ’69. A little crude but has worked well for 35+ years of regular use. This grabs the syncro dogs at the circlip ring to press off the dogs from the gear. In ’72 I made one for 915 1-2 gears. (The extra little holes are because I was too cheep to buy a virgin piece of steel.)   This is a much more elegant solution than hammer and chisel and never damaged a dog set or gear. Only recently have dog sets been available and some are of significantly lower quality than original. Being able to transfer dog sets paid for the tool X 10^3+. Best, Grady |

||

|

|

|

|

|

Registered

Join Date: Nov 2004

Location: Greater Metropolitan Nimrod, Oregun

Posts: 10,040

|

I was afraid it would be more $$ and effort to make a tool than to buy one... esp. since I can't weld (I tried to learn, but I got kicked out of welding class at Oregon State Univ. and had to take advanced multivariate statistics instead... no lie).

__________________

"A man with his priorities so far out of whack doesn't deserve such a fine automobile." - Ferris Bueller's Day Off |

||

|

|

|

|

Registered

Join Date: Dec 2003

Location: Arapahoe County, Colorado, USA

Posts: 9,032

|

Randy,

All you have to do is find a local quality machine shop and welder and have a statically significant number of P252s built. A t-test will tell. You can take data of the diameter and length and other dimensions. Assuming a normal distribution, you can apply linear discriminant analysis to see if the regression follows the general linear model or some other. This way you can sell the extras for profit with the knowledge that your statistics course was very significantly worthwhile with <1/100 outside the predicted confidence interval. Hehe. Best, Grady

__________________

ANSWER PRICE LIST (as seen in someone's shop) Answers - - - - - - - - - - - - - - - - $0.75 Answers (requiring thought) - - - - $1.25 Answers (correct) - - - - - - - - - - $12.50 |

||

|

|

|

|

Registered

Join Date: Nov 2004

Location: Greater Metropolitan Nimrod, Oregun

Posts: 10,040

|

cute - it was more on principal components & canonical correlation...

{also, I'm not as crazy as Island...} The OSU welding instructor must have seen my student info (graduate student in Zoology Dept.) -- he gave a speech about not wanting any filthy degenerate "hobbyists" in his class... continued to the effct that he was training "real welders" - that was in '74 -- I stil remember the words in quotes. It's OK - my hourly rate is just a tad more than most welders (Alaska pipeline; space shuttle; etc. excepted).

__________________

"A man with his priorities so far out of whack doesn't deserve such a fine automobile." - Ferris Bueller's Day Off |

||

|

|

|

|

Registered

Join Date: May 2000

Location: Los Alamos, NM, USA

Posts: 6,044

|

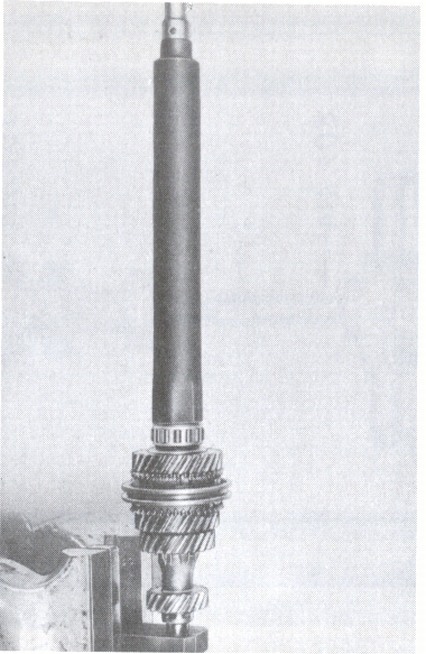

Okay, I'm told that the 914 engine and transmission have been dropped out of the car and my welding friend produced the below work piece (see image). As soon as I finish an on-going air conditioning project we will begin to work on the 901 transmission. I'm now seeking input on what diameter to bore out the original socket drive square to. I recall that the largest diameter on an input shaft before reaching the nut threads is the bell housing seal land. The comparable bore in the similar tool for the 915 transmission is .980" and lacking any other information I will have this one bored to the same diameter. Thanks.

|

||

|

|

|

|

Registered

Join Date: Dec 2003

Location: Arapahoe County, Colorado, USA

Posts: 9,032

|

Jim,

Yes the seal land is the largest diameter. It measures 22.00 mm. The clutch splines measure 20 mm. Best, Grady

__________________

ANSWER PRICE LIST (as seen in someone's shop) Answers - - - - - - - - - - - - - - - - $0.75 Answers (requiring thought) - - - - $1.25 Answers (correct) - - - - - - - - - - $12.50 |

||

|

|

|

|

Registered

Join Date: May 2000

Location: Los Alamos, NM, USA

Posts: 6,044

|

Great and thanks! Now its off to another friend who is a fair machinist and pretty good experimental physicist too.

|

||

|

|

|