|

|

|

|

|

|

|

|

|

|

|

Registered

|

Now we know the real reason they've been having so many #3 drivers doing the 1st practice session!!!

__________________

2014 Cayman S (track rat w/GT4 suspension) 1979 930 (475 rwhp at 0.95 bar) |

||

|

|

|

|

Registered

Join Date: Feb 2000

Location: Dallas, TX

Posts: 4,614

|

Quote:

I agree with you in principle, but all that would mean is that the junior teams would be testing stuff for the main teams, e.g. Torro Rosso and Red Bull. They should allow unlimited Thursday testing to give the teams testing time and the circuit owners a chance to recoup their costs.

__________________

Neil '73 911S targa |

||

|

|

|

|

Make Bruins Great Again

|

I'm thinking that he was actually better off that both wheels ejected at the same time. Otherwise he might have made a hard right or left turn when one side dropped down.

__________________

-------------------------------------- Joe See Porsche run. Run, Porsche, Run: `87 911 Carrera |

||

|

|

|

|

Model Citizen

Join Date: May 2007

Location: The Voodoo Lounge

Posts: 19,338

|

Looks like the consensus is: TIME TO ALLOW SOME TESTING!!!!

F1 isn't some 8th grade science fair, the designers of these cars are brilliant and they have massive egos that don't let them contemplate the failure of their new ideas; computers cannot possibly simulate all the theoretical failures. TRACK TESTING OF ALL NEW COMPONENTS SHOULD BE REQUIRED. Just my 2 cents.

__________________

"I would be a tone-deaf heathen if I didn't call the engine astounding. If it had been invented solely to make noise, there would be shrines to it in Rome" |

||

|

|

|

|

Unregistered

Join Date: Aug 2000

Location: a wretched hive of scum and villainy

Posts: 55,652

|

How would you like to be a lucky fan who caught one of those free wheel souvenirs when it was going 150 mph?

|

||

|

|

|

|

Registered

|

|||

|

|

|

|

|

Motorsport Ninja Monkey

|

Quote:

You are correct that computers can't simulate every failure which is why most of the big teams have ways of making sure a part is fit for race and on track failures are very rare. Usually a safety critical part is created by the designer who will work with a FEA stress engineer to make sure the part will take the loads it's expected to see with certain safety factors. Depending on the load case safety factors can be as low as 1.1x the working load. Before the components are made there will be quality checks on the materials before anything has been machined or laminated. After machining every single component in a batch will be dimensionally inspected and non-destructive tested by either crack checking, real time x-raying etc and again the material spec will be tested. With laminated composite components these will be ultra-sonically, x-rayed, etc. Once the first of component has passed inspection it will be proof tested to a load that includes the safety factor. During this test a stiffness tolerance band will be created for each component for a set working load. After this the component will be fatigue tested to simulate track miles. Taking the example of the front suspension assy a mult-axis corner test rig will simulate 1000's of miles of different loads which would include braking, cornering, bump etc in a very short time span. Before the ban on in season testing all new component would have to complete a set amount of miles before it could be signed off for race use. Now with the ban on testing the reqirements for in house rig testing would be used as proof the component is fit for race. When a component is used on the track each individual one will have it's own unique serial number which will allow a record of the miles it has done to be recorded. These components will have a limited total racing life and a service life. During each service it will be tested on the rig to check it's stiffness is still with in the tolerance set during the proof test. They will also be dimensionally inspected again and non-destructive tested to check for any signs of damage. Hope this clears up your misconception

|

||

|

|

|

|

Model Citizen

Join Date: May 2007

Location: The Voodoo Lounge

Posts: 19,338

|

Quote:

I was just so flummoxed to see a failure of the type that Buemi encountered, that I went off half cocked (as usual!) and I want to offer my sincere thanks for shining some light on the process. I still like F1, but it has times when it just isn't as fun as it used to be.

__________________

"I would be a tone-deaf heathen if I didn't call the engine astounding. If it had been invented solely to make noise, there would be shrines to it in Rome" |

||

|

|

|

|

Registered

|

It took 30 min to put on a new front end........

.....and an hour to hose out the cockpit.

__________________

(As for) Michael Moore:Calling that lying liberal POS propaganda a documentary is like calling PARF the library of congress. I knew it would happen, just not so soon........... |

||

|

|

|

|

Senior Member

Join Date: Jun 2000

Location: N. Phoenix AZ USA

Posts: 28,977

|

Quote:

__________________

2021 Subaru Legacy, 2002 Dodge Ram 2500 Cummins (the workhorse), 1992 Jaguar XJ S-3 V-12 VDP (one of only 100 examples made), 1969 Jaguar XJ (been in the family since new), 1985 911 Targa backdated to 1973 RS specs with a 3.6 shoehorned in the back, 1959 Austin Healey Sprite (former SCCA H-Prod), 1995 BMW R1100RSL, 1971 & '72 BMW R75/5 "Toaster," Ural Tourist w/sidecar, 1949 Aeronca Sedan / QB |

||

|

|

|

|

Slackerous Maximus

Join Date: Apr 2005

Location: Columbus, OH

Posts: 18,232

|

If he's driving a Toyota, yes.

__________________

2022 Royal Enfield Interceptor 2012 Harley Davidson Road King 2014 Cayman S, PDK Mercedes E350 family truckster Steam locomotive. Yes, you read that right. |

||

|

|

|

|

Registered

Join Date: Nov 2000

Location: AZ

Posts: 8,414

|

Quote:

|

||

|

|

|

|

Senior Member

Join Date: Jun 2000

Location: N. Phoenix AZ USA

Posts: 28,977

|

Quote:

One woman sitting at a table far behind the fence got a free wheel when a car crashed. Unfortunately it killed her in the process...

__________________

2021 Subaru Legacy, 2002 Dodge Ram 2500 Cummins (the workhorse), 1992 Jaguar XJ S-3 V-12 VDP (one of only 100 examples made), 1969 Jaguar XJ (been in the family since new), 1985 911 Targa backdated to 1973 RS specs with a 3.6 shoehorned in the back, 1959 Austin Healey Sprite (former SCCA H-Prod), 1995 BMW R1100RSL, 1971 & '72 BMW R75/5 "Toaster," Ural Tourist w/sidecar, 1949 Aeronca Sedan / QB |

||

|

|

|

|

Pre Registered

Join Date: Dec 1999

Location: Out of kindness, I suppose.

Posts: 1,826

|

An update from the consistently excellent Scarbf1's Blog:

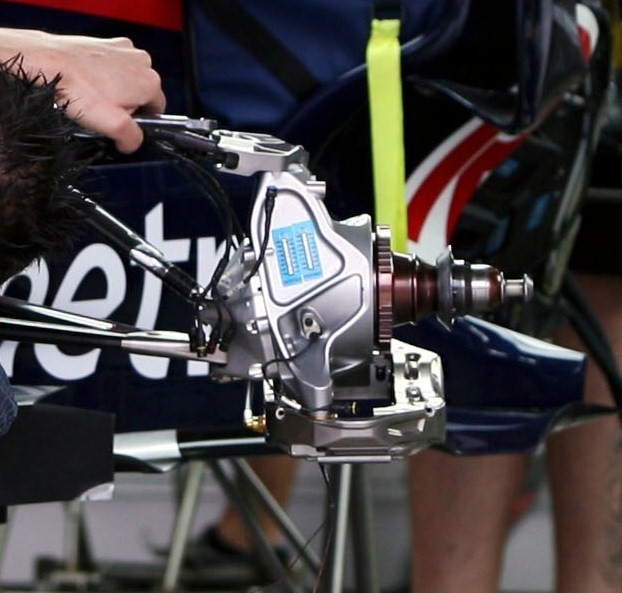

China – Toro Rosso upright failure As you can see, the upright failed towards the top mounting (top right in this picture) where the top wishbone and steering arm connect.   In Free practice Friday, Toro Rosso suffered a massive front suspension failure. The team have put this down to the failure of the upright. An upright is the component that links the suspension wishbones to the axle and the wheel. It appears the upright was new and from a batch not previously used. Its not clear if the upright was a new specification or a newly manufactured batch of the existing spec. Due the multitude of functions the upright has to accommodate, it is subject to enormous stress. This is particularly found under braking as the upright has both the load from downforce, braking and suspension movement. An upright is joined to the suspension at three places; the upper wishbone mounts via a spherical bearing\camber plate bolted to the top of the upright, the steering arm via a spherical joint\clevice bolted to the uprights front edge and the lower wishbone normally attached with a spherical joint bolted directly to the bottom of the upright. Then the brake caliper bolts to the upright in two places, lastly the axle (hub) rotates in two large diameter bearings through the middle of the upright. A typical old format upright in cast titanium, featuring a vaned bearing holder:  Uprights were commonly made from titanium or MMC up until this year, when the rules were changed to demand aluminium. The BBC TV sports broadcast wrongly suggested they were made from carbon fibre, No Carbon upright has raced in F1. The metal upright is cast\machined, rather than the previous practice of welding various parts together, this is due to the different layout of the modern F1 upright, which no longer places the hub in relatively small bearings inside a vaned mounting to pass cooling air to the brakes. Instead the bearings are larger and the upright wrapped more tightly around the hub, the cooling air now passing around the upright via the carbon fibre brake duct. Only BAR\Honda had a different solution, which routed the cooling air inside an oversized hub to the brake disc. This set up compromised the packaging for the Brawn BGP001, leading to its relatively low nose. For 2010 Mercedes (nee Brawn) have more conventional uprights. A BAR Honda Upright (exploded), with the large diameter hollow hub visible that feeds cooling air to the brake:  In Toro Rossos case the point at which the upright failed is yet to be confirmed, if it will be made public at all. Most likely the point at which suspension loads pass into the upright will be the area of highest stress and likely to cause the type of catastrophic failure we saw in Shanghai. Thus the failure could equally be attributed the wishbone ends or the camber plate, rather than the aluminium upright itself. Tim |

||

|

|

|