|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Dec 2001

Location: Off grid in Eastern ONtario

Posts: 234

|

Valve spring pressure

Finally getting to reassembling my heads (new guides, reground seats and valves) and I have a decision about the valve spring setting.

My springs are not stock - they are longer than stock, with a lower spring rate. They were sourced from CMW several years ago. From info I have found, the stock springs have a rate of about 290 lb/in, and installed at the 34.5mm height the initial force is 130 #. At 11.5mm lift, the force rises to 262#. Turns out this is bad information - or at least I interpreted it incorrectly My springs have a rate of 260 lb/in. I can set the initial force the same as stock, then the force at 11.5mm will be 254#, a bit lower than stock. Or I can set the springs so that they are the same as stock when open; in that case the initial force will be a bit higher than stock, at 136#. Or I can choose something else, including setting the intakes and exhausts at different points. The force rise at 11.5mm lift is 127#; at 10mm it is 109#. I can't change those values. I suspect that for a mildly tweaked engine with stock cams, none of this really matters, but I have to re-shim in any case so thought I'd seek some input.

__________________

Bob D. '84 Carrera - MAF, Wong chip, RSR flywheel, ER bushings and other bits, CTR fiberglass F/R bumpers, 7/9 Fuchs, 22/27 TB, 22/21 SB, bunch of other little stuff '69 Lotus 7 Series 3; '74 Fiat X1/9 '14 X5 diesel Last edited by bdonally; 12-18-2018 at 05:40 PM.. Reason: clarification |

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 874

|

If I am reading this correctly, are you saying that at the factory installed height you have 130lbs as seat pressure?

If this is so, that is way too much. In just about everything I read and see, these heads are always over sprung. Another dimension that is critical that you do not mention and hopefully have checked is the coil bind distance. You need to measure each valve's retainer height, then calculate the require seat pressure and shim to make them all the same. Seat pressure is based upon the valve diameter, the actual weights of the valves, retainers and locks, seat widths and use. In most cases with the air cooled heads, a seat pressure of 70 - 75 lbs will be ok. If you are running conservative RPM, this will work. If you intend to run higher RPM, then the open pressure needs to be increased. Its impossible to say exactly what you need as many factors come into play. Cam choice, max RPM, Turbo or NA application and the spring itself all play a huge role here. Often, the cam design requires over springing to dampen the harmonics created by poor design. The spring itself requires careful attention. In a lot of cases with aftermarket springs, there are too many active coils and when the valve is open, the distance between the coils is too large. The spring then start to wobble and move around. As long as you are running a simple stock application, this will not be a deal breaker, but it something that should be known. But the seat pressure is. If you are planning on running 130 lbs seat pressure, and all you need is 70, that's 60lbs additional force your engine has to turn against. Every revolution the engine turns, it turns against 60lbs x 6 and 60lbs x 12 for each engine cycle. If your engine makes 180 - 250 HP, you are giving away quite a lot of HP just to turn the engine over. Add this to what you are losing with friction, cam timing changes with valve train harmonics etc, your engine could have more performance. In the performance world, we look at the measured performance of an engine and its calculated performance. The difference between the two are the parasitic losses caused by all of the inefficiencies. We work in this area to gain performance. Valve spring pressures are a huge contributor to power loss. Cam design and lowering the spring pressures are an on going pursuit. Last edited by Neil Harvey; 11-29-2018 at 08:06 AM.. |

||

|

|

|

|

Registered

Join Date: Dec 2001

Location: Off grid in Eastern ONtario

Posts: 234

|

I understand all the points you raise.

Various sources provide some data for checking the stock springs: height force 42mm 20kg 31.5mm 75kg 30.5mm 80 kg Using this info, the spring rate is 290 #/in and at the installed height of 34.5mm the seat force is 130#, rising to 262# at 11.5mm lift. Lowering that pressure involves a much lighter spring, possibly achievable by leaving out the inner spring. Or setting a greater installed height. Neither of those options would seem doable without a fairly significant development program. I wonder if there is any experience out there? In any case, I am using stock ( presumably fairly mild) cams, stock valves, Ti retainers, and a 6800 redline, with 6500 as a normal shift point. The CMW springs were installed by a previous owner in preparation for racing that never happened. They are about 5mm longer than stock, and the design results in a lower spring stress and they are a bit further away from binding. Sounds to me that I'd be pretty safe if I set them at a bit lower than stock.

__________________

Bob D. '84 Carrera - MAF, Wong chip, RSR flywheel, ER bushings and other bits, CTR fiberglass F/R bumpers, 7/9 Fuchs, 22/27 TB, 22/21 SB, bunch of other little stuff '69 Lotus 7 Series 3; '74 Fiat X1/9 '14 X5 diesel |

||

|

|

|

|

Under the radar

Join Date: May 2007

Location: Fortuna, CA. On the Lost Coast near the Emerald Triangle

Posts: 7,129

|

Measure your actual spring pressure at the installed height and full lift. But for stock cams, I would use stock springs set to factory specs.

__________________

Gordon ___________________________________ '71 911 Coupe 3,0L outlawed #56 PCA Redwood Region, GGR, NASA, Speed SF Trackrash's Garage :: My Garage |

||

|

|

|

|

Registered

Join Date: May 2004

Location: Boulder, Colorado

Posts: 7,275

|

Bob - shift points should be determined by using a dyno derived torque curve, and applying it to your gear ratios. It isn't related to a mechanical red line (set by where thing break, or where wear increases more than you can stand, or perhaps where valves float even if they don't hit pistons). Of course, if the optimum upshift RPM is beyond a mechanical limit - as is often the case with 1st to 2d - you shift at the limit.

You can also establish it with data from the track (or highway??). You want the acceleration in the old gear to be the same in the new gear. If there is a mismatch, you either shifted too early or too late, and in any case gave up something in terms of maximum acceleration. Is one of these how you came up with 6,500? |

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 874

|

Your engine will run with what you have, but lots of things wrong with what you are doing.

Your installed seat pressures are way too high and you will wear out parts. The motion of the Porsche rocker face to the cam lobe creates contact stresses that are one of the highest in valve train geometry. Why are you using Titanium retainers if your RPM limit is 6800? Titanium should not be used in a street engine unless you are rev'ing very high, have a fast opening cam design and the valve train weights are an issue. They are typically "over sold" and give zero return. On top of this, you are running huge seat pressures. With the seat pressures you are suggesting to run, you will probably have issues with the Titanium retainers. Could have issues with the stock ones too. Best to have them magnufluxed to check they are not already cracked if you decide to swap. Change the springs to stock springs and run 70 -75 lbs on the seat. I think with stock installed heights, the seat pressures may be around 80 lbs with some shims under the seat base. You need to measure the retainer heights and select the shortest one on both the intake and exhaust sides, then test whatever spring you are going to use. Measure the spring pressures at these heights, at full valve lift and the coil bind distance. Then shim each valve to obtain the same or as close as possible equal seat pressures. Remember to "bull dog" each spring to coil bind before measuring to remove any manufacturing stresses. If you do not do this and go with the spec heights with non factory springs, you may in trouble with broken parts in your future. |

||

|

|

|

|

|

Registered

Join Date: Mar 2004

Location: So. Ca.

Posts: 521

|

Quote:

Just check I am sure you will come to a different conculsion. regards |

||

|

|

|

|

Registered

Join Date: Dec 2001

Location: Off grid in Eastern ONtario

Posts: 234

|

Unfortunately I don't have any stock springs to measure, I have been relying on info from various sources.

I do know that the springs have been in the engine for about 20 years and many track miles, and that the rest pressure is about 130. I now suspect that the increased forces and hence the torque required to drive the cam might explain why the IM aluminum gear have up. The failure of that gear is the reason I tore down the engine . It would be nice to know the stock seat force, likely there is some discrepancy between the checking method and the installed height. Need to think about this a bit but it sounds like the springs (and upper and lower retainers) are needed. Dang |

||

|

|

|

|

Registered

Join Date: Dec 2001

Location: Off grid in Eastern ONtario

Posts: 234

|

Quote:

With the CR gears that have been in the box for a long time, shift at 6300-6500 are ideal; 6800 is set in the ECU to allow a little leeway. With the stock gears, the shifts are a bit higher. I hadn't analyzed this earlier - the gears were in the car when I bought it - but it looks like a lot of money for little gain given the more or less stock engine. In fact, running a simple model to calculate accel time from 95 km/hr (60mph) to 220 km/hr (135 mph) shows that the stock gearing time is about the same as the CR gears, maybe a little faster. Think I am going to stick the stock gears back in, because a spin off is that at 65 mph the engine is revving at about 3500 vs 3000 stock. Anyway, this is a bit off topic regarding the original valve spring question, other than pointing out the folly of making a bunch of changes without really thinking through the benefits.

__________________

Bob D. '84 Carrera - MAF, Wong chip, RSR flywheel, ER bushings and other bits, CTR fiberglass F/R bumpers, 7/9 Fuchs, 22/27 TB, 22/21 SB, bunch of other little stuff '69 Lotus 7 Series 3; '74 Fiat X1/9 '14 X5 diesel |

||

|

|

|

|

Under the radar

Join Date: May 2007

Location: Fortuna, CA. On the Lost Coast near the Emerald Triangle

Posts: 7,129

|

It is easy to set up a spring pressure measurement device. A long bar with a pivot on one end and a weight hung along the other on a scale. A caliper was used to measure the spring height.

__________________

Gordon ___________________________________ '71 911 Coupe 3,0L outlawed #56 PCA Redwood Region, GGR, NASA, Speed SF Trackrash's Garage :: My Garage |

||

|

|

|

|

Registered

Join Date: Jul 2005

Location: Atlanta

Posts: 1,241

|

Stock springs were used with racing cams by Porsche, but with lighter rockers. It is rare that more than 70-75lbs seat pressure and 240-250lbs over the nose with 12.5mm lift is required with stock components.

__________________

No physical quantity completely explains its own existence |

||

|

|

|

|

Registered

Join Date: Dec 2001

Location: Off grid in Eastern ONtario

Posts: 234

|

I have a decent setup for measuring springs, and have ordered a set of stock springs.

Once they arrive I'll figure out where things went off track.

__________________

Bob D. '84 Carrera - MAF, Wong chip, RSR flywheel, ER bushings and other bits, CTR fiberglass F/R bumpers, 7/9 Fuchs, 22/27 TB, 22/21 SB, bunch of other little stuff '69 Lotus 7 Series 3; '74 Fiat X1/9 '14 X5 diesel |

||

|

|

|

|

|

Registered

|

Gord, your home brew set up for measuring spring pressure checking is fantastic. I envision cutting a piece of welding rod or similar the same as the assembled height length to make it just that much easier.

__________________

1986 Targa Guards Red 2021 MT09 SP |

||

|

|

|

|

Under the radar

Join Date: May 2007

Location: Fortuna, CA. On the Lost Coast near the Emerald Triangle

Posts: 7,129

|

Glad you like my DIY solution. Actually I found that my caliper's depth gauge worked really well to measure the height.

__________________

Gordon ___________________________________ '71 911 Coupe 3,0L outlawed #56 PCA Redwood Region, GGR, NASA, Speed SF Trackrash's Garage :: My Garage |

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 874

|

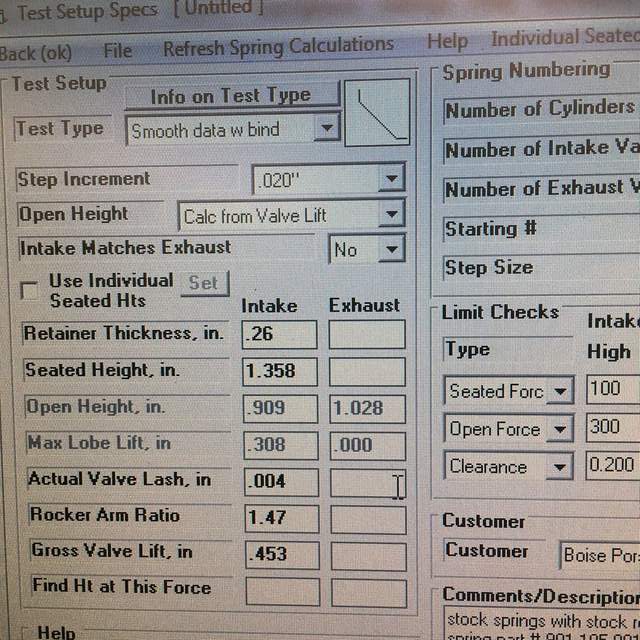

Here you go.

Stock retainer and base with stock spring 901 105 901 51 |

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 874

|

opps upside down,

|

||

|

|

|

|

Registered

Join Date: May 2004

Posts: 874

|

If someone can let me know how to flip the images, please do.

|

||

|

|

|

|

Under the radar

Join Date: May 2007

Location: Fortuna, CA. On the Lost Coast near the Emerald Triangle

Posts: 7,129

|

So, from your chart the installed seat pressure is 60 -65 lbs?

__________________

Gordon ___________________________________ '71 911 Coupe 3,0L outlawed #56 PCA Redwood Region, GGR, NASA, Speed SF Trackrash's Garage :: My Garage |

||

|

|

|

|

Registered

Join Date: Jul 2006

Location: S. Florida

Posts: 7,249

|

Hi Neil, I saved your pics, rotated them, and then reposted them. Glad to help if I can

|

||

|

|

|

|

Registered

Join Date: Dec 2001

Location: Off grid in Eastern ONtario

Posts: 234

|

This is really helpful. Thanks for taking the time to gather the info.

New springs retainers and seats arrive Friday and I'll compare to this info.

__________________

Bob D. '84 Carrera - MAF, Wong chip, RSR flywheel, ER bushings and other bits, CTR fiberglass F/R bumpers, 7/9 Fuchs, 22/27 TB, 22/21 SB, bunch of other little stuff '69 Lotus 7 Series 3; '74 Fiat X1/9 '14 X5 diesel |

||

|

|

|