|

|

|

|

|

|

|

|

|

|

|

Fleabit peanut monkey

|

Quote:

Glad Packy is springing for new bolts. The more I think about it the more I am certain I did spring for new bolts in 99 when I had the trans re-done. May or may not have made a difference but given the coin I unloaded on the rebuild, flywheel re-face and Sachs Power Clutch package, I can't see myself saving a few bucks and re-using the old ones. The 101 projects book mentions nothing with respect to lubricant or anti-sieze. Neither does the Hayne's manual. I have the factory manual and Bruce Andersons book at home. So I can check. I am now confused, given absence of information, is clean and dry the norm for a street car? I would assume it is and I am pretty sure that is what I did. I have installed head bolts on cars where the instructions say clean with a touch of motor oil. All of the variants (oil, Blue Loctite, Moly) can tweak the torque settings a bit as tharbert says. However, on a street car, I bet dollars to doughnuts that if you torque them and the real value is between 60-70 ft pounds, given you torque them in the proper pattern, no risk. FWIW: I just dropped $1.29 on a single doughut the other day at the local mega marketer gas station. Renders "Dollars to doughnuts" expression obsolete.

__________________

1981 911SC Targa Last edited by Bob Kontak; 01-12-2016 at 02:54 PM.. |

||

|

|

|

|

Banned

Join Date: Nov 2007

Location: Rockwall, Texas

Posts: 8,559

|

Quote:

PS - it's amazing what ol' Sis Kontak can do with a sawsall, for sure! Last edited by Ronnie's.930; 01-12-2016 at 03:09 PM.. |

||

|

|

|

|

Schleprock

Join Date: Sep 2000

Location: Frankfort IL USA

Posts: 16,640

|

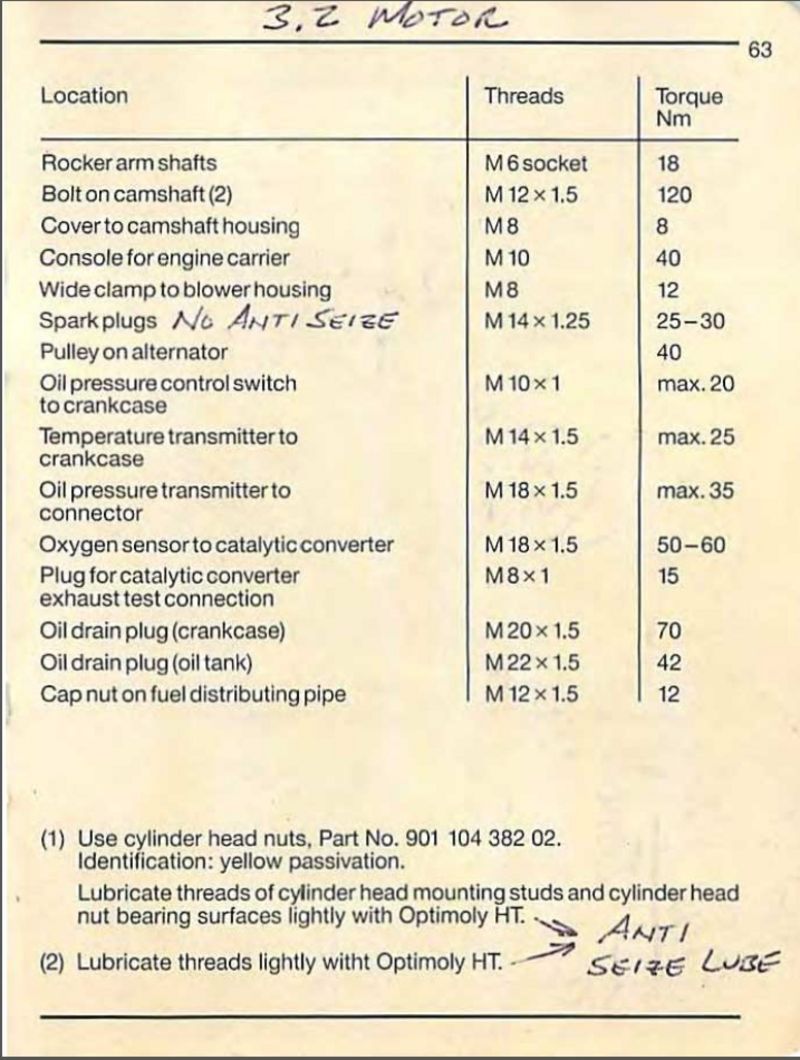

Factory spec is dry. Taken from '84-'88 technical spec book which mentions other fasteners like the head stud nuts and camshaft bolt using Optimoly HT (anti-seize paste)

__________________

Kevin L '86 Carrera "Larry" |

||

|

|

|

|

Fleabit peanut monkey

|

Outstanding. Just took a pic of my 3.0 spec book with my cell phone. Can't send it. Weather?

Says about the same thing. I will resend pic to my e-mail on the way home and post. If not. Tomorrow with a regular camera.

__________________

1981 911SC Targa |

||

|

|

|

|

Registered

|

When I was putting it all together I took my time going bolt to bolt opposite of each other creeping up past the torque spec. I got it out of Wayne's engine rebuilding book which I think states 66.3 ft-lbs. I used a little blue locktite, just a dab, and no moly. I was feeling uncomfortable with the moly.

Thanks for the help guys.

__________________

(1) '77 Chassis and '79 SC 3.0 project car (1) '79 911SC 3.0 Widebody SC (1) '15 Ford F-150 4x4 3.5TT Toluca Lake, CA |

||

|

|

|

|

Registered

Join Date: Dec 2002

Location: Long Beach, CA

Posts: 1,269

|

Factory manual, page E101, says to oil the threads of the bolts lightly and tighten them to 150 Nm. I think that all of the Porsche torque specs are for lightly oiled threads, unless otherwise specified. This is for an early, six-bolt flywheel.

|

||

|

|

|

|

|

Registered

Join Date: Feb 2004

Location: UK

Posts: 2,230

|

Quote:

Discussions about Torque to Yield fasteners (TTY) and Porsche engines continues to surface and in general this category of bolts doesn't seem to be very well understood. In recent Engine Builder magazine review of TTY fasteners by Mahle-Clevite there are several inaccurate statements which don't help. Basically TTY fasteners are tightened beyond their yield point and therefore deform permanently. There are two reasons for using fasteners in this manner. The first is when the clamping force needed for safe operation is greater than can be produced by an 'elastic' bolt. This used to be the case for the con rod bolts in early 2.0 litre engines but this changed when the rod was re-designed on the 2.2 litre engine. Mahle-Clevite suggest that when a bolt is stretched beyond its yield point it loses some of its elasticity - this just isn't true. Even the most basic examination of a material's tensile stress/strain curve will show that this statement is incorrect. The second reason is when nut runners are used and several fasteners are tightened at the same time. By reducing the initial torque and then tightening to an angle the preload in likely to be more uniform with less scatter which is a good think. I don't believe that Porsche flywheel bolts are TTY bolts and can be safely re-used unless they show signs of damage. If you always use new bolts then the scatter of preload will increase due to variation in thread surface finish. With regard to balance - I am not use small variations in the weight of lock wire will influence balance at the centre of the flywheel. The bolts, for example are not match weighed and will vary. I used to manufacture very high speed diaphragm couplings (100 000rpm +) and we used to critically match weigh bolts. |

||

|

|

|

|

Member 911 Anonymous

|

Thanks Brother Kevin!

You saved me a bit of dough   Quote:

__________________

'85 Carrera Targa Factory Marble Grey/Black * Turbo Tail * 930 Steering Wheel* Sport Seats * 17" Fuchs (r) * 3.4 * 964 Cams * 915 * LSD * Factory SS * Turbo Tie Rods * Bilsteins * Euro Pre-Muff * SW Chip on 4K DME * NGK * Sienes GSK * Targa Body Brace PCA/POC |

||

|

|

|

|

|

|

| Tags |

| crankshaft , flywheel bolt , safety-wire |