|

|

|

|

|

|

|

|

|

|

|

Registered

|

Innovate LC-2 wideband - pros, cons, last straw

Innovate’s LC-2 system was bought to help solve the puzzle of my just-rebuilt 3.2 getting 10 mpg city. Wasn’t acquired for their hardware given nonstellar reviews. It was for their software, LogWorks. The draw in my case: streaming data. This post shares what I experienced with these Innovate products. The highs, lows, my “portable” build, and the logs that provided the first glimpse into the source of my engine’s unruly fuel appetite. The “last straw” is the point where my patience to keep this gear running, runs out.

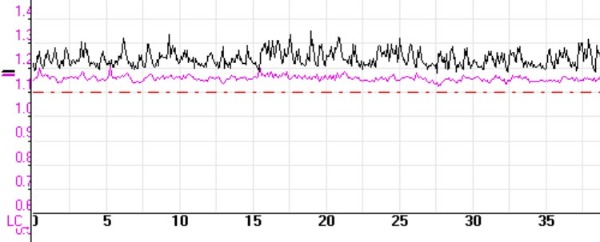

LC-2 kit. $180. from Innovate’s website. When LC-n’t2 hardware works properly, it’s an impressively insightful tool. Doing this reliably didn’t happen. To illustrate what went on, I’ll share logs. Both good & bad. In all of them, O2 levels are in lambda as opposed to AFR. 14.7 AFR = 1.0 Lambda. This level—stoich—is indicated by the dash-dot red line in each log. Engine’s doing its 10 mpg thing here so consider traceline levels accordingly. There are two tracelines. Engine’s 1-2-3 side is green. 4-5-6, blue. Good data When tracelines have what is learned to be a normal appearance to them, that’s good data…  Engine at warm idle. Spikes are quick throttle pushes.  WOT run. 4th gear doesn’t get far as pavement runs out. Favorable lambda at WOT according to Google AI: At wide open throttle (WOT) on a gasoline engine, the ideal lambda value, which represents the air-fuel ratio, typically falls within the range of 0.79 to 0.92, according to Summit Racing. This corresponds to an air-fuel ratio (AFR) of approximately 11.5:1 to 13.3:1. Naturally aspirated engines often operate closer to the richer end of this range (around 0.85 lambda or 12.5-13.0 AFR), while forced induction (turbocharged or supercharged) engines may benefit from slightly richer mixtures (around 0.75-0.80 lambda or 11.0-12.0 AFR) for cooling and preventing detonation.Another: Naturally Aspirated Engines: A lambda value of approximately 0.85 to 0.91 is common for gasoline engines at WOT. This range provides a good balance of power and engine protection. My engine at WOT looks to average around 8.5. Maybe slightly lower. Bad data When tracelines have an odd appearance—based again on comparative experience—there’s a hardware glitch. Sometimes it’s obvious from the log there’s something wrong. Other times, it can be subtle. I didn’t keep detailed notes when faced with bad data. Instead, I got on with diagnosing to find the fault. Then fixing it.  City drive.  Highway. 80 - 85 mph.  Cold idle. Single bank. Telling good from bad data If engine’s state is known—as in no recent fiddling with it—and traceline appearance remains reasonably consistent log to log, OK. If all of a sudden tracelines appear unusual compared to a previous log and does so while the engine’s state is known, bad data has arrived / hardware is glitching. Why didn’t I return the hardware to Innovate after the first fault appeared? I’m not good at that. Innovate tech support I spoke with Innovate’s tech support a few times about whatever glitch was currently in hand. They were politely useless on each occasion. Option: ship Innovate’s product back to them for their inspection of it. They want 2 weeks for this. Add shipping time… Roughly 3 weeks is invested in whatever Innovate will or won’t accomplish. Given the expertise level demonstrated by their tech support, I never considered this path being worthwhile. Was quicker, though certainly more time consuming for me, to deal with each glitch DIY. Testing engine components with wideband Fuel injectors were prime suspects in the hunt for why my engine was guzzling fuel. I have a set of Lucas D1540BA (from FiveO) and stock Bosch 158. Both sets were cleaned and tested by Bill in Idaho and passed. I also had a wideband look at them…  Power to each injector is disconnected one at a time (connector at injector’s top) for just a few seconds. If no difference in the traceline, or little difference compared to other cylinders… bad news for that injector and/or its circuit. According to the log above, there’s no sign of injector or injector circuit fault in 4-5-6. 1-2-3 tested the same. Did you see the drop in 1-2-3 side (green) traceline when a 4-5-6 side injector is disabled? Is this a genuine richening of the 1-2-3 side? Or, a visual fiction created by the Innovate system? No answer to this. I saw other traceline anomalies like this. It’s possible to get sucked into these quirks attempting to make sense of them. Eventually, I concluded the data relating specifically to the test being performed was necessary to deem good or bad. Testing the injectors here, this is good data. The 1-2-3 side dip = irrelevant. Air The engine leaking or naturally flowing more air was considered a 10 mpg causality. I didn’t think there was a leak but the engine—during rebuild—got 964 cams, SSI exhaust, and Dansk sport muffler. Did this combo drastically increase air flow so nearly twice the fuel was called for? With others having done these mods and there being no mpg complaints, why is my engine fuel wonky? In any case, air leaks were searched for. While digging for leaks, my brake booster was not entirely well. One day during the air leak hunt, booster completely failed. It’s surprising how much assist these boosters generate. It’s still possible to fully brake without the boost but the pressure to do so is significant. Booster was rebuilt and the vacuum hoses replaced with new. Great for braking! 10 mpg persisted. No other air leaks were found.  To see how the O2 sensors would respond to an air leak, one was created. One of the two clamps that secures the rubber collar between the intake manifolds (3.2 intake) was loosened. Sensors recognized this air immediately. Gaps between tracelines seen here and in other logs, I never figured out what caused this. Sometimes tracelines gapped. Sometimes not. To be continued... .

__________________

Karl ~~~ Current: '80 Silver Targa w /'85 3.2. 964 cams, SSI, Dansk 2 in 1 out muf, custom fuel feed with spin on filter Prior: '77 Copper 924. '73 Black 914. '74 White Carrera. '79 Silver, Black, Anthracite 930s. |

||

|

|

|

|

Registered

|

AFM adjustment

Among adjustments possible in an AFM—that affect air-fuel—is the notched dial inside this unit. Clockwise adjustment of this notched dial leans. Counter clockwise richens. I went clockwise…  Stock position of notched dial - city drive.  Dial adjusted 3 notches clockwise - city drive. Engine’s performance after this adjustment = terrible. A rodeo-ride. No power. Dial is returned to its original position. Good engine performance returns. I wasn’t sure but didn’t think the AFM was the 10 mpg culprit. If I was going to have it worked on… AFM testing and/or restoration Should you have any issue with your AFM and want expert assistance, Sal Carceller, “Scarceller” here on PPF is the person to speak with. Highly recommended. Portable build After wideband served its purpose, I planned to remove—and put in storage—whatever hardware could be made portable. This in mind, I built the guts of the system into a briefcase. Great idea? Yes, because, had Innovate’s hardware been built into some discreet, difficult-to-access nook in the car, doing so would have complicated the effort needed to shuffle parts & wires around to diagnose Innovate’s continuing issues. With the briefcase sitting on the rear squab deck, there was easy access to at least some of the system.   Case in working mode on the rear squab. Power cable and ground are visible to the right. Data cable leading to my laptop is a thin cable with a small, white tag on it. Relays are the 2 red-colored items. White boxes are power filters. Two controllers are the black items just beyond the power filters. Controller cables that connect to the extension cables that run to the O2 sensors, these are to the left of the controllers. Space in the case that was left over is used for storage. Plastic bag contains odds & ends related to the system—extra 4.9 O2 sensors, op manual, bung plugs and crush washers, Allen to manage the plugs in & out of the bungs.  EVERY electrical part and wire here was doggidly tested to ensure, from the get go, everything functioning as it should. When issues began presenting, the entire system was tested (repeatedly according to demand) in order to isolate where a glitch was located. On each & every occasion, the problem du jour was found within the area titled: “INNOVATE HARDWARE.” The problem with Innovate hardware problems: once tested, components weren’t to be trusted. So when the next glitch surfaced, retesting what had already been tested was obligatory. I also tested the hardware I installed again & again so the process of elimination was all-inclusive. Time consuming? Indeed. Ground On each occasion I spoke with Innovate’s very polite tech support, the same question was asked of me…“How’s your system grounded?” My reply: “All Innovate-related ground wires are run to a single post. Main ground is a cable fixed to the car’s chassis that secures to the post with a wingnut. Ground connections are clean and fastening is uber tight at both ends. I know a system’s power & ground must both be spot on for everything in between to do as it should.” I also mentioned there being voltage regulators and power filters included in the system’s 2 dedicated circuits. After my providing this input, the tech support person I spoke with—on each occasion—could add nothing to help diagnose the problem with the product they represented. Power circuits Main power was taken directly from the car’s battery in two dedicated circuits, run through fuses, then through voltage regulators. These mains consolidated with two dedicated relay circuits with this relay power (ignition ON/OFF power) taken from the stock fuse panel. The lot of these wires then run through a 4-wire cable that feeds from the frunk into the cabin terminating behind the driver’s seat. At the end is a quick-connect that plugs into a receptacle that’s mounted in the briefcase. Dual power circuits were run—for the dual O2 sensors & controllers—because I didn’t see any other good way to serve power. Maybe there is. Given Innovate’s glitching, multiple power circuits feeding into the briefcase proved beneficial for trouble shooting. Voltage regulators and power filters VRs were included based on seeing a YTube fellow who solved his Innovate issues by adding VRs. Whether his vid is fact or fiction, no telling. I went with his premise to avoid doing so after the system had been built out. Power filters were included by default. O2 Sensors LC-2 kit comes with a 4.9 O2 sensor. I’ve just looked back into my bag of sensors and some have a Bosch branding and some don’t. I have 6 of them. Unfortunately tracking where each sensor came from was not done. Mistake as I’d now like to know what source supplied the non-Bosch sensors. It’s my intel that 4.9 O2 sensors are damaged by being in the exhaust stream in an unpowered state. If my wideband was offline for any reason and driving was necessary, out came both sensors and plugs went into their bungs. System back in order… sensors went back in—back in where they came from so calibration was NOT necessary. Otherwise it would be. New sensors going in with Innovate hardware need to be “free-air” calibrated outside of the exhaust prior to installing them. While calibration will determine if a sensor is heating up or not—-signally this with the LED status light in the controller—it’s possible to eyeball the working end to confirm this status should a wideband system with no LED status be in use. When powered, working end of O2 sensor gets very hot very fast. Heat resistant antiseize on these threads is factory applied. One of my O2 sensors failed after less than a few months in service. I can’t say where this failed sensor was from. Mistake. I can say it was not a Bosch. Can also be said there’s something wrong with an O2 sensor—or the associated hardware that sends a death-signal to a sensor—for a sensor to quit in just a few months of service. Innovate cables O2 sensor cables included in the LC-2 kit are long enough to run from the exhaust up through the engine tin and into the engine bay with several inches of length to play with in the bay. As I know it and for the moment, Innovate offers these cables in one length only.  To easily pass O2 sensors from the engine bay down through the engine tin to the exhaust… I enlarged the stock O2 hole in the 1-2-3 side tin to fit a large, “x-cut” grommet. Same hole & grommet was put in the 4-5-6 side tin. Whether this hole making is possible with the side tins installed… might be with a small drill. I removed both tins for this. Hole edges were touched with paint as this metal will rust if left naked. Alternate route: pass sensors between the engine bay’s double-lipped rubber seal and the tin. I tried this. Once.  Given sensors coming and going multiple times to diagnose & correct Innovate hardware issues, the x-cut grommets in the tin were far more useful than expected. Grommet source: search MIZORLIE grommets on Amazon. Extension cables To reach from sensor cable ends to Innovate’s controllers, Innovate sells extension cables in various lengths. What length is needed of course depends on the system’s configuration. I ran these extension cables (2 of them) from the engine bay, through the car’s bulkhead to the driver’s side squab area (where briefcase sits.) A single hole was drilled in the bulkhead suitable for a grommet that’s suitable to fit both Innovate cable-ends through. The extension cable ends that insert this grommet are specifically the ends that connect to the controller cables—these are the smaller connectors at the cable’s 2 ends. A single hole was drilled from the cabin side into the engine bay after calculating where the hole would end up being in the engine bay. Cables were passed through the grommet—tight fit—then the grommet was positioned in the hole with silicone sealer in the grommet’s recess. Getting paint onto the rim of the hole was less convenient. Once the 2 extension cables enter the cabin on the passenger’s side, rear corner, just below the squab deck, both cables were run behind the carpeting and exit between and below the squab deck. These two extension cables connect to their respective controller in the briefcase. Can controllers be mounted in the engine bay? I don’t know. To be continued... .

__________________

Karl ~~~ Current: '80 Silver Targa w /'85 3.2. 964 cams, SSI, Dansk 2 in 1 out muf, custom fuel feed with spin on filter Prior: '77 Copper 924. '73 Black 914. '74 White Carrera. '79 Silver, Black, Anthracite 930s. |

||

|

|

|

|

Registered

|

Extension cable’s path in engine bay - mistake made

1-2-3 side extension cable was originally run across the front of the engine (clutch side) to the hole that makes passage into the cabin. Thought I positioned this cable on the crossbeam, not the engine. In any case, that path was a mistake. Sufficient heat got to the cable and the cable melted through in one small area. Wideband data dropping entirely off screen when this happened. Controller’s LED blinks red when the sensor is not properly connected, or otherwise not working. A new Innovate extension cable for the 1-2-3 side was run along the back of the engine back (fan side) and up along the right side to the passage hole. Tucked away in this path, much of this cable’s run can be made invisible while it remains easy to access. Importantly, it’s not near any hot spot. Innovate’s free-air calibration While some wideband systems don’t call for calibrating, Innovate’s LC-2 system does. Sensors need to be removed from the exhaust for this. With sensors in “free-air,” ambient air, Innovate’s multi-step calibration process is performed. User’s manual details this process. What calibration does is pair a given O2 sensor to the Innovate controller that sensor is connected to. Pairing allows the controller to supposedly compensate for sensor wear and for what altitude the sensor is operating at. Swap either a controller or an O2 sensor after they have been paired by calibration and… free-air calibration needs to be performed again to pair the newly associated components. While Innovate’s LC-2 product manual advises (as I write this) that calibration be performed when a “new” sensor is installed, this is not the entire guidance needed. What Innovate fails to mention is calibration being necessary when existing sensors OR controllers are swapped within a system, or a replacement controller is installed. Surely some users don’t figure this important detail out and so potentially face issues that would otherwise not exist. More, never was this re-pairing of hardware advised to me by tech support as a potential solution to ANY issue I discussed with them. I eventually questioned this re-pairing during one tech discussion to see if the truth would be told. It was. Intentional concealment on the part of Innovate in this regard? I think so. Swapping and/or replacing controllers, swapping and/or replacing O2 sensors any number of times to diagnose—and fix—system faults became routine. Each time this is done, O2 sensors must be removed from the exhaust and free-air calibration performed. Given ongoing hardware issues as I encountered, much time was dedicated to the re-calibrating process. Getting data from the wideband hardware to a laptop Data gets from a dual set of Innovate’s controllers by first connecting the two controllers together with the Innovate-supplied “patch cable.” Innovate refers to this as “daisy chaining.” To make this chain, each controller has an “IN” and “OUT” 4-wire cable. These are clearly labeled. “OUT” of one controller connects with the patch cable to the next controller’s “IN” cable. Then that controller’s “OUT” cable connects to the serial data cable (provided by Innovate) that in turn connects to a serial-to-USB cable (purchased separately) that in turn connects to a laptop running LogWorks. Controller that’s at the end of the chain (furthest from the laptop,) that controller’s “IN” cable has nothing connected to it. Third cable from a controller is power and ground. There are 2 other wires in that cable that did not apply to my install. (Brown wire is for an ECU connection. Yellow is for an analog gauge.) Fourth cable is what connects to the extension cable leading to the O2 sensor. LogWorks software LogWorks was faultless. I say this based on what I dealt with—operating glitches were exclusive to Innovate’s hardware. On some occasions, issues came and went of themselves. Was this LogWorks? I don’t conclude it was but there’s no proof one way or another. I speculate it was the rebooting of the controllers that did this. LogWorks is downloadable from Innovate’s website. Exactly what range of Innovate products LogWorks works with, I don’t know. As I write this, LogWorks is exclusive to Innovate’s own product. Setting LogWorks up calls for a few moments to select fuel type, AFR or Lambda, what port is used for the serial connection, and a few other simple details. All very intuitive given the program’s clear format. There’s more to select if one wants to fiddle with how the software’s digital gauges appear. This visual detailing is not necessary to run the software. If using more than one channel, and with dual O2 sensors, two channels (of the 32 channels available) are used, then a second channel needs to be selected / confirmed during the setup process. With a laptop connected to the controllers… Start the engine, boot Logworks, select the connection, and LogWorks is running and connected to Innovate’s wideband hardware. Data will automatically show in an onscreen gauge once the O2 sensor has reached operating temp. This takes approximately 12 seconds. To see streaming data, it’s necessary to use a drop down menu to open the streaming data window. There are then buttons to start, stop, start a new log, and replay. Traceline colors, displayed time periods (seconds or minutes), and more is selectable in various drop down menus. All very intuitive to navigate. The sensible organization of menus, options provided, ease of operation, and faultless performance of LogWorks = impressive. 10 mpg smoking gun Below are comparison logs for my engine running in its 10 mpg mode, then with an adjustment made to the operating system. Bear in mind this is a 3.2 / Motronic. Warm idle:  10 mpg engine.  Adjusted engine. City:  10 mpg engine.  Adjusted engine. Steady throttle in 4th gear holding 3,000 rpm:  10 mpg engine.  Adjusted engine. Adjustment to the engine was a loaner ECU swapped in for my ECU. To confirm what is revealed by these logs, mpg city was test run with the loaner ECU. Result: 18 mpg. Dean if you happen upon this… again my thanks to you for lending me your ECU! Source of my faulty ECU: Vertex NEVER should a Vertex ECU have entered my 911. But it did. How it did is a twist-of-fate story I won’t get into here. Suffice it to say, I have prior bad ECU experience with Vertex. To plug them further, I’ve purchased an array of bad parts from Vertex over the years. Sometimes they made good. Other times not. My proximity to them has kept (past tense) me going back for more. Suspicion lingered over my ECU. It had been tested while the car and engine diagnosis was in progress to hunt down the 10 mpg issue. “No fault found” led the hunt to continue. Running out of things to test, the loaner ECU was somewhat of a Hail Mary pass—that worked. If a 3.2 experiences ANY fuel related issue, makes sense to swap in a good ECU SOONER than later. Systems Consulting It took Systems Consulting, a Porsche ECU specialist, 310-545-3716, to test my faulty ECU to determine & confirm the error being a corrupted chip. “SC” replaced my Vertex ECU with one of their own. Tested results: 19 mpg city Back to Innovate… My share in this post is a thin slice of what I experienced with my Innovate LC-2 system. Why did I tolerate their glitchy hardware to the extent I did? Simply… data—I had to have it. The time-price I paid to see the otherwise invisible ballet of air & fuel… admittedly steep. My patience for continuing to solve Innovate’s hardware problems… running on fumes now. To be continued... .

__________________

Karl ~~~ Current: '80 Silver Targa w /'85 3.2. 964 cams, SSI, Dansk 2 in 1 out muf, custom fuel feed with spin on filter Prior: '77 Copper 924. '73 Black 914. '74 White Carrera. '79 Silver, Black, Anthracite 930s. |

||

|

|

|

|

Registered

|

2nd to the last straw

This is the connection between the controller and the O2 extension cable working when it wants to. I looked at these connector ends—when Innovate’s product first arrived and immediately after the shipping box was opened. And did so under magnification. Male pins and female receivers, all are poorly made to my eye. There’s also poor alignment of the pins to the extent that these connectors would not mate. This was corrected by adjusting the pins and slightly nudging them into proper alignment, under magnification. We’re talking fractions of a mm. Only after this adjustment would the connectors seat to each other. There’s a fellow on YTube who forced these connectors together and regretted it. I learned from him what not to do. And so the inspection when NEW product first arrived. Last straw At this point, with Systems Consulting’s ECU installed and city mpg what it should be + engine performance stellar across the board… I want to end-stamp the 10 mpg fuel consumption saga with a few final logs. This, for my car’s reference file, also to share with those who, on PPF, provided input and the motivation to keep the project moving forward. And… glitch.In these last two logs below, engine’s 1-2-3 side is magenta. 4-5-6 is black.  Problem here is traced to the controller’s daisy chain. This was found by swapping controllers in their chained sequence. For the log above, engine’s 1-2-3 bank controller is nearest the laptop in the chain. 4-5-6 is farthest in the chain. For the log below, 1-2-3 controller has been moved and is now farthest from the laptop, 4-5-6 controller is nearest the laptop. Tracelines following the position of their respective controller in the daisy chain... where this issue is known. Exactly what the problem is is unknown.  Return the controllers to their original positions in the chain and the tracelines also return to their original positions. Confirmation. Buy another patch cable from Innovate? Not happening. Dump the patch cable and connect the controllers directly? Done. Didn’t work. This issue seems internal to one or possibly both of the controllers. Buy another controller or two to see what happens? Also not happening. Summing up With Systems Consulting’s ECU having solved the 10 mpg puzzle, my enthusiasm to keep Innovate’s hardware running has reached zip. As a result, I have no final logs to end-stamp what amounts to a long—and often mysterious—fuel-related journey. May seem a simple matter that the ECU should have been discovered early on. Situations sometimes have a way of conspiring against simple solutions. That was the case here. The way this 10 mpg journey panned out, testing systems in my car led to finding stuff that needed attention. Fixes were gladly made. From all the component testing done, I now know my 911 better than ever. So, no complaints. As end-stamping goes, given comparable mpg results between my now good ECU and the good loaner ECU, loaner's logs are regarded being appropriate stand-ins. Missing is a WOT log running the loaner. I now regret not doing that. Had I kept a running record of: every Innovate fault experienced, the diagnosis processes applied to each situation, the adjustments made, and time-stamped it all… that roster would prove absurd. Bear in mind this hardware being newly purchased directly from Innovate and just months in service. Nutshelled… LC-2 wideband hardware I bought was:

Innovate’s LogWorks software:

These are the realities I experienced with Innovate. Yours may or may not differ. I only recommend Innovate LC-2 hardware to someone willing to potentially deal with any number of trials & returns, or, someone willing take on whatever hardware issues arise. LogWorks on the other hand is highly recommended… But, the inherent down side here is this software being exclusive to Innovate hardware. Exactly what Innovate hardware I do not know. Certainly their LC-2. End. .

__________________

Karl ~~~ Current: '80 Silver Targa w /'85 3.2. 964 cams, SSI, Dansk 2 in 1 out muf, custom fuel feed with spin on filter Prior: '77 Copper 924. '73 Black 914. '74 White Carrera. '79 Silver, Black, Anthracite 930s. |

||

|

|

|

|

PCA Member since 1988

|

Wow, Karl, that's a fantastic report on what you did. Thank you for that report and your pertinacity in acquiring the data. I'm sure people will be reading this for years to come.

I bought the single sensor AES electronic AFR meter for my car several years ago, and I've often regretted not buying the Innovate 2-channel setup instead, to get readings on both banks of cylinders. However, after reading about your travails with the Innovate hardware, especially the O2 sensors and constant recalibration efforts, I'm now glad I didn't.

__________________

1973.5 911T with RoW 1980 SC CIS stroked to 3.2, 10:1 Mahle Sport p/c's, TBC exhaust ports, M1 cams, SSI's. RSR bushings & adj spring plates, Koni Sports, 21/26mm T-bars, stock swaybars, 16x7 Fuchs w Michelin Pilot Sport A/S 3+, 205/55-16 at all 4 corners. Cars are for driving. If you want art, get something you can hang on the wall! Last edited by PeteKz; 08-23-2025 at 01:12 PM.. |

||

|

|

|

|

Get off my lawn!

|

Wow. Karl, as usual you have a through report. The good news is you have a car with normal mileage after some very extensive and expensive fact finding.

__________________

Glen 49 Year member of the Porsche Club of America 1985 911 Carrera; 2017 Macan 1986 El Camino with Fuel Injected 350 Crate Engine My Motto: I will never be too old to have a happy childhood! |

||

|

|

|

|

|

Registered

|

Amazing and truthful analysis of innovate products, software and support. I believe we touched on this system a while back thru PMs since I had posted my experience with the LM2 system and built out a box to take advantage of all the options available on my CIS Turbo car. Like you say, it either works pretty well or keeps you chasing problems with the hardware and software.

This is still installed in my car but I have little motivation to work with it. I'll blame this on age related laziness and that this whole system was a little over my head to start with. https://forums.pelicanparts.com/911-930-turbo-super-charging-forum/1136267-innovate-lm2-logworks-3-a.html

__________________

Steve 1981 SC Steel Widebody Outlaw in Pacific Blue and Artic White, 930/51 to 3.2l, K27 7006 Turbo, P&P Twin Plug heads, Twinfire Ignition, BLwur, Ruf Intercooler, Powerhaus headers, Zork, CIS Euro FD, 009 injectors, DOD, DP Lid, 044 pump, 930 4 sp LSD, Mocal 44 w/fan, LM2, Brembo, Retroair, Euromeisters. |

||

|

|

|

|

Registered

|

Karl, you are one diligent guy. Your scientific analysis of the problem was the way to go. I wouldn't have thought the ECU was the culprit but through your persistence, the solution was found. Thanks for sticking with it, lots of good knowledge was shared and that's a gem for everyone. The oil companies are sad though.

__________________

1986 Targa Guards Red 2021 MT09 SP |

||

|

|

|

|

Registered

|

Quote:

If you or anyone knows of wideband hardware that there's streaming data software for, be good to know what that option is. Quote:

Quote:

Steve... Yes, I recall our discussing this. Significant wiring you did for your setup. Clean thinking. That you got 6 channels working with your Innovate system... impressive. Keeping it running? Might be the LM-2 is a better made product compared to their LC-2. LM-2 is more expensive. More value...? Sometimes we get what we pay for. Quote:

. -

__________________

Karl ~~~ Current: '80 Silver Targa w /'85 3.2. 964 cams, SSI, Dansk 2 in 1 out muf, custom fuel feed with spin on filter Prior: '77 Copper 924. '73 Black 914. '74 White Carrera. '79 Silver, Black, Anthracite 930s. |

||||

|

|

|

|

Registered

|

Hello Karl,

greets to the sunny state! I’ve done many tests with the LC-2 device from Innovate. There are two points where I’d like to hear your opinion and/or results: Problem #1 – Wideband Output vs. Lambda 1.0 With the factory default wideband output settings from Innovate, Lambda 0.5 is specified at 0 V and Lambda 1.523 at 5 V. Accordingly, 2.45 V should equal Lambda 1.0. If an original Innovate gauge is connected, it indeed shows “AFR 14.7:1” at 2.45 V – which seems correct at first glance. However, in practice 2.45 V does not correspond to Lambda 1.0. Using an officially calibrated test device, I consistently read lower values around Lambda 0.95 at 2.45 V. All wiring and grounding were verified per Innovate’s recommendations. Even Innovate’s own LogWorks software shows this offset: about Lambda 0.95 at 2.45 V. With the LC-2’s simulated narrowband output, however, everything looks correct (0.5 V = Lambda 1.0). So: wiring is fine, sensor is fine – but either the controller outputs an incorrect wideband voltage at Lambda 1.0, or the published transfer values (0 V = 0.5 λ, 5 V = 1.523 λ) are simply wrong. In my DigiECU (for 911 SC lambda-controlled engines – see link in my signature), I can compensate this via a software factor: dividing the wideband voltage reading by 0.95 gives me exactly Lambda 1.0 – but now at 2.58 V, not 2.45 V. This result matches both Innovate’s LogWorks and independent official emission test equipment. Problem #2 – AFR Display vs. Ethanol Content The Innovate gauge shows “14.7:1” at 2.45 V (assuming Lambda 1.0). But as described above, that is not truly Lambda 1.0. In addition, even if the controller were exact, the AFR value of 14.7:1 is only valid for ethanol-free gasoline. With E5 fuel (≈5% ethanol), the stoichiometric AFR is different. The gauge cannot know the actual ethanol content, so at Lambda 1.0 it will always show 14.7:1, even though the real AFR is not 14.7:1.

__________________

911 SC 3.0, 1982, black, US model – with own digital CPU based lambda ECU build and digital MAP based ignition control All you need to know about the 930/16 and 930/07 Lamba based 911 SC US models: https://nineelevenheaven.wordpress.com/english/ |

||

|

|

|

|

PCA Member since 1988

|

^^ that's why I choose to read lambda, rather than AFR, on my AES display.

__________________

1973.5 911T with RoW 1980 SC CIS stroked to 3.2, 10:1 Mahle Sport p/c's, TBC exhaust ports, M1 cams, SSI's. RSR bushings & adj spring plates, Koni Sports, 21/26mm T-bars, stock swaybars, 16x7 Fuchs w Michelin Pilot Sport A/S 3+, 205/55-16 at all 4 corners. Cars are for driving. If you want art, get something you can hang on the wall! |

||

|

|

|

|

Registered

|

Add me to the list who switched from AFR to lambda. With our mandatory up to 10% ethanol fuel, it's a must. Lambda is the real data, not an internal conversion to AFR.

__________________

1986 Targa Guards Red 2021 MT09 SP |

||

|

|

|

|

|

Registered

|

Impressive troubleshooting Karl, wow!

Just to add a (tiny) data point from my own experience: I purchased a brand-new Innovate AFR meter kit when I went to EFI. The sensor burned out a month after it went into use, in spite of always being powered up when installed and used on a running engine. As it happens, that sensor crapped out the day I had booked dyno time. My dyno guy had new AEM meters and new sensors in stock. I installed those, and ran for several years before needing a sensor again. No more Innovate products for me either.

__________________

1981 911SC restomod "Minerva" 2004 Boxster S 2021 Cayman GTS 4.0 manual "Olive" 2014 Cayenne GTS V8 (wife's lover) The slope is not slippery; in fact it is entirely frictionless. |

||

|

|

|

|

Registered

|

Quote:

However, regarding your answer ... even if you select "lambda" readings with the LC-2 device, using the default Innovate voltage settings mentioned above – where 2.45 V should correspond to Lambda 1 – the displayed lambda reading actually will result wrong. In reality, with the factory default settings, a voltage of 2.58 V corresponds to Lambda 1.

__________________

911 SC 3.0, 1982, black, US model – with own digital CPU based lambda ECU build and digital MAP based ignition control All you need to know about the 930/16 and 930/07 Lamba based 911 SC US models: https://nineelevenheaven.wordpress.com/english/ |

||

|

|

|

|

Registered

|

Quote:

From my Innovate experience, I'm not surprised with ANY anomaly that ANY user now makes note of, you now included. Quality is not in the hardware as I received it. Apparently not yours either. From my Innovate experience, I'm not surprised with ANY anomaly that ANY user now makes note of, you now included. Quality is not in the hardware as I received it. Apparently not yours either.In LogWorks, there is the option to view data as either AFR or Lambda and to select a fuel type. I made these selections choosing Lambda and gasoline. I vaguely recall voltage options but I made no selection in this regard as I concluded there being no need. I do understand what you are saying about the voltage and what may come of this if they are not working correctly. Given what I saw when my LC-2 system was generating good data, and based on my tested mpg results---both bad mpg and finally good mpg---my Lambda readings corresponded to the engine's fuel use as I saw it. In other words, I believed the Lambda values were correct. If my system was currently working, I'd check the voltages to compare notes with you. I think you know I'm done with Innovate. .

__________________

Karl ~~~ Current: '80 Silver Targa w /'85 3.2. 964 cams, SSI, Dansk 2 in 1 out muf, custom fuel feed with spin on filter Prior: '77 Copper 924. '73 Black 914. '74 White Carrera. '79 Silver, Black, Anthracite 930s. |

||

|

|

|