|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

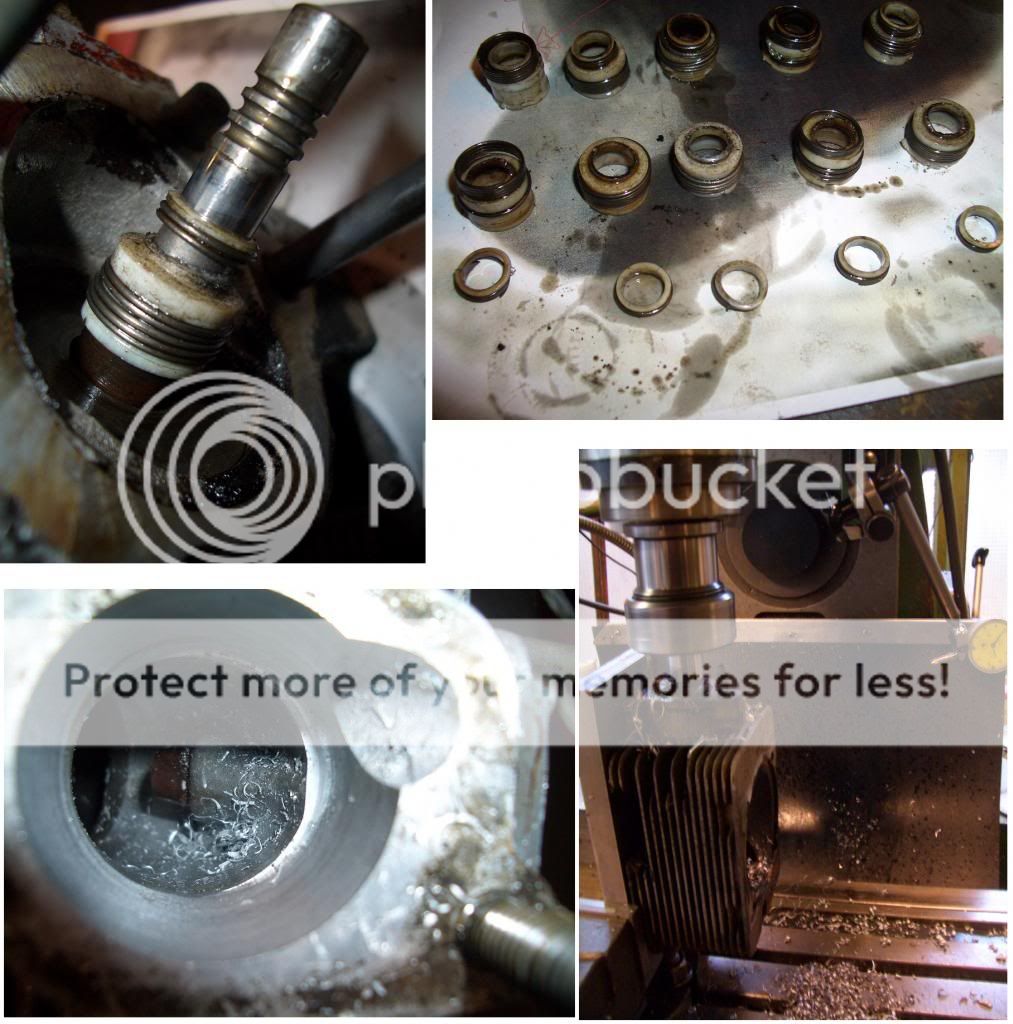

I did some work yesterday, intakes are done, exhaust I will do later today.

I found half of the valve stem seals torn in half.

|

||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

|||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

|||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

|||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

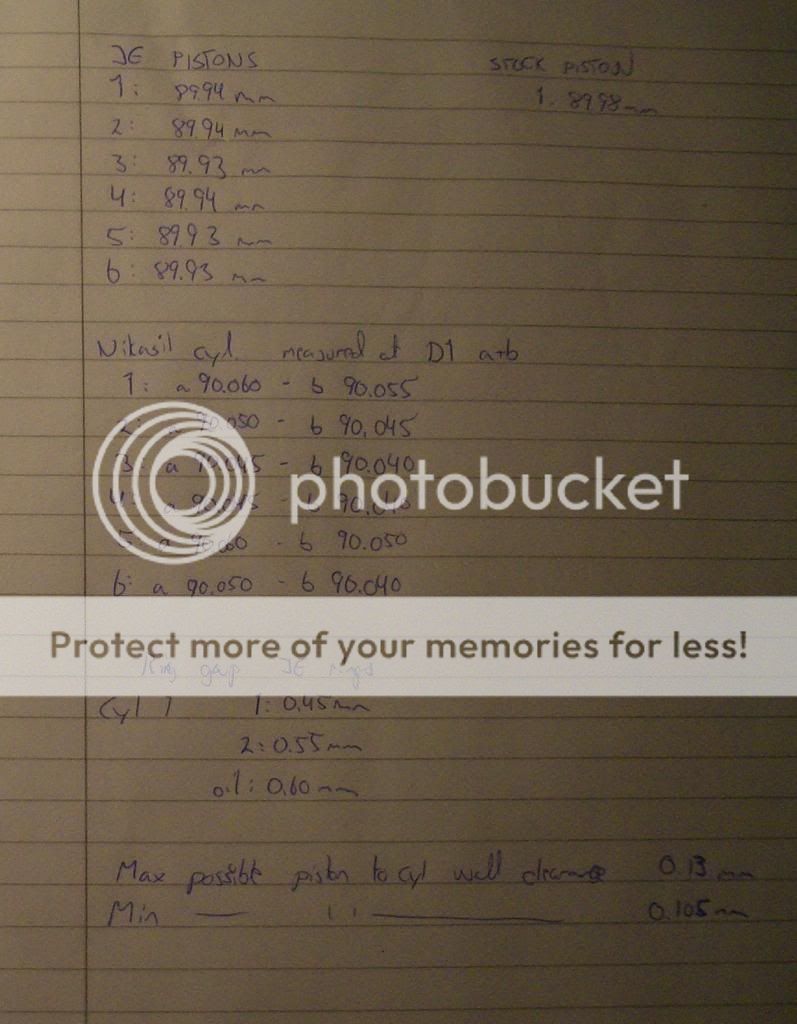

And hmmmm, I have the largest cyl/pist combo (group2), and small JE's...

I've read other posts here that ideal p/c clearance to be 0.0381mm/ 0.0015" And I'm at 0.11mm / 0.004" if I mix large piston with large cyl etc. Ovalness is within 1 hundreth of a millimeter so that part is good. So what to do with the P/C clearance? get custom JE's?

Last edited by Neffets; 02-04-2014 at 11:40 AM.. |

||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

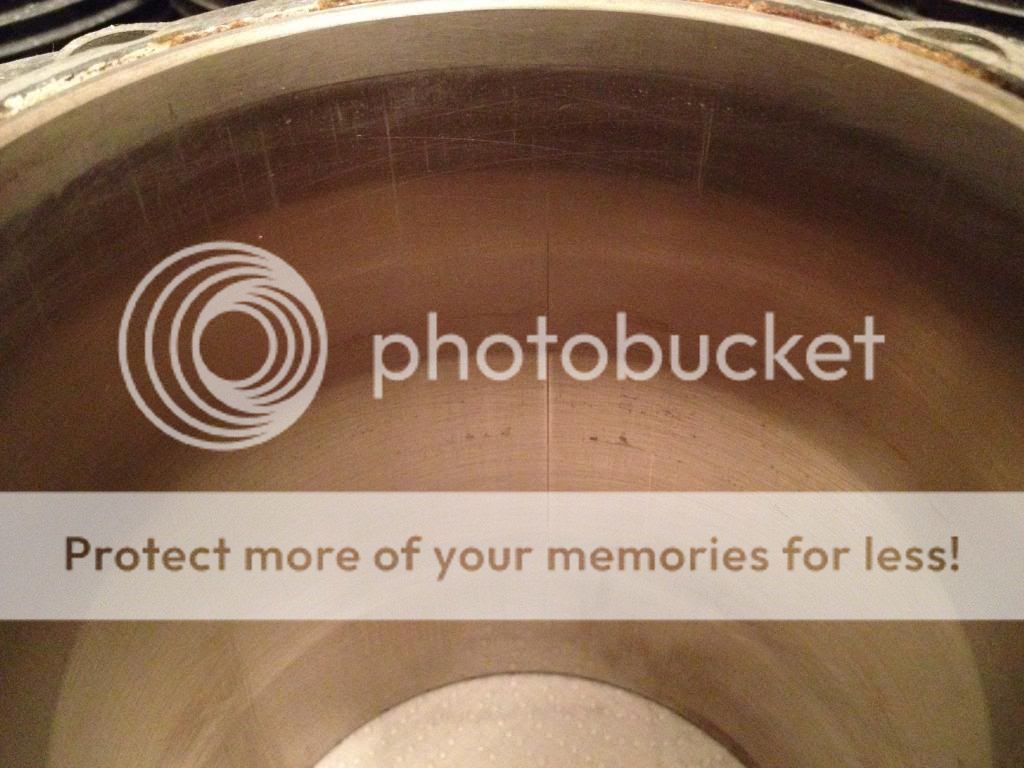

I went to measure again but this time with a scale that reads 1 thousanth of a millimeter,

and then I found this ... So now they will go to us chrome to be coated&honed with nikasil 0.04mm larger then my JE's. I measured my cylinders to 4 RA where the piston rings move and the bottom of the cylinder is 7.2 RA US Chrome says they will hone to between 4-8 RA, and two weeks turn around time.

|

||

|

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

|||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

Last edited by Neffets; 02-26-2014 at 02:30 PM.. |

||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

All cyl heads are now within 0.02mm in height differnece, same goes for cylinders

|

||

|

|

|

|

abit off center

|

How much did you have to take of the heads to clean them up?

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

0,35mm, I read somewhere that there is a max to how much one can take of, but I can't find it.I guess I will add a 0.25 extra copper shim in addition to the 0.5mm i have underneath the cylinders.

|

||

|

|

|

|

abit off center

|

Yea .25mm is the max that's to keep within the limits of the chain tensioners and chain box centering without modifications to them. Stock measurement from the cam carrier top of the head to the sealing surface is 84.5mm

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

|

Registered User

Join Date: Feb 2014

Location: New Zealand

Posts: 71

|

Awesome thread. Your not interested in selling the carb setup are you?

|

||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

So today I checked the torque on my case throug bolts and the M8's, they were all to loose, the through bolts are supposed to be 35Nm, they were around 20nm. Torqued all to spec, and checked crankshaft end play to be 0.22mm

Max is 0.3mm, new I think i read something between 0.12-0.19mm Then looking at the valves for my cylinder heads, alle the exhaust guides are shoot, measured 0,6mm radial play.... Intakes are good. took out the guides using the method in this thread, worked as a charm. Valve Guide Removal

|

||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

So now I need to order new valve guides, and then cut the seats.

I borrowed a set from a friend, I see in Bruce's book that the seat angles are 30-45-75 degrees. The valve seats at 45 degrees. Are both the valve and the seat 45 degrees? The tool I borrowed is 46 degrees?

Last edited by Neffets; 02-28-2014 at 02:37 PM.. |

||

|

|

|

|

abit off center

|

Your talking Interference Angle or "pinch" cut the seat and lightly lap the valve and you will see the benefits mostly with air cooled engines. Nice cutters, I have 12 different ones. You have a Valve Concentricity Gauge?

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. Last edited by cgarr; 02-28-2014 at 01:40 PM.. |

||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

hm not sure I got that, do I use the 46degree tool or do I need a 45?

What is a Valve Concentricity Gauge? I have tools to measure the roundness of the valve seat. And I have the cutting tool to straighten the valve sealing surface. this engine needs more and more parts every day, and I hate waiting for parts

|

||

|

|

|

|

abit off center

|

The neway kit for Porsche uses cutter 642 and 272 are those the ones you have?

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|

|

Registered

Join Date: Jan 2013

Posts: 148

|

I have 203/212/217/622

The 622&217 will do the job on the exhaust valves. They are too small for the intake. Found this as well 203 Cutter- 1-1/4" dia. 31° x 46° 212 Cutter- 1-1/4"dia. 15° x 75° 217 Cutter-1-1/2"dia. 15° x75° 622 Cutter- 1-1/2"dia. 31° x 46° 619 Cutter- 1-1/2"dia. 15° x 60° 216 Cutter- 1-1/2"dia. 75° 642 Cutter- 1-3/4" dia. 31° x 46° 272 Cutter- 1-3/4"dia. 75° |

||

|

|

|

|

abit off center

|

Another 2.7 rebuild +ITB&EFI

Oh that's right your doing 2.7 heads, that 622 is too small for those intakes? Might have to get the 642 for that? You can extend those cutters to their limits?

__________________

______________________ Craig G2Performance Twinplug, head work, case savers, rockers arms, etc. |

||

|

|

|