|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Apr 2008

Location: Miami

Posts: 963

|

Flow test- not getting enough fuel

I am completing a rebuild and putting a supercharger. Since the components are apart, I did a flow test on my CIS system. Here were the test conditions:

Equipment: Vehicle 79SC Bosch fuel distributor had the numbers O 438 100 031 WUR had the numbers O 438 140 042 which should match New CIS injectors with good spray pattern (these are 79SC injectors no electricity) Fuel is old ~ 1year but was stabilized from the beginning Fuel distributor had not been used for 1 year but was previously exercised, by connecting it to the CIS and cleaned through a FI cleaner until the system responded correctly (properly regulating system pressure) Test parameters: CIS by itself plumbed into the fuel system (engine is somewhere else in the garage) Current draw of the fuel pump during test: 10.4 A Voltage at the battery during test 12.22V System Pressure during test: 5.1 bar Temperature: 73F/23C (apologies to those up north) Test time: 1 min Procedure: Connect the CIS plumbing to the vehicle Put glasses underneath each injector Bleed the CIS gage Bleed the injectors until there is a good flow Push up on the air flow sensor plate control lever to maximum limit Simultaneously time the test WUR not in line (used CIS pressure measurement valve to cut off WUR) Results: All injectors flowed nearly identical amounts of fuel Measured fuel per injector was 150 ml Fuel had varying levels of turbidity: Cyl 1 clear, Cyl 2 some, Cyl 3 slight, Cyl 4-6 moderate (when the test was repeated, had Cyl 1, 2, and 4 clear and 3, 5, 6 some, with 6 being the worst in all cases) Conclusion: When placed into the formula: HP = (flow in ml/min * # injector)/(10.5 * BSFC) I get: (150 ml/min * 6)/(10.5 * .55) = 156 HP Way too low for SC and much too low for Supercharged system. Does anyone see any error in my procedure? Is there any other thing I should check? Below is an image of the fuel across all glasses (ignore the lines they were from a previous less formal test which motivated this test). The last glass contains water at the same level for measurement without ruining an extra glass:  Picture of the test setup:

__________________

1979 SC, Slant nose wide-body cab conversion. AEM Infinity EFI, COP, supercharged! Last edited by Dr J; 01-18-2010 at 03:44 PM.. |

||

|

|

|

|

Forced Induction Junkie

|

Quote:

These are Continuous Injection systems and deliver fuel 720* of the four-stroke cycle. I think that's where the error is and not in your measurements.

__________________

Dave '85 930 Factory Special Wishes Flachbau Werk I Zuffenhausen 3.3l/330BHP Engine with Sonderwunsch Cams, FabSpeed Headers, Kokeln IC, Twin Plugged Electromotive Crankfire, Tial Wastegate(0.8 Bar), K27 Hybrid Turbo, Ruf Twin-tip Muffler, Fikse FM-5's 8&10x17, 8:41 R&P |

||

|

|

|

|

Registered

Join Date: Apr 2008

Location: Miami

Posts: 963

|

Interesting point.

After thinking about it though, I believe it is accounted for. The equation does have provision for a duty cycle: HP = (flow * #injectors * duty cycle)/(10.5 * BSFC) In this case, the duty cycle of 100% becomes the number 1 (0.85 for 85%, 0.7 for 70%, etc.) Basically, the formula calculates the amount of fuel coming in (flow * # injectors * duty cycle) and converts it to HP, using a conversion factor (BSFC). The 10.5 converts the fuel from cc/min to lb/hr of gasoline.

__________________

1979 SC, Slant nose wide-body cab conversion. AEM Infinity EFI, COP, supercharged! |

||

|

|

|

|

Acceleration Junkie

|

Quote:

Measured injector output in 1-minute = 150ml. 150ml/min x6 inj = 900ml/min x 60 min = 54,000 ml/hr flow rate. 54,000 ml/hr = 14.27 gal/hr 14.27 gal/hr x 6.15 lbs/gal gasoline @68F = 87.76 lbs/hr burn rate Using the calculator at Connected Solutions - Fuel Injection Calculator and the values: 87.76 lbs/hr, 6-injectors, 0.55 BSCF yields 766HP with injectors at 80% duty cycle.

__________________

Chris Toy 356-930 Gone

|

||

|

|

|

|

Registered

Join Date: Apr 2008

Location: Miami

Posts: 963

|

Hello Chris

I think you accounted for the six injectors twice. The first time here: 150ml/min x6 inj = 900ml/min x 60 min = 54,000 ml/hr flow rate based on this you find a flow rate of 87.76 lbs/hr but that is for all 6 injectors not per injector. Then the second time here: 87.76 lbs/hr/injector, 6-injectors, 0.55 BSCF yields 766HP with injectors at 80% duty 150ml/min is 14.27 lbs/hr using the calculator on the website (since 1 ml = 1cc) If I multiply by 6 injectors I get 85.62 lbs/hr which is near your answer of 87.76 lbs/hr. If I use the calculator with the data: 14.27 lbs/hr, 6-injectors, 0.55 BSFC, I get 125 HP at 80% duty cycle. If I trick the calculator to 100% duty cycle by entering 14.27 /0.8 = 17.84 lbs/hr then I get: 156 HP, which matches my calculation. Still short...

__________________

1979 SC, Slant nose wide-body cab conversion. AEM Infinity EFI, COP, supercharged! Last edited by Dr J; 01-17-2010 at 01:14 PM.. |

||

|

|

|

|

Infidel

Join Date: May 2006

Location: UK

Posts: 1,172

|

Are the pumps getting plenty of power from the battery? Remember they'll have a lot of power when the car is actually running.

__________________

Jonathan. 87 930, 993 turbo engine, RS Tuning 520PS/515lbf-ft, Arrow Rods, ARP hardware, Solid lifters, G50-50, RS Flywheel, 890nm Sachs clutch, RSR coil overs all round, 993 C4 calipers front, 930 fronts on the rear, Ruf Speedlines..... Old 540 BMW, XB12S Modified, for being a total hooligan

|

||

|

|

|

|

|

Forced Induction Junkie

|

Jonathan,

Have you tried the calculator on your measurements you did with your 930? Or was that Stu's 930?

__________________

Dave '85 930 Factory Special Wishes Flachbau Werk I Zuffenhausen 3.3l/330BHP Engine with Sonderwunsch Cams, FabSpeed Headers, Kokeln IC, Twin Plugged Electromotive Crankfire, Tial Wastegate(0.8 Bar), K27 Hybrid Turbo, Ruf Twin-tip Muffler, Fikse FM-5's 8&10x17, 8:41 R&P |

||

|

|

|

|

Registered

Join Date: Sep 2006

Location: scotland

Posts: 248

|

It was my 964 turbo 3.3...I have since completed this test on several other 930's since then with all similar results in volume.

First of all you should be able to check your control pressure circuit flow rate to make sure all ok and within standard spec....Thats the fuel line that comes from the metering head to the wur..The 3.3 turbo for example should be 160-240 cm3/min....This volume should be able to be raised and i would check this first.

__________________

SP Autobahn www.spautobahn.co.uk Porsche inspector for Peter Morgan UK http://www.porscheinspections.com/ "92" 964 turbo,Modified and recently rebuilt using all ARP hardware.. Purpose built fuel controller set up to acheive perfect fuel curve on CIS inj. |

||

|

|

|

|

Infidel

Join Date: May 2006

Location: UK

Posts: 1,172

|

Hi Dave

Stu is the man the with the calculations really. The only time i've checked flow at all with my car was when we fitted the 993 engine, and wanted to know what the pumps would supply. The fuel pressure regulator at the time was 4.4bar (now 5.0bar), and it was delivering 144 ltrs an hour, or 1.2 ltrs every 30 seconds. I don't think that's any help, but that's the only calcs i've ever done with fuel

__________________

Jonathan. 87 930, 993 turbo engine, RS Tuning 520PS/515lbf-ft, Arrow Rods, ARP hardware, Solid lifters, G50-50, RS Flywheel, 890nm Sachs clutch, RSR coil overs all round, 993 C4 calipers front, 930 fronts on the rear, Ruf Speedlines..... Old 540 BMW, XB12S Modified, for being a total hooligan

|

||

|

|

|

|

Registered

Join Date: Sep 2006

Location: scotland

Posts: 248

|

Once you can confirm you have enough fuel on tap you could fit a wur from a turbo'd cis with the fuel enrichment feature...This would lower the control pressure somewhat more and may give you the fuel you need to keep your afr's in check now you have bolted a supercharger on there.

__________________

SP Autobahn www.spautobahn.co.uk Porsche inspector for Peter Morgan UK http://www.porscheinspections.com/ "92" 964 turbo,Modified and recently rebuilt using all ARP hardware.. Purpose built fuel controller set up to acheive perfect fuel curve on CIS inj. |

||

|

|

|

|

Registered

Join Date: Jan 2004

Location: Sacramento

Posts: 7,269

|

How much HP are you planning?

No CIS fuel distributor flows as much per cylinder than a 930 CIS fuel distributor except one from a Rolls. The 930 unit supports up to about 400fwhp max without modification. There is a fuel quantity & balance test here somewhere that states what the factory spec is for the 930. You might use that as a reference against you SC FD. If you are flowing 80% of what a 930 flows, that that would be about 300-320hp worth of fueling. I tried using math to figure out a 930 FD HP potential bit it did not add up for me either but I am not a math wizz. Also note that you are doing your test into an un-pressurized environment. On boost the added pressure will cut into your gross fuel delivery. |

||

|

|

|

|

Registered

Join Date: Apr 2008

Location: Miami

Posts: 963

|

Jonathan:

The battery was new and there was current draw. Actually, I noticed now that it was quite high at about 10 amps. Bentley says about half this and a test months ago showed 5 amps so I have to check this (I measured current at the battery not at the pump so it may include other equipment). When running, we may be at 14V or so, so about 20% more juice. Assuming we get 20% more fuel, still low, but I cant test all of this. Maybe I should also replace the fuel filter. Wonder if anyone has fuel flow rates post fuel filter. I got a few months ago 0.57 L/min A few months ago, I did a fuel flow test of the fuel from the pump before fuel accumulator and filter. I got 1 liter in 35 seconds (Bentley says 1 L per 30 sec so it's a little low) Stu: Glad you posted. Your meter head flow adjustment project inspired me to test my system. I hadn't thought about the control pressure circuit flow test. I will test and report. Maybe I'll repeat the test while keeping the WUR in the loop. Since I am pushing the plate by hand, the only effect is to allow flow through the WUR as opposed to my original test. Also, I had considered the turbo WUR. Any suggested vehicle year? 911st: Planning on 300 HP. This is the expected amount for a SOK whipple system. They don't say anything about modifiying the fuel system for the 3.0 engines (3.2 is a different story) so I expect there should be enough fuel in the stock system to handle it. BTW, if you are stuck on HP potential, I am pretty comfortable with the initial equation I provided (with the duty cycle addition). Also, the website calculator from Chris' post above is good. Any comments on the turbidity of the fuel? Yours looked all clear Stu.

__________________

1979 SC, Slant nose wide-body cab conversion. AEM Infinity EFI, COP, supercharged! Last edited by Dr J; 01-17-2010 at 08:36 PM.. |

||

|

|

|

|

|

Forced Induction Junkie

|

DrJ,

I won't be too concerned about the turbidity of the fuel. You did mention that you added a stabilizer over a year ago. Fuel will change in clarity over a period of time, getting cloudier, stabilizer will add to that effect as well. Can't explain why some cylinders are cloudier than others. Keep in mind the fuel is always being recirculated in the CIS systems. I would either drain the fuel tank and and use fresh fuel or use up the fuel you have but drive in a non-spirited manner. I would recommend a new fuel pump (maybe even a higher capacity?) and fuel filter once you start on your supercharging project. JBL930 has had very good luck with the Bosch 044 fuel pump.

__________________

Dave '85 930 Factory Special Wishes Flachbau Werk I Zuffenhausen 3.3l/330BHP Engine with Sonderwunsch Cams, FabSpeed Headers, Kokeln IC, Twin Plugged Electromotive Crankfire, Tial Wastegate(0.8 Bar), K27 Hybrid Turbo, Ruf Twin-tip Muffler, Fikse FM-5's 8&10x17, 8:41 R&P Last edited by WERK I; 01-18-2010 at 06:39 AM.. |

||

|

|

|

|

Infidel

Join Date: May 2006

Location: UK

Posts: 1,172

|

Both pumps on my 930 are new, i don't know whether they would produce less as they get old? I changed them as a precaution! I'm told i will run WAY out of injector before i'd run out of fuel with my set up, but then the CIS system is a higher pressure system than the 993, i think i'd be ok with my stock pumps even up to 600bhp? My fuel pressure is set at 5.0bar, the CIS system pressure can be shimmed up to around 7.0bar at the fuel head. That's a thought actually DrJ, at 5.1bar you're only at 74psi, a lot of guys on here are up at (and above) 100psi

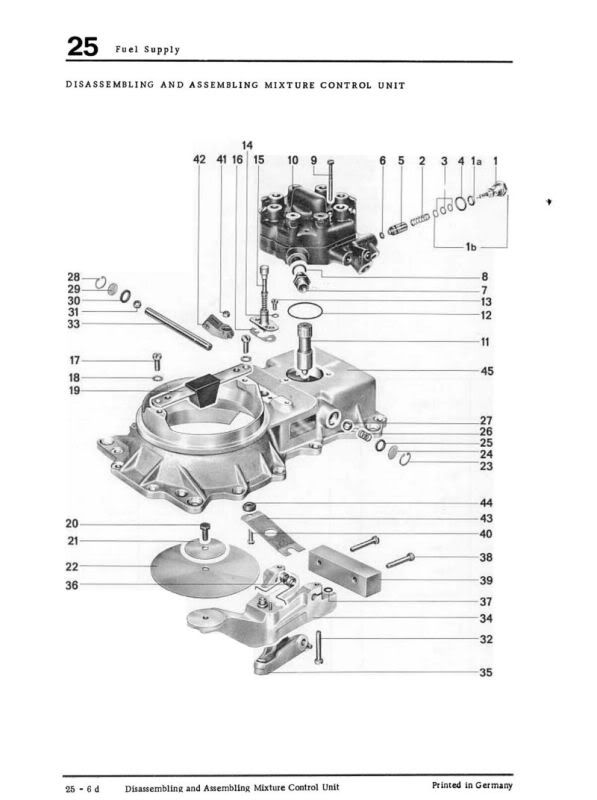

You can play with the shims in the fuel head, numbered 3 in this diagram  and get your system pressure cranked up!

__________________

Jonathan. 87 930, 993 turbo engine, RS Tuning 520PS/515lbf-ft, Arrow Rods, ARP hardware, Solid lifters, G50-50, RS Flywheel, 890nm Sachs clutch, RSR coil overs all round, 993 C4 calipers front, 930 fronts on the rear, Ruf Speedlines..... Old 540 BMW, XB12S Modified, for being a total hooligan

|

||

|

|

|

|

Forced Induction Junkie

|

Quote:

__________________

Dave '85 930 Factory Special Wishes Flachbau Werk I Zuffenhausen 3.3l/330BHP Engine with Sonderwunsch Cams, FabSpeed Headers, Kokeln IC, Twin Plugged Electromotive Crankfire, Tial Wastegate(0.8 Bar), K27 Hybrid Turbo, Ruf Twin-tip Muffler, Fikse FM-5's 8&10x17, 8:41 R&P |

||

|

|

|

|

Forced Induction Junkie

|

I was able to find a Bosch Fuel Pump Spec Sheet, if anyone is interested.

__________________

Dave '85 930 Factory Special Wishes Flachbau Werk I Zuffenhausen 3.3l/330BHP Engine with Sonderwunsch Cams, FabSpeed Headers, Kokeln IC, Twin Plugged Electromotive Crankfire, Tial Wastegate(0.8 Bar), K27 Hybrid Turbo, Ruf Twin-tip Muffler, Fikse FM-5's 8&10x17, 8:41 R&P |

||

|

|

|

|

Registered

Join Date: Jan 2004

Location: Sacramento

Posts: 7,269

|

Great info Dave.

If it has not been said, I think the SC has one pump, a 930 two. One way to get more fuel is to increase the system pressure at the FD but shimming the regulator where the fuel exits. However, you have to have a pump that will support this. Another way to potentially increase system pressure and fueling is to put a raising rate fuel pressure reg on the FD exit and plumb the WUR discharge to the exit of the RRFPR. This would give you on boost enrichment without having to change the WUR and enrichment might be a more a function of how much boost your run. Just a thought. |

||

|

|

|

|

Registered

Join Date: Apr 2008

Location: Miami

Posts: 963

|

Did a bunch more tests and I found the following:

Pump current draw is 9.5 A Replaced fuel filter: This gave a higher pressure (about 0.3 bar) I took the FD return line to the fuel tank and put a container and repeated the test. Again the injectors flowed about the same 150-160 ml per injector with the same amount in all cylinders. This time there was no turbidity in any of the gas. The FD return to the tank dumped 1.8L in the one minute test. This tells me that there is plenty of gas coming in but it is being dumped right back into the fuel tank rather than going to the injectors. For this test, the WUR was connected and at 3 bar control pressure. Wouldn't changing the pump just dump more fuel back? Since this is an SC FD with the plastic hoses, how much more CIS fuel pressure can it support? BTW, there is only one fuel pump on the 911 SC

__________________

1979 SC, Slant nose wide-body cab conversion. AEM Infinity EFI, COP, supercharged! |

||

|

|

|

|

Registered

Join Date: Apr 2008

Location: Miami

Posts: 963

|

Found this from boyt911SC in this link: 81 911 Cis-k Test Questions

"Someone has suggested doing the flowrate measurement using the 6 injectors. This procedure will tell you the flow rate via the FD (fuel distributor) and the value of the flowrate obtained is no where close to the fuel pump delivery rate. WHY? A portion of fuel delivered by the FP is diverted back to the tank via the FD pressure release valve. Since a good FP can deliver excess fuel needed by a CIS, the excess fuel is directed back to the gas tank. Any more questions? Just ask. Good luck. Tony" I found Rob (1980SC) doing the flow test and ending up with 41 oz/min (total of 6 injectors) in this link: CIS Gurus - Help me Safely Inject my Hot Rod 3.0 This is 202 ml/min per injector on a 78-79 FD at roughly 5 bar. In this thread, Souk posts that others have 7.4 oz/min for a 3.2: What are early 3.0L injector flow rates? This is about 220 ml/min

__________________

1979 SC, Slant nose wide-body cab conversion. AEM Infinity EFI, COP, supercharged! Last edited by Dr J; 01-20-2010 at 07:31 PM.. |

||

|

|

|

|

Forced Induction Junkie

|

The return line on fuel injected engines allows the fuel to cool. This is necessary because the pressures in these types of engines create unwanted heat.

When fuel pumps wear, the rated fuel pressure may drop off when the highest demands (Max. HP) are placed on the engine. If the injector output is within factory specs at maximum demand, then you may be ok. If you plan on elevating fuel pressures to get higher injector output, a different pump may be in order. If you have the type of Bosch pump in use, check the specs to make sure it is capable of delivering the fuel requirements for a 300HP engine.

__________________

Dave '85 930 Factory Special Wishes Flachbau Werk I Zuffenhausen 3.3l/330BHP Engine with Sonderwunsch Cams, FabSpeed Headers, Kokeln IC, Twin Plugged Electromotive Crankfire, Tial Wastegate(0.8 Bar), K27 Hybrid Turbo, Ruf Twin-tip Muffler, Fikse FM-5's 8&10x17, 8:41 R&P |

||

|

|

|

|

|

|

| Tags |

| cis , flow test , fuel distributor , injection |