|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

sorry. double-post

__________________

1975 911 2.7 Coupe Last edited by declang; 03-27-2008 at 02:08 PM.. Reason: double post |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

Ack, I posted a big long reply here and I'm sure it appeared but its gone now

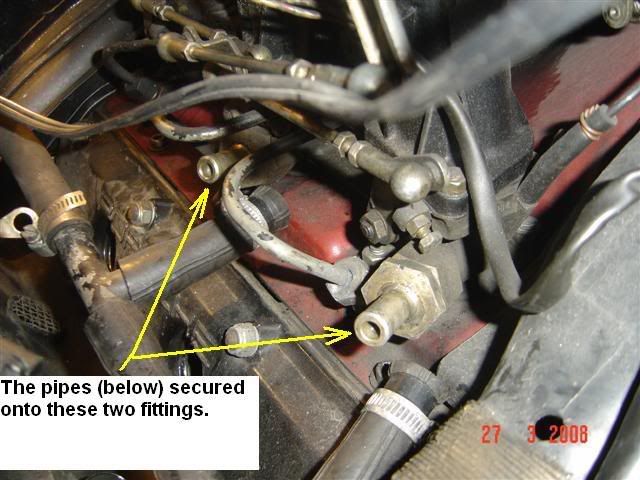

Basically, what I was saying was that I can't locate a Z-block here to measure the cams, so I'm going to order from our host  Also going with an LM-1 & rpm to help with my adjustments. Also going with an LM-1 & rpm to help with my adjustments.I decided to have a look at plug leads and in the process I noticed some other screened cables and "something" all taped up.  I found the screened cables were from coil & points back to CD unit. The "big taped up thing" had me puzzled. Some mysterious porsche technology I knew nothing about ? I got the cable assembly out  untaped it  untaped some more  and ended up with this  Crazy ! Is there any need for screening of these cables ? I noticed an unscreened cable from the CD unit spade connector over to the fan housing, earthed with the same earths from the other screened flexes. Does that make any sense ? Any reason for that ? Staying on electrics, there is a push-button switch on that electrical panel, with a figure-of-eight cable (like thick speaker cable) that disappears off into the body work on the right hand side. What is the switch for ?  Lastly, there is a largish pipe which comes from two fittings on the throttle bodies for cylinders 1 & 2. I didn't trace the other end of the pipe. What is it ? Vacuum ? Why such large pipes ?  Thanks. Declan

__________________

1975 911 2.7 Coupe |

||

|

|

|

|

Registered

Join Date: Dec 2003

Location: Arapahoe County, Colorado, USA

Posts: 9,032

|

Declan,

OK, I can answer some of your questions. The plumbing at the #1 & #2 intakes is originally for a Sportomatic transmission. Do you have a Sportomatic? Occasionally these vacuum ports are used for the ‘power brakes’ but those start in ’77 and aren’t normally on a ’75. Is the vacuum system hooked to anything? If not, we need to plug the ports in the throttle bodies. If those vacuum check valve ports are open to the atmosphere, I think we found the source of the ‘popping’. They are drawing air at idle, causing #1 & #2 cylinders to be exceeding lean – thus lean pop. If this is the case, I suspect you will find only #1 & #2 cylinders popping through the intake. This also skews the overall mixture readings. Two cylinders are very lean and the other four are too rich. First plug the air flow to these two check valves. I’ll bet the ‘pop’ stops and the mixture settles down – still too rich. This may be the ‘big deal’. I’m somewhat surprised at the length of the harness to the CDI. I wouldn’t be surprised to find this was a harness for some other car. The shielded wires are necessary for Radio Frequency Interference (RFI) suppression. The 3-pin Bosch CDI has very fast risetime. Porsche (and Bosch) did this to overcome plug fowling. Fast risetime translates (with Fourier expansion) into very high (radio) frequencies. The braided shielding is to prevent interference with nearby radios, including the one in the 911. This RFI can even self-induce the CDI to fire multiple times. Please post images of the other braided cable from the CDI box ground to the fan housing. This may be an attempt to reduce RFI. It is useful to check some other grounds (‘earth’ connections). Is the braided ground strap between the transmission and chassis in place? Is there a braded ground strap between the CDI and the ground connection on the left inner fender (behind the CDI)? Regarding the wiring, the ignition pulse from the CDI box to the ignition transformer (‘coil’) is about 400 V! There used to be a warning decal on the ‘coil’. Touch the lead and it will knock you across the room or worse. The push button switch on the electrical relay panel is not OE Porsche. I suspect it operates the starter or something in the cold start circuit. Follow the wires. When your MFI is adjusted correctly, you will need the cold start enrichment to easily start at anything below about 70F. Without it you should not be able to start it at 42F. This is an indication as to how rich it presently is operating. Change the oil. Smell the petrol in the oil!   Best, Grady

__________________

ANSWER PRICE LIST (as seen in someone's shop) Answers - - - - - - - - - - - - - - - - $0.75 Answers (requiring thought) - - - - $1.25 Answers (correct) - - - - - - - - - - $12.50 |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

Thanks Grady,

I do have servo assisted brakes. The rubber pipe from these disappears off into the body from the engine bay, haven't looked for the other end yet, but I guess its vacuum for the brake servo. Edit: Confirmed. Pipe does go all the way to the front to the brake servo  Quote:

I guess I just shorten those two cables to required length. The other ground cable from CDI unit to fan housing is a simple violet/black flex, I'd guess about AWG18. No screening, and not routed with the other screend cables. (see pic)  I have not yet checked for braided starp from transmission to chassis Will check this evening. Any pointers on where exactly this should be ? There is a braided ground strap between the CDI and the ground connection on the left inner fender (behind the CDI) Quote:

One of the 2 wires to that switch wire is off. Perhaps it broke off while I was manhandling the unit to remove it, but I'm not sure. Will trace & report back. Thanks again for the input. It is very much appreciated. edit: Just a thought, I do have a "gunson gastester professional". Can I use that for dwell & tach readings ? The instruction manual says not to be used with CD systems ? Cheers, Declan

__________________

1975 911 2.7 Coupe Last edited by declang; 03-28-2008 at 11:59 AM.. Reason: Added more info |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

further digging today ....

I checked the length of the link to the mfi pump. exactly 114mm centre to centre, so thats good. I have a problem where the throttle linkage does not fully return to the off position. It returns almost fully, but not enough to operate the microswitch. I disconnected the two links to the throttle bodies and checked them for binding, but all seems free.  I removed the throttle cable link also, and it seems very free to move by hand. The deflection roller seems free enough to move, no binding, but the end of the helical (?) spring seems to pop out of its holder very easily, so there is no return effect at all. Even with the spring reseated properly, it's enough to move the deflection roller back to rest, but not enough to operate the microswitch. - Should it be enough pressure to operate the switch ? I did try getting one more turn on the spring, but the end just pops out of the hole again when you move the deflection roller.  I noticed there is space for a second spring on the right hand side of the deflection roller, but none is there, which seems correct  Slainte, Declan

__________________

1975 911 2.7 Coupe |

||

|

|

|

|

Max Sluiter

|

I think you need a new spring to really fix this problem.

My spring was strong enough but the microswitch was not being triggered by the retuned trottle arm. I tested the switch with a volt/ohm-meter and it functioned electrically. I could hear it working mechanically so all I had to do was to adjust the screw which contacts the microswitch button. It is located on the end of the throttle arm. In a similar way to adjusting the valves, screw in the adjesting screw on the throttle arm. This will make contact with the button earlier and put the arm in a position where it recieves more force from the spring, solving the problem. If the microswitch does not read infinate resistance when open and near zero when closed, the switch is bad. You can pick up a suitable replacement from Radioshack or Newark Electronics or similar electronic parts suppliers. Don't go to the dealer  It wll cost 8 times as much. Just take the switch into the local Radioshack and tell them you need one of these. It wll cost 8 times as much. Just take the switch into the local Radioshack and tell them you need one of these.Edit: I don't have a spring on the passenger side of the throttle crossover linkage, either. Hope this helps

__________________

1971 911S, 2.7RS spec MFI engine, suspension mods, lightened Suspension by Rebel Racing, Serviced by TLG Auto, Brakes by PMB Performance |

||

|

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

Yes, Flieger, thats want I needed to know. Thanks.

__________________

1975 911 2.7 Coupe |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

And another thing .....

(should I just continue posting in this thread, instead of starting new threads ?) I decided to have a look at the throttle bodies, so started trying to remove the right side. Got the stacks off but ran into a problem trying to take the pipes off the injectors. I cant budge them. I presume they are a "normal" thread ? (clockwise tighten, anticlockwise loosen ?) I did get a good look at the butterflies and the underside of all 3 are very dirty. (Pics below) I guess I need to persevere & get them off for cleaning ? They do move freely, no binding, no sticking closed, so at least thats something. I did notice, however, the spring on #5 is not as strong as the other two springs. It does close the butterfly, but not with the same force as #4 or #6   Stamped on the throttle body, closest to me, (#4?) is the code : 02 73 257 On a separate note, while following the vacuum pipe to the brake servo up front, I noticed a bunch of wiring with two multipole connectors laying loose in behind the servo. I'm guessing its from an older alarm/immobilizer install, but the connectors seem quite an old style. anyone recognise them ?  Slainte, Declan

__________________

1975 911 2.7 Coupe Last edited by declang; 03-29-2008 at 09:03 AM.. Reason: removed blurry pic |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

OK, Today I persevered, and managed to get the pipes off the injectors, and the throttle bodies off one side (4,5,6).

They are (it is ?) very dirty, and will take a lot of cleaning. I Measured all 3 at around 37mm. mabye a point or 2 more edit : more like 36mm, see later posts ... (battery gone in my digital vernier !)

__________________

1975 911 2.7 Coupe Last edited by declang; 04-01-2008 at 10:51 AM.. Reason: measurements |

||

|

|

|

|

Registered

Join Date: Apr 2000

Location: Kansas City

Posts: 1,675

|

Did we ever get the serial number for this engine? 37mm+ MFI throttle bodies sound interesting....

JA

__________________

John - '70/73 RS Spec Coupe (Sold) - '04 GT3 (Sold) |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

the original engine was 911/41

This is stamped on the casing, near the oil pressure sender, and matches the engine serial number. It was rebuilt, adding the MFI supposedly to "RS Spec", but I'm unsure what work was done. edit: I measure the TB's again. 37.x at the top, but only 35.x at the bottom. The ports on that they mate to are 37.x edit: nope. more like 36mm ! edit2 : I found this thread MFI Induction Chart which gives the ID of the various parts of the intake system. But, I cannot match my measurements to any of them. I seem to have :Top opening of throttle body = 37.x (mabye 38mm at a push) Bottom opening of throttle body = 35.x mm Cylinder intake port. = 36 mm Closest match I can find would be the S setup, with 38, 36, 36. There is quite a build of carbon in the TB's, enough that can be scraped off, but I doubt it would add up to 3mm on diameter. Mabye 1mm worst case, making it close to 36mm. edit3: I measured and measured and measured. I'm pretty sure the setup I have is 38,36,36 from top of TB, Bottom of TB & intake port. I must have been measuring the intake port gasket, and not the port itself when I got 37.x !

__________________

1975 911 2.7 Coupe Last edited by declang; 04-01-2008 at 10:50 AM.. Reason: wrong measurements |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

nothing much to report yet. still cleaning the throttle bodies !

__________________

1975 911 2.7 Coupe |

||

|

|

|

|

|

Registered

Join Date: Mar 2004

Location: Higgs Field

Posts: 22,755

|

The main throttle return spring is the one on the pump itself. It is quite a stiff spring and, if it is not returning the whole works to the idle position, none of the other springs will, either. The one spring on the rack and the six on each butterfly are very weak, and are only really meant to take the slop out of the system that is inevitable with all those ball cups, pivots, and such. They are not meant to, and will not overcome any binding in the rack or throttles.

All throttle bodies are tapered top to bottom. You have the standard S/RS sizes. It's looking more and more like your motor was properly converted to an RS spec 2.7. That's good news. Looking at the state of those butterflies, it's a minor miracle it ran at all. If they are that carboned up, the air bleed ports are probably all but shut. Soak those things in some Berryman's for a week or two to break up all the carbon. Don't stop cleaning until they are well and truly clean. Keep at it until the bypass passages are open and the butterflies move freely. That will solve a lot of your problems. Make sure all of the stops are adjusted properly as well. The closing spring pressure should not be taken up by the butterfly resting on the side of the bore. They do have to fully close, but that is different than bearing on the bodies under spring pressure. If they do, they will soon wear grooves into the soft metal of the throttle bodies. Then they're toast. Anyway, unhook all of the short linkages so each butterfly will move on its own. Back off the stop screws until the butterflies rest, when closed, on the bores. Then turn the screws in just enough to take the spring pressure; you don't want the butterflies to move. You should be able to hold them up to a stong light and not see any light around the butterflies when you are done. Set the two short rods (from the center #2 and #5 to the fore and aft #1, #4, #3, and #6) so there is no preload with all of the butterflies shut. When you put them back on the motor, you want no preload in the rods to the rack. With the rack to pump rod at the specified length, you should be able to hook up the two rods to the throttles without having anything move. Keep adjusting them until you get them right. They don't have to be the same length; CMA specifies a pretty broad tolerance on them to achieve correlation. By doing all of this in the manner I just described, you have achieved correlation per a later service bulletin that Porsche issued as a supplement to CMA. This is how it can be done without the protractors. So, in essence, when it's all back together you are looking for a few key things. The pump is on its idle stop. The throttles are on theirs. The pump to rack rod is the specified length. There is no preload anywhere; all rods can be connected and disconnected without anything moving. Then, and only then, will you be ready to start adjusting bypass screws for synchronization. Then, and only then, will you be ready to start turning screws in the pump to set part load and idle mix. You're actually pretty close now; eliminating the crud will make everything else fall into place quite easily.

__________________

Jeff '72 911T 3.0 MFI '93 Ducati 900 Super Sport "God invented whiskey so the Irish wouldn't rule the world" |

||

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

Declan,

I would soak the throttle bodies in B-12 chemtool, or whatever the Irish equivalent of nasty, smelly carburetor cleaner is. Carbon in the air correction tubes or on the throttle plates will prevent you from achieving perfect correlation. Here's my take on the subject, you may have already read this. The MFI Diaries: Correlation at LAST! A little motivation when you are cleaning your throttle bodies. . .      p.s. Higgins what county you from with a signature line like that?

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

Registered

Join Date: Mar 2004

Location: Higgs Field

Posts: 22,755

|

Geez John, "motivation" or a crushing feeling of inadequacy?

Those are almost pornographic to a guy like me... Those are almost pornographic to a guy like me...The Higgins family hails from County Sligo, so not too far at all from our friend declang.

__________________

Jeff '72 911T 3.0 MFI '93 Ducati 900 Super Sport "God invented whiskey so the Irish wouldn't rule the world" |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

I'm sobbing in my Guinness looking at those "what it should look like" shots. Wow.

Yep. Sligo is only 70 miles from me.

__________________

1975 911 2.7 Coupe |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

I can't locate any berryman stuff over here, or anything similar for steeping them in.

Had a go today with some brake cleaner fluid & it seems to do the trick with a bit of toothbrush scrubbing. Guess I'll be a while at this stage !

__________________

1975 911 2.7 Coupe |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

Well, after a lot of scrubbing & spraying, I've got them clean.

Took a lot of scrubbing with a toothbrush & some brake/clutch cleaner.

__________________

1975 911 2.7 Coupe Last edited by declang; 04-06-2008 at 01:16 PM.. |

||

|

|

|

|

Registered

Join Date: Mar 2004

Location: Higgs Field

Posts: 22,755

|

Wow, what a difference. Good job. With the same kind of care and diligence applied to setting them up, you will be well on your way to MFI happiness.

__________________

Jeff '72 911T 3.0 MFI '93 Ducati 900 Super Sport "God invented whiskey so the Irish wouldn't rule the world" |

||

|

|

|

|

Registered

Join Date: Dec 2004

Location: Donegal, Ireland

Posts: 159

|

Thanks for the words of encouragement Jeff

__________________

1975 911 2.7 Coupe |

||

|

|

|