|

|

|

|

|

|

|

|

|

|

|

Chain fence eating turbo

Join Date: Dec 2008

Location: Austin, TX

Posts: 9,115

|

HAHA, come on. Give yourself more credit! You're sliding in for the home run on your projects!

|

||

|

|

|

|

Registered

Join Date: Jul 2000

Location: So. Calif.

Posts: 19,910

|

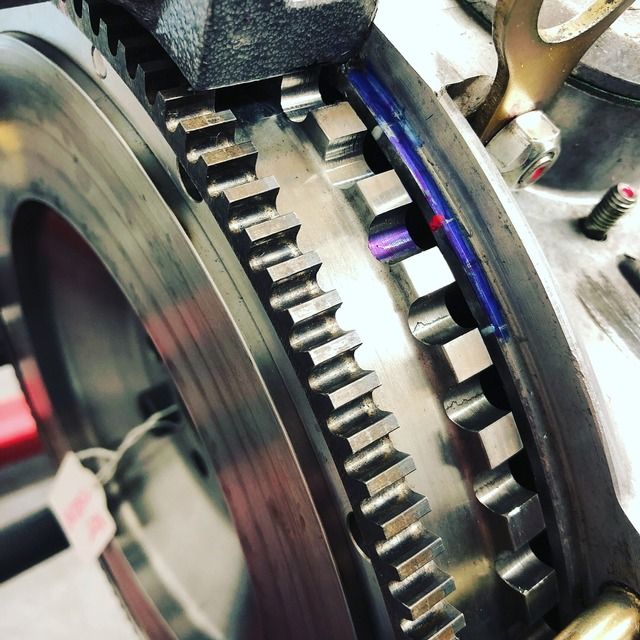

Measuring TDC with a dial indicator gets you pretty close, but the crankshaft can move several degrees while the piston is stationary at/near TDC.

The recommended procedure is to use a positive stop described by ChrisBennet (post #9). However, introducing a hard stop through the spark plug hole can be risky if the valve train is intact (possible valve interference). The slim probe on this "through-spark plug" tool seems to avoid potential contract with opening and closing valves that might not clear with larger stops. Back off the valve adjustment to limit valve lift.  With #1 head removed, a simple TDC tool can be made with a flat plate bolted across the top of the cylinder and a bolt and two nuts through a hole in the middle as a piston stop. This is a commercially available TDC plate.  Sherwood |

||

|

|

|

|

Registered

Join Date: Aug 2004

Location: The Brink

Posts: 2,834

|

All good points raised. I do have a performance cam. I am interested in doing it accurately without buying the Stomski Digidix. That said I am not sure it is truly needed, but the degree wheel is not expensive.

I do see that they are used by others. |

||

|

|

|

|

Kartoffelkopf

|

I like the look of the spark plug stop tool, however, I struggle to get my head around the fact that the dowel-based cam sprockets only allow you to "use this hole, or that one"...it's not that granular, unlike other vernier cam sprockets with infinitely adjustable inner/outer halves, with 3 or 4 bolts that lock one to the other. I'm surprised somebody hasn't developed these for our (aircooled) engines; maybe they're used on the water cooled lumps, no idea.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Irrationally exuberant

|

Quote:

__________________

'80 911 Nogaro blue Phoenix! '07 BMW 328i 245K miles! http://members.rennlist.org/messinwith911s/ |

||

|

|

|

|

Under the radar

Join Date: May 2007

Location: Fortuna, CA. On the Lost Coast near the Emerald Triangle

Posts: 7,129

|

I agree, the one locating pin seems suspect in terms of accuracy. Turns out on my motor the Z1 was spot on.

__________________

Gordon ___________________________________ '71 911 Coupe 3,0L outlawed #56 PCA Redwood Region, GGR, NASA, Speed SF Trackrash's Garage :: My Garage |

||

|

|

|

|

Kartoffelkopf

|

Quote:

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject Last edited by Spenny_b; 12-25-2017 at 02:24 PM.. |

||

|

|

|

|

Ingenieur

|

I found all of these insights very interesting. I am curious, do any of you turn the engine backwards when timing the cams, or always clockwise?

|

||

|

|

|

|

Registered

Join Date: Jul 2000

Location: So. Calif.

Posts: 19,910

|

|||

|

|

|

|

Registered

Join Date: Jan 2015

Posts: 1,499

|

If you miss the TDC mark you can turn backwards (CCW) but go quite a bit, then go CW again to sneek up to the TDC mark. This makes sure all slack is out of the chains as a result of turning CCW.

|

||

|

|

|