|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: May 2002

Location: St Louis

Posts: 4,211

|

5.5 Volts

Is that a look up table with RPM on one axis and voltage on the other? The numbers for 2000 RPM do set the target current between 8 and 10 Amps (except 5 and 7 Volts)

__________________

Rick 88 Cab |

||

|

|

|

|

Registered

|

Rick, I keep coming back to the fact that maybe the specs we have for the coil may not be correct? Could be that coil is higher inductance than we think? Possible?

__________________

Sal 1984 911 Carrera Cab M491 (Factory Wide Body) 1975 911S Targa (SOLD) 1964 356SC (SOLD) 1987 Ford Mustang LX 5.0 Convertible |

||

|

|

|

|

Registered

Join Date: Feb 2014

Location: Lomita, CA

Posts: 2,709

|

Quote:

for the coil used in the 3.2/964! Design a simple test circuit using: a 3.2 coil, a 12V - 15A power supply, IGFET, current sense resistor, a clamp diode, a scope, and a pulse generator. Then using the following equation it's very simple: L (coil inductance) = V (coil voltage) X T (milliseconds) / I (coil current) The pulse time (T) is kept short to reduce the voltage effect of the primary resistance. The same circuit can be used to determine the coil's saturation current. Or just buy an RC meter, i.e. less $50. Using that you can calculate the secondary's inductance and the turns ratio.

__________________

Dave Last edited by mysocal911; 02-10-2016 at 08:43 PM.. |

||

|

|

|

|

Registered

Join Date: May 2002

Location: St Louis

Posts: 4,211

|

It isn't that simple if you want the peak current to go to 15 Amps. For me that is a bunch of capacitors.

I'll buy the inductance at 0 Amps is 3.6 and +/- 10% makes no difference.

__________________

Rick 88 Cab |

||

|

|

|

|

Registered

Join Date: Feb 2014

Location: Lomita, CA

Posts: 2,709

|

Good. Issue resolved. Thank you!

__________________

Dave |

||

|

|

|

|

Registered

|

Rick,

I think I crunched the dwell numbers incorrectly, this is what the dwell seems to work out to be from the dwell map at the 2000RPMs row: At 2000RPMs for these given voltages you have these dwell times: voltage : ms time : tooth count 5.5v : 7.2ms : 7.3v : 7.2ms 9.2v : 6.4ms 11.0v : 4.7ms 12.8v : 3.6ms 14.7v : 3.0ms 15.1v : 1.7ms (this is for any voltage above 15.1v) I calculated incorrectly when converting crank angle to time in ms. Do those dwell times line up better with your simulation?

__________________

Sal 1984 911 Carrera Cab M491 (Factory Wide Body) 1975 911S Targa (SOLD) 1964 356SC (SOLD) 1987 Ford Mustang LX 5.0 Convertible |

||

|

|

|

|

|

Registered

Join Date: May 2002

Location: St Louis

Posts: 4,211

|

Except for the low voltages those are almost exactly 8 Amps.

__________________

Rick 88 Cab |

||

|

|

|

|

Registered

Join Date: Feb 2014

Location: Lomita, CA

Posts: 2,709

|

Quote:

spark energy at about 12 -13 volts applied to the coil (+) terminal? Assuming that the dwell time is less than a value that results in the 8 amp current limit (just a little less than 8 amps) of the driver and L = 3.6 mH then: T = I X L / V = 8 X 3.6 / 12 = 2.4 ms (adequate dwell for adequate energy) E = 1/2 X L X I ^ 2 = 115 mjoules (30 - 50 mjoules considered minimum) So why the longer (3.6 ms) dwell time at 2000 RPM? Assuming L = 3.6 mH, 12 volts, 3.6 ms then: I = T X V / I = 3.6 X 12 / 3.6 = 12 amps ???? Where's the problem with the parameters, e.g. dwell = 2.4 or 3.6, or L = 3.6 or greater value?

__________________

Dave Last edited by mysocal911; 02-11-2016 at 08:37 AM.. |

||

|

|

|

|

Registered

|

Dave,

At 6000RPM the dwell map in the DME has the dwell at exactly 2.4ms for 13v And at 6400 it's at 2.25ms Just thought I'd share that. I agree with you that the coil inductance at 3.6mH does seem to line up with the what's in the dwell map. As I said my earlier dwell time calcs where wrong, I incorrectly converted crank angles to dwell in ms. EDIT: Keep in mind that the voltage in the dwell map is system voltage, at the coil the voltage will be lower. Some voltage is across the darlington and the 0.05ohm sensing resistors. I'm not sure how much voltage is across those components when we near the 8AMPs? Quote:

__________________

Sal 1984 911 Carrera Cab M491 (Factory Wide Body) 1975 911S Targa (SOLD) 1964 356SC (SOLD) 1987 Ford Mustang LX 5.0 Convertible Last edited by scarceller; 02-11-2016 at 08:47 AM.. |

||

|

|

|

|

Registered

Join Date: May 2002

Location: St Louis

Posts: 4,211

|

You have to take into account the resistance of the coil, sense resistor and Vce of the transistor. I aproximated it all at 0.8 Ohms

__________________

Rick 88 Cab |

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

Registered

Join Date: Feb 2014

Location: Lomita, CA

Posts: 2,709

|

Quote:

parameters of the ignition system without actually having to do a simulation or solve differential equations.

__________________

Dave |

||

|

|

|

|

Registered

Join Date: May 2002

Location: St Louis

Posts: 4,211

|

Through all this discussion we arrived at the fact that the DME coil is designed to operate very tightly at or slightly below 8 Amps based on the dwell times and electronics.

Of course I know you are going to say I knew this all along. This was most likely taken into account when the coil was designed for this and the 964 application (???). This goes back to the fact that this is a different coil from the MSD one and what that effects.

__________________

Rick 88 Cab |

||

|

|

|

|

Registered

Join Date: May 2002

Location: St Louis

Posts: 4,211

|

Putting the 8 mH 0.7 ohm coil in the circuit using Sal's numbers at 6000 RPM I get 3.3 Amps which works out to 43 mJ which is below minimum from what I've read.

__________________

Rick 88 Cab |

||

|

|

|

|

Registered

|

Rick, these thought exercises also help us better understand the Motronic system. For me it helps firm up my understanding of the code in the DME. I find these conversations most worth while, and if I ever want to try a different coil (or possibly maybe need to substitute another coil when the stock coils are no longer available) we could do that as well.

__________________

Sal 1984 911 Carrera Cab M491 (Factory Wide Body) 1975 911S Targa (SOLD) 1964 356SC (SOLD) 1987 Ford Mustang LX 5.0 Convertible |

||

|

|

|

|

Registered

|

Rick, and you would not have known that the MSD coil is borderline/marginal unless you know exactly what the DME does with dwell times.

So, in conclusion for this thread the answer seems to be: 'The MSD coil is NOT a proper substitute'.

__________________

Sal 1984 911 Carrera Cab M491 (Factory Wide Body) 1975 911S Targa (SOLD) 1964 356SC (SOLD) 1987 Ford Mustang LX 5.0 Convertible |

||

|

|

|

|

Registered

Join Date: May 2002

Location: St Louis

Posts: 4,211

|

Quote:

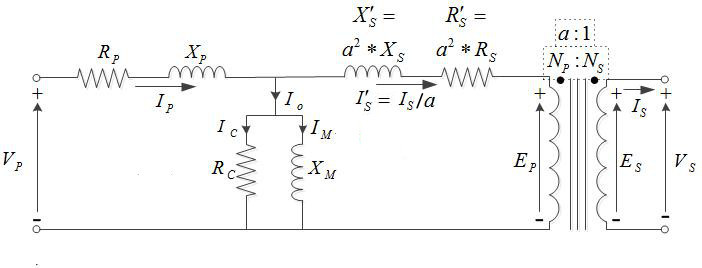

Rp effects the time to charge. The energy is stored in Xm. I don't think the secondary leakage (Xs) and secondary resistance (Rs) affect it much. wikipedia picture of a model

__________________

Rick 88 Cab |

||

|

|

|

|

Registered

Join Date: Feb 2014

Location: Lomita, CA

Posts: 2,709

|

Right, as was indicated way up-thread, e.g. post #18.

__________________

Dave |

||

|

|

|

|

Registered

|

Since the thread is about a possible aftermarket coil that may/could work properly, how about this one?

http://www.msdperformance.com/Products/Coils/Street/Strip/8253_-_HVC-2_Coil,_6_Series_Ignitions.aspx It's a 'HVC-2 Coil, 6 Series Ignitions' from MSD, looks very different but here's the specs: Turns ratio: 100:1 Primary resistance: .16 OHMs Secondary resistance: 630 OHMs Inductance: 3.5 mH Maximum voltage: 44,000 Volts Peak current: 450 mA Spark duration: 450 uS Weight: 3.75 lbs Not cheap, runs about $200! thoughts?

__________________

Sal 1984 911 Carrera Cab M491 (Factory Wide Body) 1975 911S Targa (SOLD) 1964 356SC (SOLD) 1987 Ford Mustang LX 5.0 Convertible |

||

|

|

|

|

Registered

Join Date: May 2002

Location: St Louis

Posts: 4,211

|

If I was going to spend $200 I would like to know the reasons why so I could weigh the trade offs, not just someones opinion since it seems to work fine. There originally was the question of would it hurt the DME.

Post #18 sounds like a recommendation for it. Quote:

__________________

Rick 88 Cab |

||

|

|

|

|

Registered

Join Date: Feb 2014

Location: Lomita, CA

Posts: 2,709

|

Quote:

Quote:

But if the MSD Blaster is really 4-4.5 mh versus the 3.2 coil at 3.6 mh, then the spark energy won't be significantly reduced as would be if the inductance were 8 mh. So then the MSD coil would not really be problematic in a 3.2 application. Again, it's all about the primary inductance, its series resistance, and the actual dwell time.

__________________

Dave Last edited by mysocal911; 02-11-2016 at 06:12 PM.. |

||

|

|

|