|

|

|

|

|

|

|

|

|

|

|

Kartoffelkopf

|

Mostly lathe work this evening, making 4x "things" (at a loss as to what to call them...) that mount onto the studs of the exhaust valve cover, onto which I'll weld the framework to hold the water radiator.

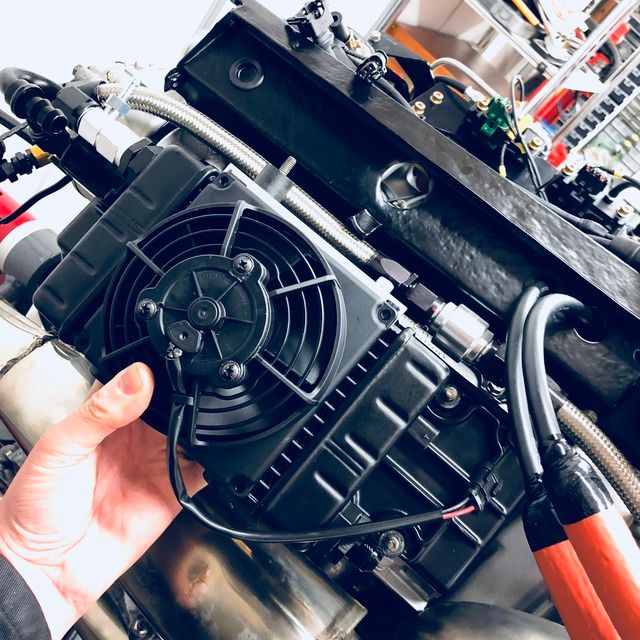

The plan is to (probably) use just 1 pillar/tube on the top mounting, with a pair of struts coming from it and across onto the 2x top mounts on the radiator. Depending on how rigid that turns out to be, I'll either repeat and mirror for the lower mounts, or if I want something stronger to take the weight, then I'll use a pair of mounts, with a strut from each. Here you can see my thinking, with one of the "things" onto a top stud. So long as the furthest point of the 180º hose joint doesn't protrude past the back of the scavenge pump, I reckon it'll be fine when installed. If anyone knows better, please shout now before I weld anything....This hose is the hot side inlet to the radiator, with a bleed hose returning back up through the tinware to the expansion header tank. This bleed junction, is *just about* the highest point in the circuit and also the furthest point from where the header tank feeds into the loop.   The 4" fan will mount on the outermost side, pulling air through the radiator, which is more efficient than blowing air into it.  A quick layout of what-fits-where, I'm just waiting for the -8 Female-Female coupling joint to hook up the T and another 180º fitting onto what will be the radiator outlet. The pump will mount alongside pulling water up and out across to the turbo. The 180º fitting will be where the header tank feeds into the system, again coming through from the top side of the engine via the tinware. Finally, it's another case of "you wouldn't believe how long it took me to make a bracket"....  One of the fan mounting brackets, absolutely spot-on dimensionally. Hoping #2 won't take as long, now I can take dimensions from the first one. Four clinch studs pressed in from the underside will be used to mount the fan. Need something with a very shallow head to avoid contact with the radiator core. These will be pressed in once the brackets have been anodised. Rubber bobbins are in the post; I'm using the type with a female thread on one side rather than the one shown above with two male threads. A few jobs to now do; I need to make a -8 Male-Male union with a 1/8" NPT thread inbetween, so I can install a water temp sender. I have 2x weld on -8 fittings, I just need to make the centre section, with a large enough diameter to accommodate the 20mm (or so) depth of the sender, without impeding water flow. I also need to make two -8 > 3/4" pipe fittings, to interface the pump to the rest of the water circuit. A couple of pretty easy jobs for one evening this week. |

||

|

|

|

|

Kartoffelkopf

|

Plenty of progress over the last month, albeit sporadic whilst waiting for parts to arrive and having spare time to do it.

Following on from the previous update...

So...a few evenings and weekends spent making the individual components needed for interfacing the Bosch water pump (push-on hose fittings) into the rest of the system, of course using -8 AN fittings. In addition, all the parts needed for making the expansion tank were completed just in time for me to get across to my pals for them to weld. The 2x adapters.....  The water temp sensor housing....    This Bosch sensor of course needs to be spaced out of the way in this application, with the probe tip being about 20mm long I need to get it in a position that water can flow up around it, but for it not to obstruct the water flow in the small bore of -8 fittings. It uses an M12 thread, but the tapping drill for the M12 still didn't (in my opinion) allow enough fluid flow around the sensor, so I taper bored the ID of the bottom of this housing to open it up; worked a treat. The lower section of this piece was then milled flat to allow the pair of -8 fittings to be welded on. I've now tidied up the welding to a degree, but I'm not going to go overboard for fear of compromising the joints water-tightness. All these fittings will be anodised once I've finished trial fitting everything. The expansion tank.....    This has an angled base, to clear the large wiring harness which runs underneath it along the chassis rail to the engine bay fuse box and relay assembly. I've added a pair of 1/8" NPT lugs so that I can install a sight gauge with a pair of 90º fittings. I need to order these on Monday, along with a 45º or 90º -8 fitting for the tank outlet. Tonights job is to smooth out the welds on the base and the top of the tank (like I did for the oil breather tank), in readiness for it being powder coated next week. The mounting bracket will re-use two M6 fittings that were originally used for the old CIS fuel system, latterly used for my old ignition amplifier mountings. The biggest leap forward was yesterday evening, with my pal Lewis coming over with his Migatronics TiG rig (...which I'm still trying to twist his arm into selling to me...), so that we could weld the mounting brackets for the radiator in-situ. As always, the first one's always the hardest, where you need another couple of pairs of hands, and unnatural levels of dexterity to hold everything straight-and-level. Once the first arm was tacked onto that first spigot, and the rubber bobbin plates cut to a sensible length, then it all became a lot easier. I have to say, very happy indeed with how it's looking. None of the arms block access to the M8 nuts for the valve cover, there's plenty of space between the radiator and the ignition coils, so I'm hoping to run one of the hoses behind the radiator. We decided to allocate 1x spigot per arm, rather than siamesing a single spigot for the top, and another for the bottom. I think the mass of the setup, plus a decent amount of fluid, would've put too much load onto the arms if done like that.

|

||

|

|

|

|

Kartoffelkopf

|

Next job was to make a similar assembly to support the water pump. Some guesstimation required here, as the stainless "P" band I've made for the pump wasn't quite finished. As you can see, it's turned out nice, and very sturdy indeed.

I did consider whether both of these jobs could be done over in Lewis' workshop using an ally plate for a jig to mount the valve cover onto. Very simply, "not a chance". Setting the radiator at a height where the return hose bleed line is higher than the centre housing of the turbo was critical, as well as missing the wastegate hoses and mounting it correctly relative to the back of the engine (scavenge pump). Maybe possible with lots of trips back and forth, and that likely would've taken a couple of weekends of Saturday mornings to get it right. Far easier that we traded an evening of his welding, for a day of my help with his Escort Mk2 restoration project! In terms of the wiring harness, a days vacation last week enabled me to get across to Simons workshop so that we didn't have to try and rush it on a Saturday morning. We needed to add a switched 12v supply that I can then use with a 12v > 5v converter which will power the WiFi router. A CAN bus connection for the lateral G sensor also got missed off previously, but easily added. The biggest additions, however, were to accommodate the water cooling circuit. I was concerned that we had perhaps used all of the inputs/outputs of the ECU, and that I'd have to resort to using a standalone fan controller circuit. Perhaps perfectly good, but a little crude. As it happens, we did just about have enough to allow a temp sensor input, along with direct drive outputs for the fan and the water pump. The outputs from the ECU are suitably spec'd for this loading (we bench tested both the fan and the pump current loading, sustained and initial surge at switch-on). So, lots more we can now control from the Syvecs. Finally, the TurboKraft turbine cover is now installed and tidies up the turbo no-end. Looks very smart. Because of the fittings I'm using to flow water into the CHRA (-8 banjo), I had to skinny-down the hex bolt adjacent to the water port, so that now clears by a gnats todger.  Some final tidying up of the water radiator mountings and they're ready to go for powdercoating. Another consignment to the plating shop, and then (probably) a fortnights wait until I can reassemble it again. And then I think we're very close to getting the engine back in the car.....but don't hold your breath... |

||

|

|

|

|

Kartoffelkopf

|

I almost forgot, I've FINALLY got the headlamps back together again!!

I was struggling to get the painted trim rings sitting nicely over the black "technical" rim which holds and aligns the lamp unit. I couldn't work out why, even after stripping the black powdercoating back off, it wasn't going over. I'd assumed to start with that the powdercoat finish was marginally too thick but upon closer inspection, it looks as though some distortion has taken place when they were being prepped for coating. My suspicion is that they were incinerated to get the old black painted finish removed; when I looked closely at the shallow lip that wraps over the glass, it had distorted enough to make a difference. So, two choices....persevere with gently manipulating it back into a shape that works, then send it off for painting or black electroplating. Plating would mean that I would need to spend a decent amount of time removing the bead-blasted finish and polishing it, with a risk of distorting it again. Or....use the best tool in the toolbox; that lovely piece of plastic, approx 2"x3" and cough up the reddies to Porsche for a new pair. £185 the pair!!! They did come with new lamp adjustment screws, and new trim ring screws which I wasn't expecting....but still, that's a fair chunk of wedge for two metal rings, stamped out in the thousands in a factory somewhere.  Next job was to then repair the tabs in the headlight bowls, where the M5 thread had "pulled". Helicoils and a Dremel to shorten them, then a nice coat of paint to recoat where it had cracked and flaked off....if it's worth doing, then it's worth doing right.... An hour spent rebuilding the pair of lamp units with the retainer spring clips, and they fit like a dream...albeit with reassuring persuasion from the heel of my hand...the "percussion method" (you hit it). She's got her eyes back! It's been 4-5 years since I've seen the car with the trim rings on, last time it was driving it was with the black rims....

|

||

|

|

|

|

Registered

|

Hello Spencer, that made for a long time that I saw no more news on your comment, I began to worry! That was worth waiting, great and magnificent work Spencer!

|

||

|

|

|

|

Kartoffelkopf

|

Quote:

....the projects "CMO" (Chief Motivation Officer) ....the projects "CMO" (Chief Motivation Officer)

|

||

|

|

|

|

Registered

|

|||

|

|

|

|

Registered

|

How to describe this project? C'est pas possible! Just nutty in a lovely way, maybe ultimate expression of "man in shed builds next Concorde"? The mounting legs for the heat exchangers are sublime. Or maybe I should just say "Gosh!" Kind regards, John.

|

||

|

|

|

|

Kartoffelkopf

|

Haha! Thanks John, appreciate it! Love my "shed", can't imagine being without it now - once the engine's done, time to investigate a proper mill. Talking about Concorde, one of the (very few) regrets I have is not booking a ticket on one of Concordes final flights....

|

||

|

|

|

|

Registered

|

Spenny, I'm originally from Bristol and my Dad worked at Rolls-Royce (nee Bristol, nee Bristol-Siddley), so we were raised on a diet of Concorde-obsession (and Harrier, Tornado, Vulcan, etc). We were at Patchway for the first flight of the first Bristol-assembled Concorde; from the playing fields at primary school we used to see RR's Vulcan Mk1 test bed (for the RB199 Tornado engine) flying overhead. We thought all this was normal.

I never flew on it but my Dad did once. When my parents retired near Kingston, on the approach to LHR, they'd leap to their feet everyday around 5pm to get a good look when the BA Concorde arrived from JFK....who wouldn't? Best hot-rod ever, NEVER got old seeing it. I flew into LHR a couple of weeks ago and saw BA's remaining example sitting on the apron to greet all arriving 'planes. Your engine project is insanely obsessive, in the very best of ways. Best to you Sir. |

||

|

|

|

|

Kartoffelkopf

|

Oh wow! What a diet of cracking aviation experiences. My other regret was not even investigating a career in the RAF when leaving school. No idea why not, would love to have been into the engineering side, but strangely don't have *that* much of a desire to actually fly myself. Although a colleague of mine has his PPL and often twists my arm to give it a go...maybe one day.

When I first joined IBM, I used to travel from Stevenage to Weybridge every day. I remember one journey during the summer, sunroof open, stationary on the M25 by the Heathrow junctions (whod've thunk it) and all of a sudden Concorde took off directly overhead; I hadn't seen it coming from my left, think "that scene from Top Gun" when they buzz the tower...looking through the sunroof to see it directly overhead, simply amazing, and then seeing all 4 Olympus engines billowing a lovely quartet of exhaust twisties out the back as it carried on to my right. We used to set our watches in the Weybridge office when we heard the window frames rattling. Happy days. ETA: I was lucky enough to see Vulcan (XH558) flying over my house twice; once when the re-launched Manston air show took place some years ago, then again on it's final circuit of the UK. Seeing that delta shaped shadow looming over the garden was, er, "weird"! What made it stranger was that a few hours previously, the Orient Express had gone through (as it does occasionally) at the bottom of my garden...Planes, Trains...I was just waiting for the Automobile bit, lol. If you're on Instagram, look up a guy called Carl Evans, @GasGasBones ....ex RAF guy now making watches/watch straps/steam engines (!)/laser watch engravings...he quite often posts interesting stories of his experiences. Saw one last week of a 4 part video from a 90's TV documentary following one of his pilot buddies, buzzing through the Scottish Highlands where he was based at the time. Last edited by Spenny_b; 02-27-2018 at 04:41 PM.. |

||

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

The add-ons will continue until you run out of room in the engine compartment!

(That didn't stop Porsche however. . . the 3,3 turbo tail replaced the 75 Turbo version due to precisely that frustration  ) )So you are cooling the Turbocharger. Forgive me, is that primarily for longevity or charge temps? Or is it really both? GREAT updates and the H4 interlude is a nice reminder that the CAR is evolving too! Carry on!

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

|

Kartoffelkopf

|

Quote:

Re the turbocharger, this is me being a little overkill/paranoid. Anyone that's followed this build will appreciate that I've not had the most straightforward of runs with this build. I'm sure no worse than most, but at times it's very much been me ruing my crappy luck, "if it can go wrong, it will". I know damn well that Chris is sitting in Arizona, shouting at his laptop that I'm over thinking the whole thing on the basis that GT35R's are working perfectly well "in the wild" without any water cooling but with the cooling ports left open, with only the oil supply to the centre bearing. Sorry Chris, you know better than most that me being OTT is business as usual   Two things prompted me to revisit the idea of water cooling. Firstly there's a thread over in the Turbo/Supercharging forum where somebody has built an experimental water cooling setup to test the theory, monitoring the temp drops when activating the water pump after engine shutdown. A lot of heat is being pulled out of the CHRA, which can only be a good thing? Secondly, reading the Garrett whitepaper on water cooling their watercooled turbos, and seeing the carnage that can occur with coked oil on the shaft/seals, resulting in snapped shafts (and then the ensuing compressor carnage, potentially up in to the intercooler and beyond if really unlucky)...I certainly didn't want to be that show'n'tell case where everyone looks in amazement and ponders the situation proclaiming that they've never seen it happen before, whilst I have another rebuild at HUGE expense to put right. In my mind, better to invest a decent amount of time and a lot less money, putting a solution in place that mitigates the risk, to the best of my abilities. If it still goes bang after that, then I can at least rest easy knowing I did everything I could, and not have smart-arses telling me "told you so....Garrett DO say to watercool (you idiot)" If we get the intake temps down as a secondary benefit, then great, but Chris's intercooler was doing a fantastic job of that when we ran it in the dyno cell - perhaps not a lot to be gained there in terms of hp/torque...but we'll see. |

||

|

|

|

|

Registered

Join Date: Feb 2016

Posts: 360

|

It is amazing what can be done when you put your mind to it.I cannot stop looking at your motor it's soo good.Have you already tested watercooling your turbo?

Sent from my SM-N950U using Tapatalk |

||

|

|

|

|

Kartoffelkopf

|

Quote:

No, I've not yet tested anything. I got as far as plumbing in a lot of the engine-side hoses on Build #1 about 4yrs ago, but in an effort to just get the car up and running, I deferred the water project until I had something which was mapped and drivable. In terms of testing the effectiveness of water cooling the CHRA, it was Brad ("turbobrat930") who re-started my interest in doing this, in this thread over in the Turbo/Supercharging forum Says Brad >>> "Its CRAZY just how much heat this setup pulls off the CHRA after shutdown!! I have it set to run for around 10 minutes or so, after shutdown. When it first is turned on, it is a good 180 to 220 deg air coming out. After 7 to 10 minutes, it is right about ambient. Hope this helps anyone else that wants to do something like this." I'm going to test the pump on its own to ensure it can "lift" fluid in the configuration I have. Once the engine is spun around again to the horizontal, the pumps orientation won't actually be a 4" high vertical lift, more like 45º. Think Automotive are currently reaching out to their vendors to ask the question, as strictly speaking this is defined as a circulation pump, not a lift pump - it *may* require some alterations in pump position, we'll see. Then the plan is to rig up the system once everything is plumbed, and pump water through it before putting the engine back in the car; check for leaks etc. My implemention for the cooling strategy is slightly different to Brads; rather than powering the fan/pump after engine shutdown to alleviate the coking of the stationary oil, I've got my setup hooked into the ECU, so we'll actively monitor the temperatures and power the pump/fan to cool the water once temps dictate we need to, whilst the car is driving. We can then keep the pump circulating after shutdown, if required. |

||

|

|

|

|

Registered

Join Date: Feb 2016

Posts: 360

|

Spenny,Please hurry up.Haha.I am almost out of popcorn.I would love to duplicate or try to with my new soon to be set up.I am now inspired...

Sent from my SM-N950U using Tapatalk |

||

|

|

|

|

Registered

Join Date: Feb 2016

Posts: 360

|

What do you think about running a/c through the intercooler?

Sent from my SM-N950U using Tapatalk |

||

|

|

|

|

Kartoffelkopf

|

Quote:

?? Sorry, you've lost me there Kevin?.... |

||

|

|

|

|

|

Registered

Join Date: Feb 2016

Posts: 360

|

On the newer 911 turbo cars they have launch control and I believe one of the ways they can lau inch the car over and over is they plumb some of the turbo piping through a boxed a/c condencor.I always wondered if some how you could run into or onto the intercooler or charge pipe if it would help with all the heat that our turbo car create,or maybe some things are best kept to ourselves.Haha

Sent from my SM-N950U using Tapatalk |

||

|

|

|

|

Kartoffelkopf

|

Ahh, I see...hmm, not heard of that on the newer kettle (watercooled) turbo cars. Would be a helluva piping nightmare, as the AC condensors/evaporators are at the front!

Nah, Chris's intercooler delivered some truly eyebrow raising AirT numbers during that week in the dyno cell....even the wisened operator guy was mightily impressed. (K.I.S.S.)

|

||

|

|

|

|

|

|

| Tags |

| 964 c4/c2/turbo , efi conversion , life racing , syvecs , turbokraft |