|

Pre Registered

Join Date: Dec 1999

Location: Out of kindness, I suppose.

Posts: 1,826

|

An update from the consistently excellent Scarbf1's Blog:

China – Toro Rosso upright failure

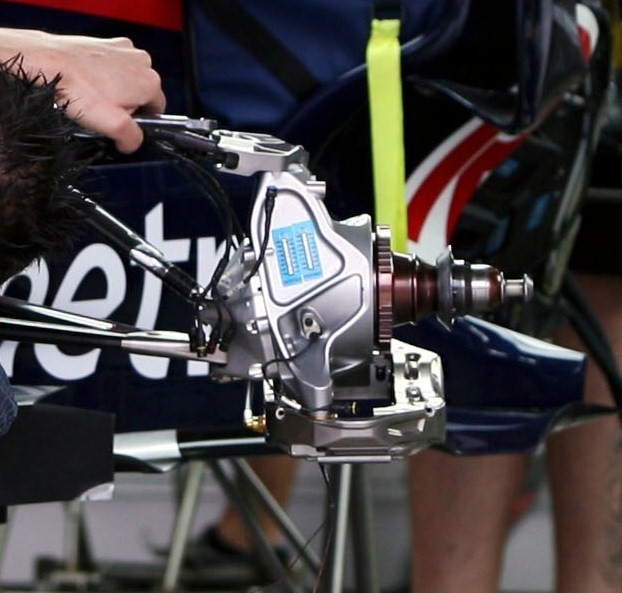

As you can see, the upright failed towards the top mounting (top right in this picture) where the top wishbone and steering arm connect.

In Free practice Friday, Toro Rosso suffered a massive front suspension failure. The team have put this down to the failure of the upright. An upright is the component that links the suspension wishbones to the axle and the wheel. It appears the upright was new and from a batch not previously used. Its not clear if the upright was a new specification or a newly manufactured batch of the existing spec.

Due the multitude of functions the upright has to accommodate, it is subject to enormous stress. This is particularly found under braking as the upright has both the load from downforce, braking and suspension movement. An upright is joined to the suspension at three places; the upper wishbone mounts via a spherical bearing\camber plate bolted to the top of the upright, the steering arm via a spherical joint\clevice bolted to the uprights front edge and the lower wishbone normally attached with a spherical joint bolted directly to the bottom of the upright. Then the brake caliper bolts to the upright in two places, lastly the axle (hub) rotates in two large diameter bearings through the middle of the upright.

A typical old format upright in cast titanium, featuring a vaned bearing holder:

Uprights were commonly made from titanium or MMC up until this year, when the rules were changed to demand aluminium. The BBC TV sports broadcast wrongly suggested they were made from carbon fibre, No Carbon upright has raced in F1. The metal upright is cast\machined, rather than the previous practice of welding various parts together, this is due to the different layout of the modern F1 upright, which no longer places the hub in relatively small bearings inside a vaned mounting to pass cooling air to the brakes. Instead the bearings are larger and the upright wrapped more tightly around the hub, the cooling air now passing around the upright via the carbon fibre brake duct. Only BAR\Honda had a different solution, which routed the cooling air inside an oversized hub to the brake disc. This set up compromised the packaging for the Brawn BGP001, leading to its relatively low nose. For 2010 Mercedes (nee Brawn) have more conventional uprights.

A BAR Honda Upright (exploded), with the large diameter hollow hub visible that feeds cooling air to the brake:

In Toro Rossos case the point at which the upright failed is yet to be confirmed, if it will be made public at all. Most likely the point at which suspension loads pass into the upright will be the area of highest stress and likely to cause the type of catastrophic failure we saw in Shanghai. Thus the failure could equally be attributed the wishbone ends or the camber plate, rather than the aluminium upright itself.

Tim

|

04-19-2010, 09:24 PM

04-19-2010, 09:24 PM

|

|