|

|

|

|

|

|

|

|

|

|

|

Counterclockwise?

|

Wow. This will not be an everyday engine they are building for you Jeff.

__________________

Rod 1986 Carrera 2001 996TT A bunch of stuff with spark plugs |

||

|

|

|

|

Registered

Join Date: Aug 2014

Location: Sydney, Australia

Posts: 596

|

|||

|

|

|

|

Registered

Join Date: May 2004

Posts: 889

|

Quote:

All parts we are doing for Jeff will be available to all. Nothing will cost more than what is already available, I think?? Until we get everything in hand we cannot be certain however. But it is the intention to offer something comparable cost wise but more modern. Much of the work we have completed was bringing the parts back to health, not any customizing. The case work is all typical except for the through dowels. These we have decided to use the through bolt holes and keep the extra rigidity closer to the housing bore. There are a few oil galley holes we have to consider but these are very small as they feed the Piston oiling valves only. This is a minor consideration. The crank is stock and no lightening or counterweight "knife edging" will be done. This is something that should never be done to these cranks. The Oil pump is getting new scavenge gears that be more efficient as well as help with oil cooling. These will be available to all and will only require swapping out the stock spur gears. The rods have been stretched by an offset pin bushing. The pin size has dropped down to something more realistic for a 200 - 275 HP engine allowing this to happen. This is a mod than any stock rod can have done without buying aftermarket rods. The rods will be top guided to help keep the Pistons straighter in the cylinders. The Pistons are new to suit the stretched rods and these will sell for approx the same as stock replacements. The intention is to change the design and make them more modern using a stiffer forging. The top guided rod will allow a thinner ring pack and a little less tension. Cylinder Heads are stock basically. We did open up the ports only to match the Intake manifolds Jeff will use and the Exhaust he has repaired. The seat shapes are new and we have done quite a bit of work on them. Most Porsche heads will have new guides fitted over their lifetime. The problem with fitting new guides to these heads is holding the concentrically with the existing seat. The hemi chamber is the biggest cause here. The guides never go in perfectly concentric. The seats often have already being cut. Now you have to re cut the seat angles even lower to obtain the seats concentric to the new Guides. This is why you see the chambers cut as well to obtain some sort of top angle transition to the chamber. There really is no way around this other than new seats which cost way more to do. So we have designed a new seat shape that lowers the amount the seats have to be cut and how much the chambers have to be cut when doing this work. The added benefit was some increase in flow as well especially at low lifts. The cost to do this is no more than the std seat work. Valve are all stock. Springs are new but more attention is being had on the set up. Most of the heads we have ever seen here are well over sprung and HP is lost in just turning the engine round and round. Top Retainers will remain steel as Titanium or Aluminium Retainers should never be used in any engine unless it comes apart on a regular basis. Camshafts are new but the cost to regrind will be the same. The rest is new and will be available to all if wanted. Jeff has decided to go EFI, so we will put together a simple kit for him made up of parts we consider to be equal to the task. We will not be creating a system that is capable to going to the moon and back. That's not the idea. If it gives others an idea of what is OK and clears up any confusion, then we have successfully done what we set out to do. There are many really good choices to be had, this will be what we consider to be one of them. Hope this clears up what we are trying to do here. |

||

|

|

|

|

I would rather be driving

Join Date: Apr 2000

Location: Austin, TX

Posts: 9,108

|

Pelican has EFI adapters if you want to use MFI stacks.

Yes, I make these and sell through our hose.

__________________

Jamie - I can explain it to you. But I can not understand it for you. 71 911T SWT - Sun and Fun Mobile 72 911T project car. "Minne" - A tangy version of tangerine #projectminne classicautowerks.com - EFI conversion parts and suspension setups. IG Classicautowerks |

||

|

|

|

|

Registered

Join Date: Aug 2014

Location: Sydney, Australia

Posts: 596

|

I already have TWM ITB's for the engine.

__________________

See my 2.8RSR build on YouTube 'Home Built by Jeff' http://youtube.com/homebuiltbyjeff http://forums.pelicanparts.com/porsche-911-technical-forum/889676-home-built-hot-rod.html#post8868732 |

||

|

|

|

|

I would rather be driving

Join Date: Apr 2000

Location: Austin, TX

Posts: 9,108

|

Then you are good to go. I have used them on many builds. They work well.

A word of advice. The TWM/Borla ITBs have a hokey (IMO) vacuum port that connects the throats with a single, large output. You will not get a good MAP reading from this port. You will need to close this port internal to the ITB with epoxy (finish appropriately) and add additional vacuum lines below the throttle - one to each throat. I usually install hose barbs in the manifolds then bring 6 throats into a vacuum manifold before going to the ECU/MAP sensor. You will have a much more stable vacuum signal - especially at lower rpms where cam reversion can wreak havoc with your sensor and idle quality.

__________________

Jamie - I can explain it to you. But I can not understand it for you. 71 911T SWT - Sun and Fun Mobile 72 911T project car. "Minne" - A tangy version of tangerine #projectminne classicautowerks.com - EFI conversion parts and suspension setups. IG Classicautowerks |

||

|

|

|

|

|

Registered

Join Date: Aug 2014

Location: Sydney, Australia

Posts: 596

|

That sounds like a good tip and makes sense. I will look into that.

__________________

See my 2.8RSR build on YouTube 'Home Built by Jeff' http://youtube.com/homebuiltbyjeff http://forums.pelicanparts.com/porsche-911-technical-forum/889676-home-built-hot-rod.html#post8868732 |

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 889

|

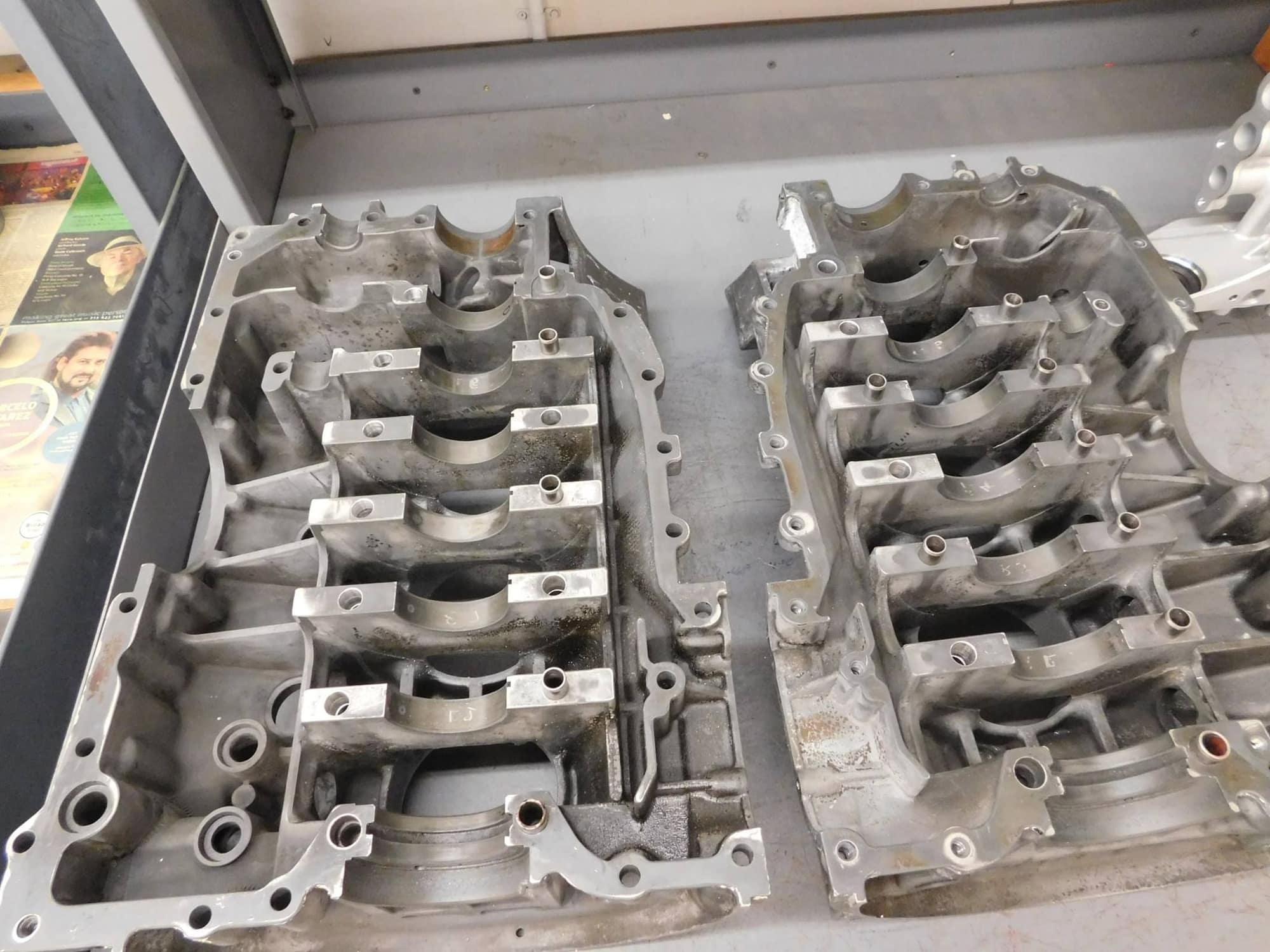

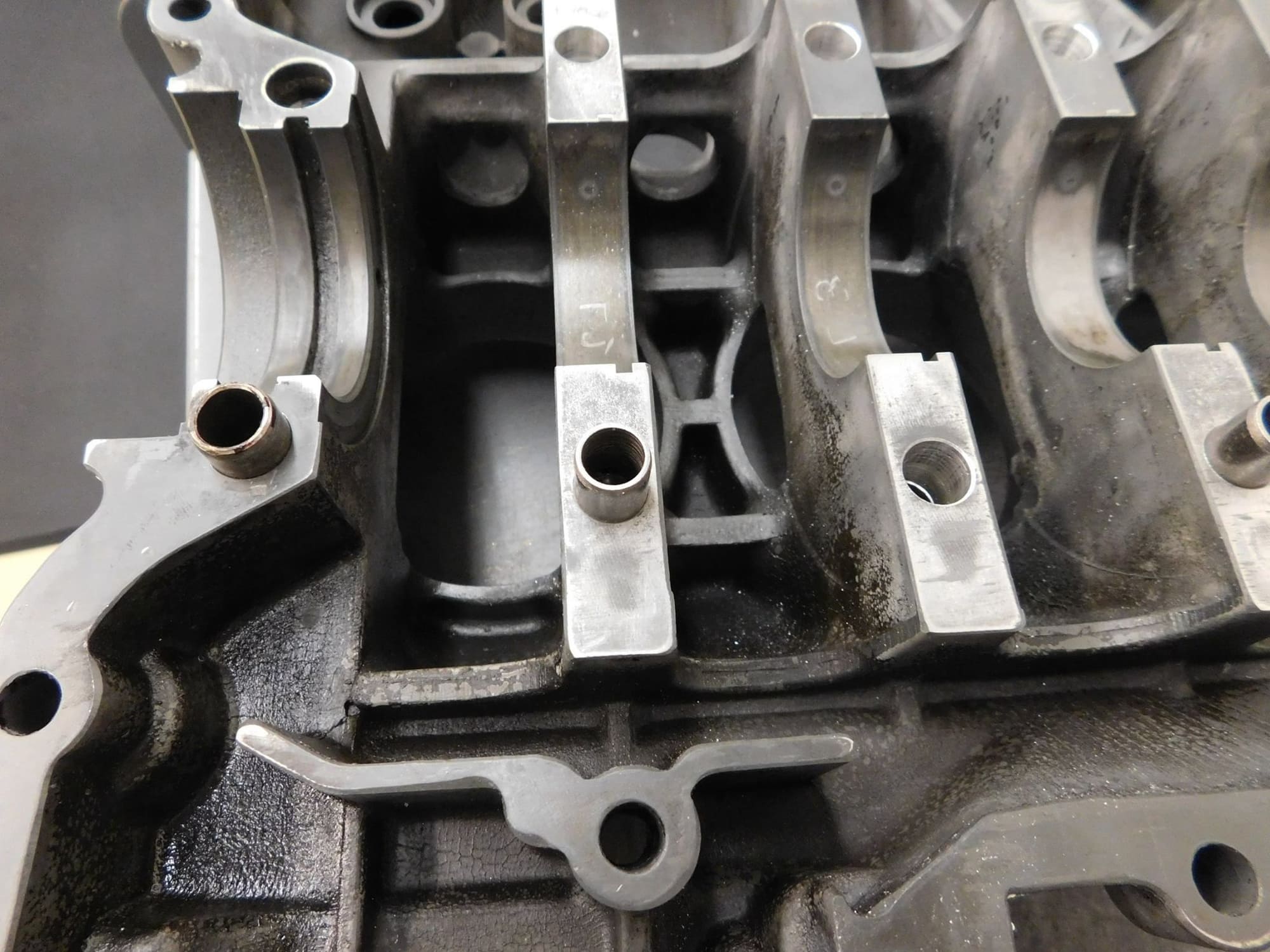

I thought I would bring this project up to date with where we are on Jeff’s project.

We have slowed down some lately as we are awaiting the new Pistons from Mahle. This has given us some down time to get on with other projects. All the non-typical repair work (the saving part) is completed and a lot of the typical machine repair work is finished. The case has the new dowels fitted and together. The crankshaft is reconditioned and now we can continue with the main bearing saga. The rods are semi complete, new fasteners, sized BE, offset bushing fitted and bored, now waiting for the new piston pins to hone for clearance. Then we will taper the small ends and balance. Pistons designed and in production. This is a new design moving away from the normal piston produced currently for these early 911 engines. Custom, yes but it will be available for anyone in the future. Cylinders are out for re plating. The heads are semi-finished and we expect these to be completed this week. New guides have been fitted along with new seat inserts. The ports have been matched for the new Intake manifolds and the exhaust system Jeff is going to use. Three heads were set out to have the exhaust studs burnt out. They are expected back here this coming week and the final seat work will be done. A completely new Cam design has been created and will be sent out to be cut on new blanks in the coming weeks. This new design is a complete departure from what has commonly being offered for these engines. The rest of the parts have either been completed or yet to be started. This project has rekindled our enthusiasm for the early 911 air cooled engines. We will offer machine repairs and a build service to anyone who would like this, but we are realistic in knowing that our costs are above what most are prepared to pay. I have taken to reading the posts on this forum by many DIY owners and understand there is still a lot of trepidation in rebuilding these engines. They may be simple to us but to many they instill fear and uncertainty. I have written some papers that will be up on our web site shortly and intend to write more including a complete series on rebuilding these engines. These will uncover any un necessary mysteries on the machine work and give a guide on how we rebuild these engines. Written by someone who does the machine repair and rebuilds these engines for a living, our advice, and explanations on “how to” may give more confidence to the DIY than what is currently available. I will include many of the tricks that we have developed over the years along with shortcuts and explanations on why certain procedures are important. I decided to write these papers as the DIY is going to rebuild his or her engine regardless of what services I or my peers make available. Why not give advice on how it should be done and help remove some of the fear? I have great respect for a few of my peers, particularly how they operate their businesses. Quality first, with honestly and integrity, so I will be very respectful of that in what I write. |

||

|

|

|

|

Registered

Join Date: Jun 2013

Posts: 491

|

Neil,

I very much look forward to reading your "how to" guides and appreciate the effort you have invested in producing them. |

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 889

|

Jeff's project got us excited about this work again.

I'm happy to share how we do this work and if anyone gains any knowledge and inspiration, then we have contributed. The Cylinder head paper is up on our web site and over the next few weeks we will put up further papers about rebuilding these engines. |

||

|

|

|

|

Registered

Join Date: Aug 2014

Location: Sydney, Australia

Posts: 596

|

Neil at performancedevelopments.com has been very busy working on my nightmare nightmare engine. He has now finished the work on the case. After repairing all of the pulled and mangled studs, he has gone through and added dowels. Many will just add dowels in the journal face next to the through bolt holes, but Neil actually puts sleeves into the through bolt holes.

The crankshaft has been magnufluxed, staightened, and the oil plugs removed and threaded for plugs.   The cylinder heads have been repaired and twin plugged. New valve guides have been fitted and new valve seats have been made and fitted with multiple angled bevels for better flow. Neil also found that after fitting the new valve guide on one of the heads, it was cracked on the edge of the guide housing. Again, instead of just throwing the head away, the crack was re-welded and repaired.   New Cams have been designed. Neil is now working through the Cam decks, working out a better method to prevent leaks from the bores. I will post up the pictures when it is done to show the results. Many of you have been asking me what is happening with the engine and Neil is putting in a crazy amount of hours on this. Particularly on developing new, upgraded, methods of repair and improving on the almost 50 year old design of these engines. If you have any detailed questions head over to Performancedevelopments.com and talk to Neil, as most of this is way over my head.

__________________

See my 2.8RSR build on YouTube 'Home Built by Jeff' http://youtube.com/homebuiltbyjeff http://forums.pelicanparts.com/porsche-911-technical-forum/889676-home-built-hot-rod.html#post8868732 Last edited by MFX; 10-11-2017 at 07:09 PM.. |

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 889

|

We are close to getting Jeff's parts back into a usable condition. I owe updates on how and what we have done, and will get to this as son as I can. I know its interesting to many, so I will do my best to get this done.

This project turned into a huge task once we unpacked the parts. It became immediately clear what we had to do. The case has some serious issues as did the Cylinder heads. The pictures Jeff posted show some of the work we have completed but most of the work to date is unseen as it was all about bringing this engine back into just repairable condition. The case is finished, (I think), the head need the sealing ring grooves machined, and then assembled. The rods need the pin bores honed for pin clearance once we have the new pins in house. The cam decks are in progress, but this requires us to make a boring bar to bore the pin bores oversize then fit inserts and final hone to size. A lot of work still to do, and I will get a more comprehensive and detailed report on this engine project with more photos up on our web site ASAP. nh |

||

|

|

|

|

|

Registered

Join Date: Jul 2013

Location: Brisbane, Australia.

Posts: 2,674

|

So what is the 'saga' relating to the main bearings?

|

||

|

|

|

|

Registered

Join Date: Aug 2014

Location: Sydney, Australia

Posts: 596

|

I can't remember where that was mentioned, but the issue we had was that both the case and the crank were undersize. Getting 1 over on either is reasonably common, and reasonably affordable, but getting bearings 1 over top and bottom, I believe is very expensive. That is my understanding anyway.

__________________

See my 2.8RSR build on YouTube 'Home Built by Jeff' http://youtube.com/homebuiltbyjeff http://forums.pelicanparts.com/porsche-911-technical-forum/889676-home-built-hot-rod.html#post8868732 |

||

|

|

|

|

Registered

Join Date: Aug 2014

Location: Sydney, Australia

Posts: 596

|

So it has bee quiet for a while waiting for the new design pistons to come in Mahle. Neil has designed them to a more modern spec, with shorter skirt and set up for the 18mm pin, lightening them from the original 22mm pin. They look fantastic!

Now we have some big movement planned. I am heading back over to LA from the 10th to the 16th of June to finish things off. That hopefully includes the last of the machining, building the wiring harness and assembling the bottom end. I also plan on doing daily videos while I am there to keep you guys up to date with the step by step progress. While I am over there, Neil is looking at running an extensive air-cooled engine building workshop covering some of the machine work involved, proper assembly, etc. He wants to keep it to just 2 guys, so if you are interested you should contact him at Performance Developments for more details. He has a lifetime of experience building engines for F1, Andial, and so much more, and his knowledge is amazing and I think it would be well worthwhile. Also while I am over there, I am keen to catch up with some of you guys on the evening of Friday the 15th somewhere in Orange County to be nominated. https://photos.app.goo.gl/rNdTpGhssU6MGanP2 https://photos.app.goo.gl/rNdTpGhssU6MGanP2 https://photos.app.goo.gl/Ng4oGfQfUZyes7j32 https://photos.app.goo.gl/HJuv3oEPOt6E1FDk2 Rockers have also been resurfaced and hardened. [IMG]ttps://photos.app.goo.gl/H2yoxKex29rkKJBn2[/IMG]

__________________

See my 2.8RSR build on YouTube 'Home Built by Jeff' http://youtube.com/homebuiltbyjeff http://forums.pelicanparts.com/porsche-911-technical-forum/889676-home-built-hot-rod.html#post8868732 Last edited by MFX; 05-14-2018 at 05:42 PM.. |

||

|

|

|

|

Registered

Join Date: Nov 2004

Location: calgary.ab.ca

Posts: 252

|

Awesome Jeff. I may have fondled your pistons - they are a thing of beauty. I Was in to see Neil when there for Lit Show to drop off my case. He should be finished with my case next week so I can tackle my assembly over the summer/fall.

I look forward to your videos - I'll be studying them as I get ready to assemble mine!

__________________

Keith - Calgary 1969 912R (911 engine) - Blutorange |

||

|

|

|

|

Registered

Join Date: Jul 2005

Location: Atlanta

Posts: 1,241

|

I guess what I don't understand was the need to re-engineer components which have been tried and true for ages. Rocker shafts, pistons, camshafts, there are several good options out for the latter two, and with rocker shaft seals I don't get why it's necessary to reinvent the wheel there. Not trying to rain on the situation, but it puzzles me.

__________________

No physical quantity completely explains its own existence |

||

|

|

|

|

Registered

Join Date: Sep 2015

Location: Costa Rica and Pennsylvania U.S.

Posts: 3,301

|

sleeves

We have been using sleeves in the through bolt holes since the late 70s here in the east coast.I have a local machinist who has done this service for 40 years in NJ.Great resurrection of this motor by Neil Harvey.Fred

|

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 889

|

We have not re engineered a lot of the parts because the earlier versions failed. A great many of these early engines use the same pistons and other engine components designed back in the 70's with great success.

We are a performance business and our core business is to offer parts and services above that of the production types. We design and have made many parts that may not produce power by their design, but gain back performance lost in simply the running of the engine. These are the parasitic losses well known to many. For example, lowering weight, running tighter clearances, holding the piston straighter in the bore at high piston speeds all are details not considered back in the 70's compared to today. Computer design and analysis have helped us hugely here. Its not for all and the older designs certainly do a great job as proven in many engines. We are just offering an newer alternative that will net some gains in performance at the same time. We have used Jeff's engine to develop these parts along with some newer techniques we have not ever done before. Everything in life moves on. We have the first set of the "new" head studs in house, developed for the 911 engine that include fixes for many of the inherent problems still encountered by many with existing stock and aftermarket studs. New material, new design and some features in the associated hardware are included in these new kits. We have spent a lot of time conducting laboratory testing on many of the different studs available, different greases and different tightening procedures. Clamping loads along with many other measurement have all being documented and these will be available once the parts become available. We have heavily concentrated on the actual application and installation needs here as well. I'm am currently rewriting the procedures and installation methods we recommend when using these new studs. Jeff is coming here mid June and more info will be made available then. I love these early air cooled engine for their simplicity. But there are many areas that can be made more efficient and this is our focus. |

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 889

|

Getting real close finishing Jeff's engine. We have done so much that typically would not be done. In most rebuilds, new or good used parts would have been purchased. We used this project and what we did to help Jeff, and to show what we can do.

We stopped building these 911 engines many years ago. Jeff's project and talking to many customers has given us new incentive to get back into the machine work and building, these air cooled engines. We are not the cheapest at doing this work so if price is more important than quality, we are not the place. Its a Timex or Rolex sort of thing. However, our turn around time is probably one of the quickest. I have heard of customers waiting upwards of 12 weeks for engine case work to be done. We just finished some case work for a customer from Canada. Unfortunately, we had an issue with one of our machines which pushed the turn around time back some weeks. Once we received the parts for our machine, the case was line bored the very next day and it will ship out of here tomorrow. For those that want case work etc., done and not prepared to wait upwards of 12 weeks, we are now going to offer a lot more machine work for the air cooled engines. This service will go along with many of the newly designed parts we have made for these older engines. Jeff will be here in June to start building his engine. We are going to use this time to show how we go about assembling these engines. It will include discussing the reason why certain clearances are required, why certain parts need particular checks etc. Hopefully this will be very helpful to many DIY assemblers to show how to and to understand why. Last edited by Neil Harvey; 05-22-2018 at 09:19 PM.. |

||

|

|

|