|

|

|

|

|

|

|

|

|

|

|

Registered

|

I would try running handmade harness wires for the sensor reading incorrectly back to the dme first to rule out any wiring problems. Whatever you do should include a full ground current return path from the sensor to the DME.

Everytime you pull the engine and disconnect the harness you risk damaging it further by breaking wires or cracking the insulation. At 30 years it is in a fairly delicate and baked state. The simplest way to gap the sensor is to glue a piece of cardboard of the correct thickness to the end and install it. The cardboard will wear away by itself. Credits to the board for this idea. Last edited by djnolan; 04-09-2017 at 01:28 PM.. |

||

|

|

|

|

Registered

|

|||

|

|

|

|

Registered

Join Date: Jun 2014

Location: Lake County, FL

Posts: 820

|

Quote:

My DME harness has virtually no risk of being damaged in such a manner because I fully removed it, replaced nearly all of the wires and connectors and reinsulated the entire thing. I have taken every oppertunity to rule out any electrical issues causing the symptoms I am recording. Correct. I did that.

__________________

PCA - Florida Citrus Region |

||

|

|

|

|

Registered

Join Date: Jun 2014

Location: Lake County, FL

Posts: 820

|

Today I pulled the bellhousing again and replaced the pin. The one I ordered from Porsche is stainless steel- I pulled a regular steel pin (you know, one that can be picked up by a magnet) and installed it. I set the speed sensor gap with a feeler gauge and put the bellhousing back together. No start.

I recently discovered that their are two different speed sensor shims. I purchased one that is around 2mm thick, and of course that caused the reference sensor to collide with the reference pin, BUT the car started and ran! I have figured out by chance that Porsche actually made a 2mm AND a 0.3mm shim. If I install the 0.3mm shim on the speed sensor, that will mean that my reference sensor will be .3mm closer to the reference pin and that might FINALLY be the ticket. Again, the oscilloscope is showing me a really weak signal on the reference sensor, a 0.5v peak. All of the grounds, sensor sheilds and wiring has been combed through very critically and I found absolutely nothing to be concerned about. So thats where I am at. If that doesnt work, who knows.

__________________

PCA - Florida Citrus Region |

||

|

|

|

|

Registered

Join Date: Jun 2014

Posts: 800

|

IMHO, I still think the wiring from the DME to the sensor plug should be replaced.

|

||

|

|

|

|

Registered

Join Date: Jun 2014

Location: Lake County, FL

Posts: 820

|

I did replace it, I replaced ALMOST every wire in the harness actually, I mentioned that alittle ways back.

__________________

PCA - Florida Citrus Region |

||

|

|

|

|

Registered

Join Date: Jun 2014

Posts: 800

|

I just biased because I have two 'recycleable' soybean harness cars in the yard. Even the cam in the headlight switch crumbles to cut down on that global warming thing.

|

||

|

|

|

|

Registered

Join Date: Jun 2014

Location: Lake County, FL

Posts: 820

|

No prob. I wish it was the harness... it would be running by now!

__________________

PCA - Florida Citrus Region |

||

|

|

|

|

Registered

Join Date: Jun 2014

Location: Lake County, FL

Posts: 820

|

UPDATE! So I pulled the engine so I could check the sensor alignment with feeler gauges and admittedly do some other work that needed to be done.

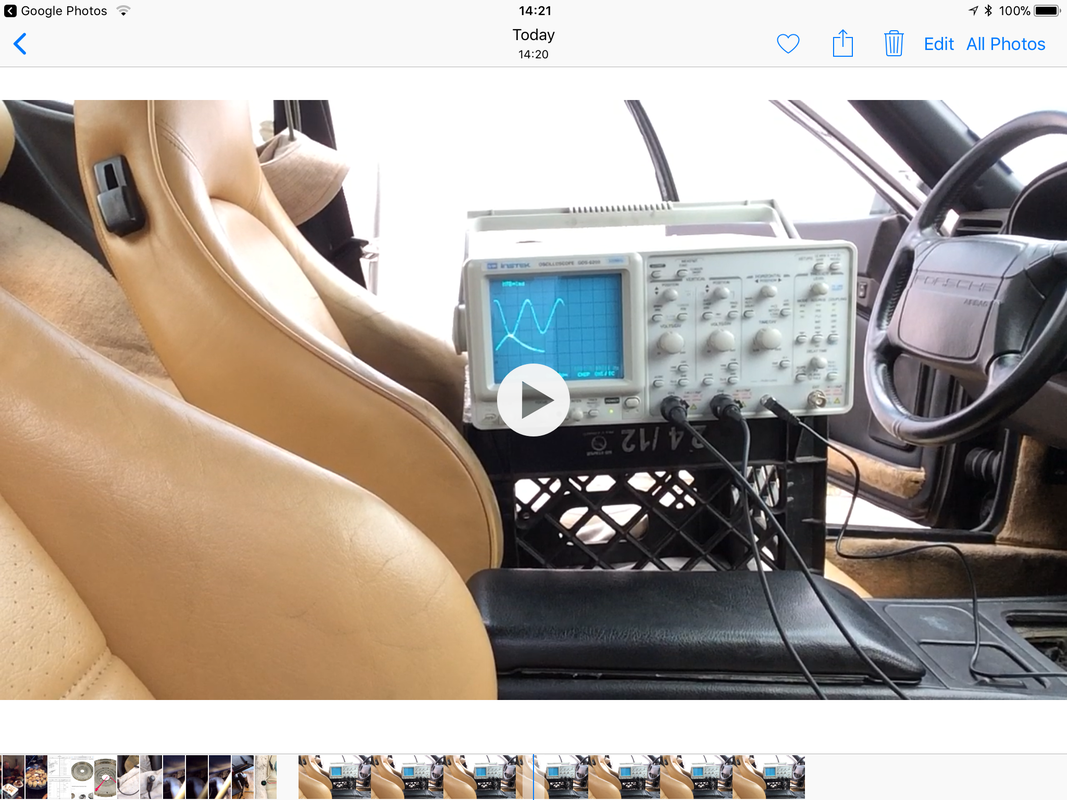

I added the 0.3mm shim to the speed sensor. For anyone reading this thread in research mode, there are actually two speed sensor shims- a 0.3mm and a much thicker one which I believe is something like 2mm. I set the speed sensor to be exactly 0.8mm with a feeler gauge. This put the distance of the reference sensor to the reference sensor pin at 0.24mm. If the 0.3mm shim wasn't used, the distance would actually be 0.54mm if the speed sensor was set properly. Before I started I showed a 0.2v positive flank on the reference sensor. When I reinstalled the engine with the new alignment and shim the reading is now ~6.0v (my oscilloscope only goes up to 5v). STRONG! The car starts and runs now. ISSUE RESOLVED!! Check out what I see on the oscilloscope for the reference sensor now, and compare it to the link provided earlier in this post- there is a 5.8v difference in amplitude for the reference signal and now its working. http://imgur.com/a/nDCk8 Soluton - added 0.3mm shim, realigned sensor bracket. strong signal, car runs.

__________________

PCA - Florida Citrus Region Last edited by Bradical; 06-03-2017 at 04:00 PM.. |

||

|

|

|

|

Registered User

Join Date: Apr 2018

Posts: 3

|

Thank you for providing this information and images of your oscilloscope.

I have a similar yet slightly different issue. Perhaps your experience can shed some light on what my next step could be. My car ran fine. I changed my clutch, and in the process I broke and replaced the reference sensors and bracket. The car will not start. The DME is not pulsing the fuel injectors nor the ignition coil. I have performed just about every test in the DME/KLR Test Plan; everything passes except Test Point #14 where I don't get a signal from KLR Pin 9. Attached is a screenshot of my speed / reference sensors video while cranking (Speed on top):  My reference pin is visible and I managed to measure 5mm depth (a very intimate experience through the TDC hole) I am using a used replacement bracket with the aluminum sleeve and new 2mm washer, appropriate for my car 1988 951 (indeed, the part number for that washer starts with "951 xxx ..." while the .3mm is "944 xxx ..." I have measured correct values at the DME harness for the both sensors (ohms). I managed to borrow a DME that apparently is good; it didn't make a difference. Oddly, my ignition coil's primary resistance measures *negative* .30. Thank you for any advice Last edited by Dan Martinic; 04-03-2018 at 06:42 AM.. |

||

|

|

|

|

In the Fires of Hell.....

|

There is a way to bypass the KLR for testing. I would do that and make sure that the car starts with your DME alone.

The KLR being bad can prevent your car from starting - I had mine go bad and had to replace it to make things good again.

__________________

PCA Instructor: '88 951S - with LBE, Guru chips, 3Bar FPR, 1.3mm shimmed WG, 3120 lbs, 256 RWHP, 15 psig boost |

||

|

|

|

|

Coeur d'Alene, Idaho

|

I am not an expert, having only had my 944 for 9 months. However, I have been through an experience that may shed light. I tested the harness values for both as good and went through the process you describe. Borrowed DME, etc.

After literally days of trying to figure it out, somehow we did not realize that though we tested both sensors and both harnesses, at some point my helper adjusted one of the sensors too close an it got whacked by the metal screw that protrudes out of the flywheel. From then on, that was the problem though we'd both waved our hands over the sensors as fine. It took us many days to restart the checklist and when we pulled the brand new sensors it was bent. So beware of assumptions you've checked something as these sensors can be damaged after you've checked. If too close, one sensor buzzes against the teeth. The other gets instantly broken/bent. I can't recall which is which but I think they're worth a look. Or a re-look.

__________________

84 944, 87 Vanagon, 88 Mitsubishi Van Wagon, 88 Supra Targa, 1990 Audi 90 20V Quattro sedan, 1992 Lexus LS400, 1993 LandCruiser, 1997 LandCruiser, 2017 Subaru Outback. |

||

|

|

|

|

|

Registered

|

I have an intermittent no-start on an 85.5 car. Sometimes I get a no-tach-bounce no-start condition. If I unplug the DME harness connector and reconnect it fires right up. I noticed a little moisture in the connector and I dried it and turned up the heater. Hope no-start doesn't return.

(the DME is laying on the carpet for easy access, due to some swapping of DME between AFM and MAF configurations and may be more susceptible to moisture?) |

||

|

|

|