|

|

|

|

|

|

|

|

|

|

|

Banned

Join Date: Feb 2003

Posts: 1,207

|

How are the connecting rods on the flat-six arranged?

The crank throws come in pairs and point in opposite directions (see Fig. 5:10) so does that mean for one pair of throws one connecting rod is associated with one side of the motor and the other rod with the opposite side of the motor? I guess it would also be possible for both rods to be associated with just one side of the motor with one piston at TDC when its pair is at BDC.

|

||

|

|

|

|

Platinum Member

Join Date: Jul 2001

Location: Leave the gun. Take the cannoli.

Posts: 21,200

|

Does this help?

__________________

Political polls are often to give you an opinion, not to find out what your opinion is - Scott Adams |

||

|

|

|

|

Banned

Join Date: Feb 2003

Posts: 1,207

|

Thanks, but no ...

|

||

|

|

|

|

Registered

|

Alfred;

It's a great book that you've got there! (Philip Smith's "Design and tuning of competition engines"). In answer to your question, picture the first pair of crank throws being associated with 911 cylinders 1 and 4 (opposing cylinders), the second pair of throws being associated with 2 and 5 and last pair (furthest back) being associated with 3 and 6. Does that help?

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman Last edited by jluetjen; 11-03-2004 at 09:03 AM.. |

||

|

|

|

|

Home of the Whopper

|

I have a .pdf that might help, but can't figure out how to post it.

__________________

“The wave is not the water. The water merely told us about the wave moving by” – Buckminster Fuller |

||

|

|

|

|

Registered

|

Hi BK911;

Haven't seen you posting for a while! You need to export the .pdf to a .jpg. If you can't do it, email it to me and I'll post it.

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|

|

|

Irrationally exuberant

|

Yes, for one pair of throws one connecting rod is associated with one side of the motor and the other rod with the opposite side of the motor.

The pistons are paired 1/4, 2/5, 3/6 such that when one is at the top of it's stroke, the other is also at the top of its stroke. At TDC for #1, #4 is also at TDC. -Chris

__________________

'80 911 Nogaro blue Phoenix! '07 BMW 328i 245K miles! http://members.rennlist.org/messinwith911s/ |

||

|

|

|

|

Registered

|

Quote:

If you need help feel free to Email the PDF to me and I'll post.

__________________

Warren & Ron, may you rest in Peace. |

||

|

|

|

|

Banned

Join Date: Feb 2003

Posts: 1,207

|

Thanks everyone. Jluetjen, the opposing cylinders clue cleared it up for me.

I did some calculations to try to figure out why the flat-six is "inherently balanced" but the flat-four is only in primary balance. What I came up with is that the accelerations of the pistons in the flat-four always sum to 0 and the same is true for the flat-six but when you look at the sum of the accelerations for the pistons on just one side of the motors, then the flat-six is much more balanced compared to the four. The calculations I did were for motors with stroke of 71mm and connecting rod lengths of 131 mm and these are the results I got. Sum of piston accelerations for one side of flat-six.  Sum of piston accelerations for opposite side of flat-six.  Sum of piston accelerations for one side of flat-four.  Sum of piston accelerations for opposite side of flat-four.  For the flat-four, the maximum "unbalance" is 20 and occurs every 90 degrees of crankshaft rotation but for the six the maximum unbalance is only 0.01 and occurs every 30 degrees of crankshaft rotation. |

||

|

|

|

|

Registered

|

Alfred;

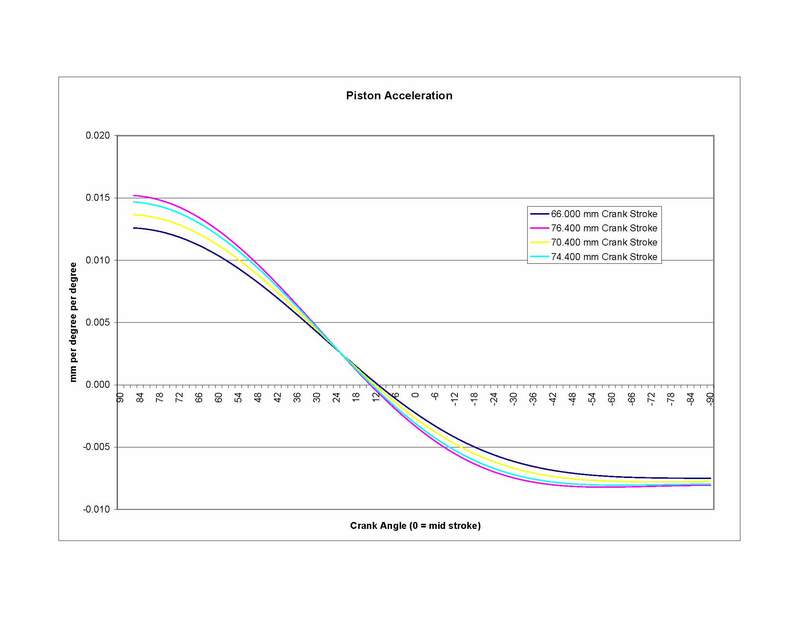

The other part of the "equation" that I don't think that you have captured is second order acceleration. This is because the pistons do not reach their peak speeds at 90 degrees ATDC but rather at 78 to 80 degrees ATD. You can see this in the following charts.  The peak acceleration for the pistons is near TDC and BDC, but the peak lateral acceleration of the rod's big-ends is happening at the 78 to 80 degrees ATD.  Is this reflected in your analysis?

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman Last edited by jluetjen; 11-03-2004 at 11:35 AM.. |

||

|

|

|

|

Registered

|

Here's a stab at the secondary accelerations based on the data that I used to create the rod acceleration graphs.

BTW: I believe that the slight drift in the 120 degree crank data is because I used the old fashioned change in speed over change in distance method for calculating the acceleration rather then using calculus to calculate the instantaneous acceleration. I've forgotten the details of that method in the years since I took calc in High School.

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman Last edited by jluetjen; 11-03-2004 at 12:43 PM.. |

||

|

|

|

|

Registered

|

Here's BK's .pdf

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|

|

|

Banned

Join Date: Feb 2003

Posts: 1,207

|

Thanks for the information. What’s the name of the book that the pdf material is from?

John, below are pics of a diagram I drew and the equations I came up with to describe the position of the connecting rod ends for the flat-six motor. The diagram was drawn to scale for a 35.5 mm throw crank (71 mm stroke) and connecting rods of length 131 mm. The angle, a, is in radians and is measured counter clockwise from the vertical. I'm using Mathematica to do the calculations and plot the graphs. I took the first derivative of the equation for piston 1 in my diagram to find the speed of the piston as a function of the angle of rotation and plotted the graph for 2 full revolutions of the crankshaft to make it easier to see what the piston speed is doing. One place that maximum piston speed occurs is 3.39 rads, which is about 14 degrees after BDC and seems to agree with the yellow curve in your piston speed graph. But, piston speed is also dependent on the length of the connecting rod.

|

||

|

|

|

|

Registered

|

Alfred;

I see that you've obviously remembered the calculus that I've forgotten! BTW, the above .pdfs are not what BK wanted to post. Here's the stuff that I think that you were looking for.   BTW - can you convert your plots into degrees rather then radians?

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|

|

Registered

Join Date: Nov 2002

Location: Planet Eugene

Posts: 4,346

|

Hey - let's use grads!

|

||

|

|

|

|

Moderator

|

__________________

Bill Verburg '76 Carrera 3.6RS(nee C3/hotrod), '95 993RS/CS(clone) | Pelican Home |Rennlist Wheels |Rennlist Brakes | |

||

|

|

|

|

Banned

Join Date: Feb 2003

Posts: 1,207

|

Here's the graph of piston speed as a function of the angle a measured in degrees.

Last edited by Alfred1; 11-03-2004 at 05:05 PM.. |

||

|

|

|

|

Home of the Whopper

|

Some of you have expressed interest in the book I was using. It is:

Advanced Engine Technology Heinz Heisler SAE ISBN 1 56091 734 2 Enjoy! BK

__________________

“The wave is not the water. The water merely told us about the wave moving by” – Buckminster Fuller |

||

|

|

|

|

Registered

|

BK;

He's got a couple of books out: "Advanced Engine Technology" and "Vehicle and Engine Technology". Do you know if there is an overlap between the two?

__________________

John '69 911E "It's a poor craftsman who blames their tools" -- Unknown "Any suspension -- no matter how poorly designed -- can be made to work reasonably well if you just stop it from moving." -- Colin Chapman |

||

|

|

|

|

Banned

Join Date: Feb 2003

Posts: 1,207

|

Quote:

|

||

|

|

|