|

|

|

|

|

|

|

|

|

|

|

Registered

|

Hi spencer, I cross fingers for the next weekend!

|

||

|

|

|

|

Kartoffelkopf

|

Steady progress through the week in preparation for this weekends activities.

Great evenings work tonight; most important thing was to get the oil circuit primed and make sure we have no leaks. And that we get oil pressure, of course. Removal of the lower plugs in order to give the starter motor an easier time, and then a video call into Chris, who very kindly witnessed the first cranking of the motor, live from Blighty. It's a good job he warned me that it will take a good 20-25secs of cranking (2x 15sec pulls, no longer), to get the oil pressure needle off the bottom of the gauge; I know I've done this before, but paranoia is at play, and knowing that the time it's taking to get oil pressure up was very reassuring. Great news, we have just under 2bar of pressure at (faster than usual) cranking speed. A thorough check under the engine and in the engine bay, and I can't see any leaks. Looking good, but not counting my chickens just yet. Next job, to fill the water cooling system. Good news there as well, no leaks! Again, I'm not home and dry yet; coolant has only filled as far as the electric pump, including the cooling matrix, but there's quite a few joints that are now "wet", so pretty happy that it's not weeping from anywhere. The plan for the weekend has changed a little; Simon (wiring) is now coming along tomorrow to perform a systems check, make sure we can see all the sensors, etc. Sam is still coming along on Sunday to build a base fire-up map, start the engine and do some "snagging", make sure there aren't any silly problems before we book dates on the dyno. It's moving along... |

||

|

|

|

|

Kartoffelkopf

|

|||

|

|

|

|

Registered

|

|||

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

Kartoffelkopf

|

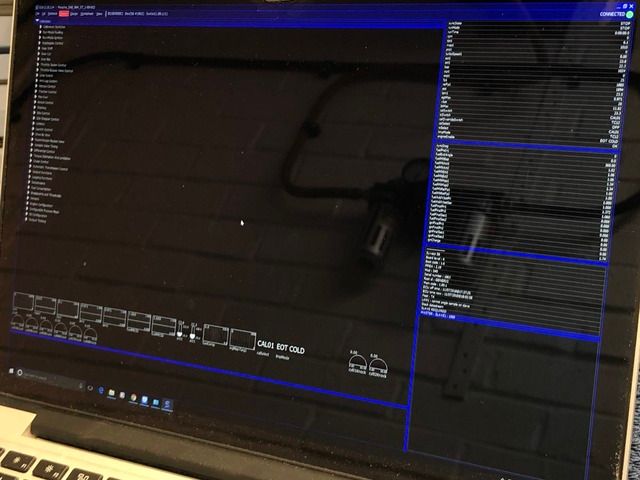

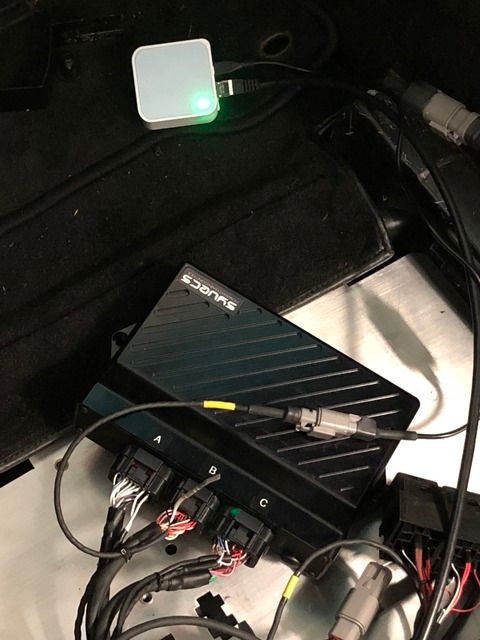

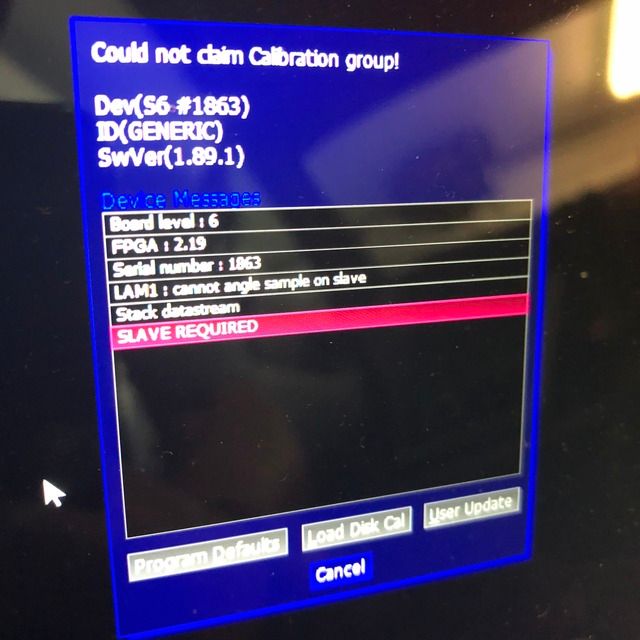

^^^ Not quite, as it turned out. Although your new found use of GIFs did make me chuckle Mr C! ^^^ Not quite, as it turned out. Although your new found use of GIFs did make me chuckle Mr C!Right, some slight alterations in the plan for last weekend meant Simon and I were doing harness and sensor checks on Saturday morning, entering the various parameters for (most of) the sensors dotted around the car. We identified a few strange things, like the ECU not powering down as you'd hope, but nothing that should've stopped the car from firing up on Sunday. Checks done, and I dashed off to the races for a mates 40th birthday. Very pleasant it was too, English countryside on a perfect summers day, gloriously Pimms O'Clock. Sundays agenda was then for Sam to come and play with the system, build some initial maps and see if we can get her to fire up. I have to confess, if ever there was a good use case for for the tag #mindblown, then this was it. Another incredibly clever guy, it was like having an 8hr masterclass in calibration theory. And quantum Physics (joke). Although I absolutely "got" the concepts, there's not a chance that much of it has stuck in the grey matter! It was during this time that it became very apparent just how good, and capable, the Syvecs unit is. I honestly hadn't quite appreciated this, not knowing quite what the background to Life Racing is (ex Pectel, sold to Cosworth, then went to develop engines - AER - then needed an electronics arm to control them, hence Life Racing). Then understanding where Syvecs have come from with their OEM partnership with Life Racing...all very interesting. To me, at least. Very reassuring to witness some of the intricate rules Sam has written that are now part of my calibration file, making absolutely sure that if there's anything untoward with the parameters that the ECU is seeing, it will cut the engine....way quicker than anyone could monitor from the cabin. However, it's not just a case of "if Oil-T = < xx ºC then kill engine", we're able to also build additional conditions (arguments) that specify a time element, that for example would cater for hot engine being shut down (ie fuel stop) and then needing to restart some short period later, perhaps catering for heat soak. I'm sure that makes no sense whatsoever, and it's only meant to be illustrative (it's also my poor interpretation and exhausted brain)...needless to say, it has it's roots very much in motorsport levels of robustness. Aerospace grade components used throughout with wider heat tolerances than off-the-shelf components, code written by the same guys who code the Life Racing range. Sitting adjacent to Sam in the office, in fact. The successful calibration between the throttle position pot, and the eGas throttle body, was completed; Sam being particularly happy with how accurate that has turned out to be. Again, he started showing me a myriad of oscilloscope trace windows (in the main Syvecs SCal interface) that were showing how much trim compensation and suchlike was needed in order to get the behaviour of the throttle body as he wanted it. Bear with me, I was struggling to even grasp the concepts of this; apparently very much in the PLD arena in terms of systems control. (#mindblown) But....did we manage to get the engine fired up? Nope. Unfortunately not, and I have to say, I was bitterly disappointed. But, a few days later, and a little perspective thrown against the situation, and it's not all bad. In fact, a long way from that. It was a very productive days work with building the calibration, discussing the project (it's the first time that Sam has seen the car) and importantly, sorting out a plan of action. We were hindered by an own-goal on my behalf. The bloody crank position sensor....again! If you cast your memory back 3 years (and about 30 pages) ago to when the engine was on the dyno for Build v1.0, we had issues with picking up a signal. In our rush to just get the damn thing fired up and running-in, we changed both the sensor for an inductive type, driven by the fact that the only spare MBE 9A9 ECU which was available, was configured for inductive sensors, not hall effect (in MBE systems, its not changeable, set at a HW level; Syvecs you can use either). We never did get to the bottom of why it didn't work, and suspected perhaps a faulty ECU. A few months ago, I decided to tidy things up with regards to the wiring; the inductive sensor we hurriedly used had about 75cm of cable attached to it, when we only needed 10cm. So I asked Simon to revert back to the HE sensor I'm using all over the car, for wheel speed and cam position; a Honeywell "1GT". I could then carry 1x spare sensor in my spares package, and be comfortable that I could change any one of 6 sensors if I needed to, and avoid being stranded. This then caused Sam and I some massive head scratching. VERY weird traces on the ECU diagnostics. Swapped a spare sensor in its place - same result. Chris very kindly then called us (what a legend), and guessed exactly what the problem was....the bloody 1GT sensor. In short, not suitable for 60-2 tooth flywheel resolutions. Old 964 Turbo dual mass flywheel? Possibly, less teeth, lower resolution. So, the problem was completely of my own making, me succumbing to OCD. At the moment, I'm waiting for a new sensor (inductive) to arrive.....I gave away the one that I *was* using to the guy who bought my old MBE ECU!! And it's no longer made by Bosch....With fortunate hindsight, Simon had run 4 feeds to the Deutch connector for the crank position; 3x electrical feeds and a screen, so no major surgery required to accommodate an inductive sensor, which obviously doesn't require a +5v feed. So, unfortunate but nevermind....it was a productive weekend, albeit hidden inside a lovely black anodised black box, rather than vapours being pumped out of exhaust tips. Last edited by Spenny_b; 06-06-2018 at 03:48 PM.. |

||

|

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

Spencer--

This a really instructive, informative post, that shows not only how far you have come with this project, but insight into the "reality" of sensor inputs. We like to think these are stable, constant inputs with predictable resistance ranges-- in fact, they are all over the place, influenced by EMFs, ground loops, weird transients, noise. In the analog world we just muddle through-- what do you really care if your oil pressure gauge oscillates below the level of the needle's dampening-- but in the ECU world it's GIGO-- garbage in, garbage out. The fact that you are plugged in to a community that fundamentally understands the forces at work, and how to compensate for them, is a HUGE differentiator for the success of your project. And for us. Carry on.

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

Kartoffelkopf

|

Evening folks, time for another update. A significant one this time!

The last few weeks have been spent being a) incredibly busy at work, and b) relentlessly pushing forward with diving activities, and getting Lucy qualified with her Open Water certs, ready to "hit the water diving" in Malta in 3 weeks time (and me continuing my Advanced OW, practicing a few things in readiness). That's now done, Lucy's now OW certified, and we're good to go. Time to crack on with the car project. Simon made another trip across last weekend to make some changes to the harness, and to make a jumper harness for the new crank position sensor. The previous HE sensor used a Deutsch 4w connector, with +V, -V and Gnd, the new inductive (VR) sensor uses Sig +, Sig - and a Screen; thankfully Simon had the foresight to run a screen through the harness, so a simple adapter from Deutsch to the successor to the 3w junior mini-timer connector that Bosch are now using. Some health-checking and it was job-done for the day. The new Bosch crank sensor is an even easier fit into the original sensor mounting bracket that mounts onto the back of the crankcase half, poking through the bellhousing aperture. No adapters needed to cater for a longer C-C on the mounting bolt, nor any spacing required to cater for the sensor being longer; it just drops straight in.  Firing up the Syvecs S-Cal s/w to hack my way around and find a way to monitor the crank pulse waveform, and all looks good (although the shot below was taken before I zoomed into the top trace, which revealed the 60 pulses, then the indexing gap)  Every evening for the last week I've then been playing around and getting the car into a state where we can drive it this weekend, as opposed to just getting it to a point where we can fire the engine up. Lots of odd-and-sods jobs to be done, not least of which to sort out a few leaks on my water cooling system. Nothing major, just teething problems. Sam arrived again yesterday morning for session #2; the obvious aim being to ultimately get the car out onto the public highway for a shakedown and to ensure all parameters are reading correctly before leaving me to it, to run in the engine on the road over the next month or so. So, first check was to make sure we had a good crank pulse - and we did, no problems at all. Second cranking on the starter, I thought was going to be to just check phasing of cam position v crank. What I wasn't expecting (or I would've rigged up the GoPro in advance) was that engine would burst into life! What I then discovered moments after shutdown, was that the top set of coils weren't even connected! We (Simon and I) deliberately disconnected them a few weeks ago, in case the ignition was inadvertently switched on without the correct setting for the coils being set up - didn't want to fry them, of course. I'd got as far as reconnecting the easy-to-get-to lower plugs, but not the tops - I wasn't expecting a start sequence! I think you'll agree, she sound pretty damn sweet for the very first firing!!! (especially on only the lower 6 plugs) This is the second fire-up. The safety strategy that Sam has programmed in prevents the engine firing until a decently high oil pressure has been achieved, hence the long "pull" on the starter motor. So, all's going well, but we had a few hiccups shortly after. The Lambda sensor simply wasn't reading for some reason. After some head scratching, we realised that the Syvecs S6+ motherboard is "wired" for the Bosch 4.2 type sensor, not the 4.9 sensor which I'm using. However, a very easy thing to fix; a dozen or so hex bolts later and we're doing open-heart surgery on the main board, un-soldering 2x bridging pads and re-soldering them to different positions. If you can imagine 3x pads in a line, A, B and C, where B is common. B bridged to C = Bosch 4.2, or B bridged to A = Bosch 4.9. This needed to be done on 2 sets of pads to effect the change (and is entirely above-board, described in their manual, so not a hack by any stretch, it's just needed in order to support a wide range of sensors, incl NTK). All OK after that? Hmm, not really, we could now see readings, but the sensor simply wasn't heating up as it should. Although it was a new part for Engine Build #1, it's entirely likely that it became contaminated with what happened last time, blow-by gases, or perhaps a temperature shock, etc. So, an hours round-trip drive to buy the one remaining unit that was in stock in the local area, and it's all great again....perfect readings. £100 lighter but a big relief. (back-to-back re-testing of the old sensor later confirmed it was shot). Apparently it is known that the Bosch units are a little fragile, certainly not as robust as the NTK units AER/Life Racing use for their motorsport applications....but they are 1/4 > 1/3rd the price. And available on a Saturday afternoon. Many hours then spent with Sam tweaking maps, whilst I continue my work to get the car drivable. Items deliberately left unfitted, like the intercooler, inlet snorkel, breather catch tank, etc, all needed to be fitted now that we had inspected for leaks. I tell you, the workout I got for that whole days activities was immense. As some of you know, we're going through week 4 of a heatwave here in the UK (nothing compared to Arizona or some parts of SA, for sure, but for us Brits, it's very nice and hot). This coupled with a stinking hot car that's heating up the garage nicely, and I'm sweating like a good'un. Wheels back on, off the ramps and time to drive it. Gulp. First impressions? Wow....not at all bad for the first stab at making sure it has road manners. Some initial over sensitivity was easily dealt with by Sam, perched on the back set (no front passenger seat in the car yet!) with laptop on, er, lap. This thing wants to make boost REALLY quickly; My insistence on Sam applying "Nanny State" limits to revs, boost and throttle opening meant that he had to knock the eGas opening down to just 20% (from 40% initially) so that it's not quite so quick to crash into the 0.7bar boost max that he originally set. A 10-15mile run out, no dramas at all. No stalling at junctions, pulling away from standstill is beautifully smooth and she idles superbly. Oil temps all well under control. There are still some tasks to be completed though. Firstly, the tacho drive either needs to be enabled from the ECU, or some wiring needs to be looked at. It was previously wired into the harness for the MBE ECU, so I'm hoping nothings changed in that regard, and it's just s/w enablement. The oil level gauge on the dashboard is all over the place, reading intermittently. Needs pulling and testing. The oil pressure gauge is over-reading compared to the ECU. At 3,000 rpm the Syvecs is showing 3.9bar, but the dash is declaring >5 bar (i.e. off the scale). There's a fair amount of electrical noise when monitoring #6 cylinder knock. It's not knock itself, more of an unclean signal versus the other cylinders (not seen it on the S-Cal sw, so can't comment any further than this) There's an annoying buzz from the front fuel pump; I think there's metal-to-metal contact somewhere, perhaps an inlet/outlet fitting. Underbody panels need refitting, as does the rear bumper, then time to pile on the miles with frequent inspections. So, a fantastic weekend, major milestone reached. But...I'm trying not to get too excited. Been here once before, where everything sounded great but suspicious symptoms proved otherwise. I'm sure with all the rules and safety settings that Sam has plumbed in, nothing untoward can happen. In his words, everything is set to "paranoid" levels of safety, where even the briefest loss in oil pressure will kill the engine. Last edited by Spenny_b; 07-08-2018 at 03:44 PM.. |

||

|

|

|

|

Registered

|

I am very satisfied for you Spencer!

|

||

|

|

|

|

Registered

Join Date: Mar 2005

Location: Phoenix, AZ

Posts: 2,862

|

Great news, another major milestone behind you.

__________________

Chris Carroll TurboKraft, Inc. Tel. 480.969.0911 email: info@turbokraft.com http://www.facebook.com/TurboKraft - http://www.instagram.com/TurboKraft |

||

|

|

|

|

Kartoffelkopf

|

|||

|

|

|

|

Kartoffelkopf

|

|||

|

|

|

|

Kartoffelkopf

|

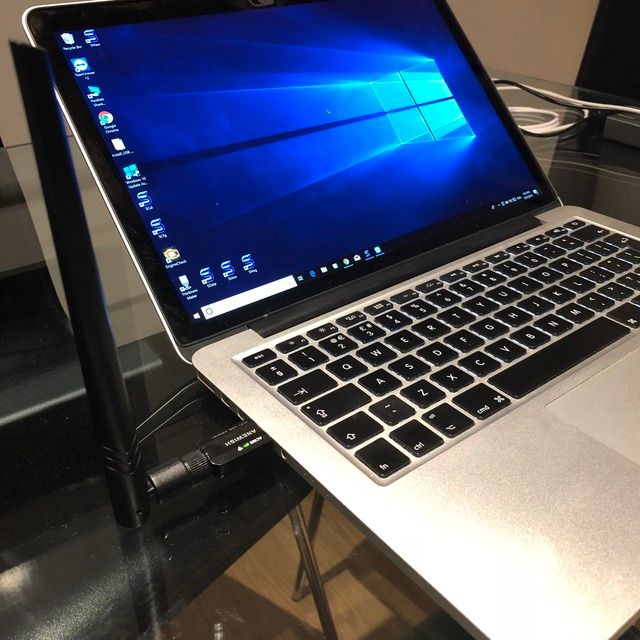

Okay, mini-update....

We were originally scheduled to be up with Northampton Motorsport on the 11th August for the dyno runs; unfortunately, due to work commitments, Sam has had to postpone....now looking to be early September. Not the end of the world, a) it's very close to being road legal and usable, and b) 11 Aug all of a sudden feels quite close, especially with a diving holiday in between. We all know how tight things get if there are any snags that need addressing, so I'm not too upset about it. As I type this, the car was due to be at my pals for its annual MoT test, however, something that we didn't do before Sam left on Saturday, was to leave the car with a calibration that'll get it through the emissions test. Should be easy enough to correct, some remote dial-in work onto my laptop and then supercede the calibration file?....well in theory yes, except that despite me having a valid connection from my laptop last week (Macbook Pro, running Win 10 under Parallels), it just will NOT connect again now. Beyond annoying. So, time to try 3 other Win10 devices I have, all running native Windows rather than virtualised - same result with them, constant "Offline" being displayed. The Syvecs unit doesn't use the full TCP/IP protocol stack, thus doesn't use/issue IP addresses (therefore DHCP is no use). Difficult to diagnose, no way to ping it, only to monitor I/O traffic via the Windows networking setup and diagnostics screens. Indeed, there was handshaking going on, but once done, no continuous comms. At one point I thought I had a faulty Thunderbolt>RJ45 adapter (and still not convinced it's not broken), so another quick dash out to the local PC shop to buy a USB>RJ45 adapter, but to no avail. However....this lunchtime, I decided to have a go at configuring the TPLink mini router I bought specifically for this job. I hadn't used it thus far, working on the KISS principle, surely a plugged in network cable has got to be simpler than trying to configure a wi-fi access point? Well, after switching some of the TPLink settings (for it to actually behave as an Access Point) it all connected beautifully!! Both my Mac and my Acer tablet. Excellent. Team Viewer also installed, so as soon as Sam has a spare window, he can remote in and do-the-necessary. "Look Mum, no wires!"   Chaos in the cabin, yet to be mounted but it's all live....  In the meantime, the rear bumper has now gone back on, but not fully bolted in place under the rear quarter panels. The lights and reflector are back in, and bloody hell, she looks gorgeous again...Ok, a little dirty, but I've got my 964 back!!  Oh, and I finally got around to adjusting the engine cover latch! For ages, it's been a case of stretching between the lid release puller and simultaneously using your right hand to lift up the wing. I won't pretend that adjusting it was the work of 5 minutes - it very much wasn't - but it now releases with my dignity intact. Last edited by Spenny_b; 07-11-2018 at 09:25 AM.. |

||

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

Its alive! ALIVE!

Classically, there are a bunch of small items. Of course you have the right approach, make a list and check everything off. Nitrox?

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

Kartoffelkopf

|

|||

|

|

|

|

Registered

|

Being blown away by the level of detail and commitment in your work, I have silently been following, hoping to see you bring this back where it belongs. I am very happy to catch up on the latest achievements, it appears you are closer than ever to where you deserve to be.

A huge congrats from Denmark. Cheers

__________________

Jesper Carrera 3.0 1975 930 1978 OEM Matte Schwartz, ANDIAL IC, BL WUR, SC cams. LMA-3 w. XD-16 and CP transducer www.stauningwhisky.dk |

||

|

|

|

|

Kartoffelkopf

|

Quote:

Cheers Jesper, appreciate the generous comments. Yeah, hoping that the end is in sight, there are so many other projects I want to switch my attention to (not car projects! I'll never do this again!!) Cheers Jesper, appreciate the generous comments. Yeah, hoping that the end is in sight, there are so many other projects I want to switch my attention to (not car projects! I'll never do this again!!)

|

||

|

|

|

|

Kartoffelkopf

|

Okay, time for an update.

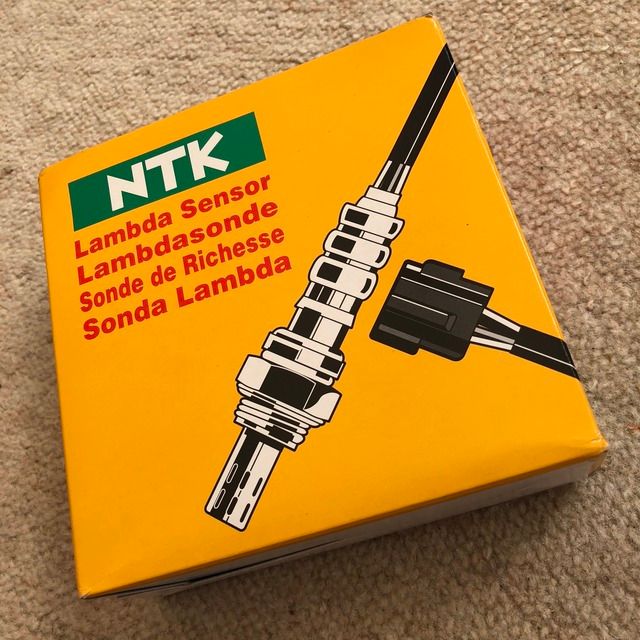

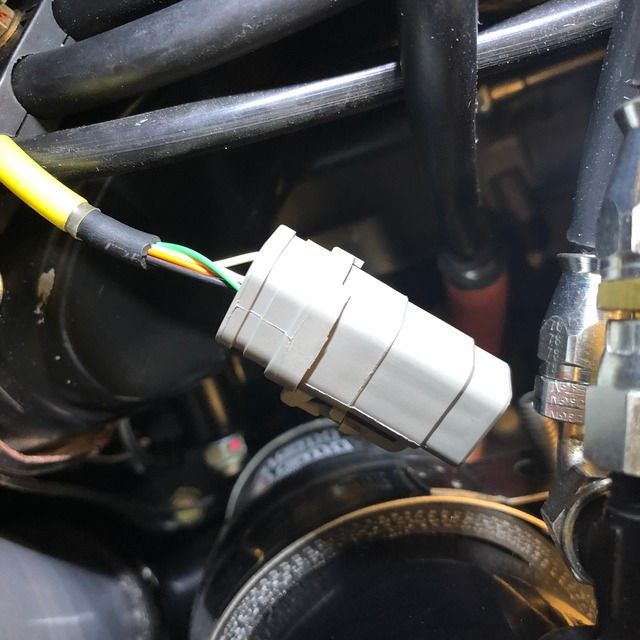

The bumper's back off, along with inner arch liners.   Remember the new Bosch Lambda sensor I had to buy a few weeks ago? Well, we had another remote session for Sam to adjust the calibration in order to pass the emissions test for the UK MoT, but all was not well again. No heating control despite a clear heat-up ramping profile. Cue the face/palm despair. And swearing. I should explain at this point that the Syvecs S6+ unit has a daughterboard, essentially the bot that makes an S6 into an S6+. It adds inputs/outputs, but also has the Bosch CJ125 controller chip mounted on it; the chip that controls the LSU4.2 and LSU4.9 sensors. The mainboard is made by Life Racing, as well as the code for this being written by them, but the daughterboard is made for Syvecs by a 3rd party, and I presume that the associated code is written by either the 3rd party or by Syvecs themselves. Why is this relevant? Well, it turns out there was some issue that was discovered with that CJ125 chip concerning the code. The only announcement that I'm aware of was the final post in a thread on the Syvecs forum! Hmm. So, we've potentially f***ed a brand new Bosch sensor because of a code issue. Terrific. A code reflash to the daughterboard later (easy enough), and time to give it another go. Any better? No. Different behaviour but ultimately still not working well enough. Looking at the control parameters of what the new code is now doing, it's not subtly different, it's radically altered (apparently). The Lambda now looks to be heating up fine, but then "dropping off a cliff" once up to temperature. A complete head-scratcher, which nobody seems to know what to do about. Emails off to Syvecs support, and no reply back. Not that impressed, I have to say. I've read and learnt more about Lambda sensors than I ever wanted to know, and it seems that Syvecs (Life Racing) very much seems to be designed around the NTK sensors rather than Bosch (a conclusion I've come to after reading about more frequent updates to linearisation curves, and far more chat traffic on the forum from the design guys at Syvecs). The NTK sensor is controlled directly by the mainboard, not the daughterboard, so is using Life Racing code. There's essentially 3 different types of NTK probes; There's some mention of an L1H1, but this was superceded by the L2H2 some years ago, with a part number of LZA-09-E1. It's an off-the-shelf unit as fitted to Honda Civics (amongst others). Readily available and is anywhere from £115 - £180. Then there's the LZA-03-E1, known as the "motorsport" sensor; higher quality, but twice the price, and not at all easily available, with supply contracts in place between (I think) Life Racing and NTK. Above that, there's a Lab grade NTK sensor, used for calibration and workshop monitoring systems, i.e., the kit used on dyno's. These are reassuringly, breathtakingly expensive, and not what's used on the car itself. Another point of note is that the Bosch sensor has calibration resistors built into the plug, and so you can't shorten and re-terminate an LSU4.9 (or 4.2, I think). The NTK doesn't have these resistors built in, and can be re-terminated with a non-NTK plug if desired; commonly used is the MIL spec plug, more heatproof than the stock plastic unit, or Deutsch for something cheaper and smaller. Calibration – if required – is then done in the linearization curves, which are in the SCal software. Long story a little shorter, I don’t want to continue cocking-about trying to get a Bosch sensor working, and then worrying that it may just decide to give-up one day – it’s a pain to change, the bumper has to come back off to access it. So, I’ve gone with an off-the-shelf NTK L2H2 unit.   Sam’s very happy with these sensors, having used them many times before in motorsport applications (non-works, “privateer”) and in his own cars. Northampton Motorsport (who are going to be dyno’ing the car in September) also speak highly of the NTK unit, having had poor experiences with the Bosch sensor previously. They also said anecdotally that the linearisation curves, when compared to their very expensive workshop unit, are spot-on identical; all pretty reassuring. I’m also keeping the stock termination; if I ever do need to replace one “in the field” (and they ought to be considered a service item really), I certainly don’t want to be thwarted by then having to re-terminate with a MIL/Deutsch connector. So, decision made – the next job was to rework the wiring harness, which has a Bosch connector. Not the easiest thing to get to, however, removal of the intake snorkel and intercooler and I can *just about* get enough access. Chop off the Bosch plug and refit a 6w Deutsch connector.    (heatshrink boot deliberately not fitted until we test it) Simon has made me a 40cm interfacing harness, Deutsch at one end, NTK plug the other all wrapped in Raychem DR25.  Lambda now screwed into the exhaust, and wired up – we’re ready for another fire-up attempt tomorrow evening. If OK, then I can book the MoT for when I get back from vacation.

|

||

|

|

|

|

Kartoffelkopf

|

In parallel, I’ve also been trying to get the hard-wired Cat6 cable from the ECU to talk to the laptop without going through the wifi router….not that I want to use it this way, but it *should* work like this…and it isn’t…and it’s pissing me right off. Tried everything I can think of, checked the Tx/Rx connections into the ECU, which are all fine, I’ve even made up another Cat6 cable and substituted it into the harness. Slightly different result; SCal now intermittently (when it does detect the ECU) declares that the calibration files are locked, implying that there’s a concurrent connection into the ECU from another device that’s also running SCal. And there most certainly isn’t.

Life’s too short, and ultimately I only want to use Wifi to connect anyway. But with only a single wifi aerial in the Mac, I needed to get an additional wifi adapter, or else continue using a 25m Cat5e cable that runs from the house into the garage (far from ideal). £10 for one of these via Amazon…..  ….and at last, I’m able to setup one aerial for connecting to the house router for Team Viewer remote access, and the other connection to the Syvecs wifi router for SCal access, all fine running on Win10 virtualised under the Parallels hypervisor and OSX High Sierra (as tested by using Team Viewer in the OSX environment, to then remotely connect to the Win10 environment and in to SCal). More updates over the next day or so. Hopefully. Last edited by Spenny_b; 07-26-2018 at 06:00 PM.. |

||

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

Freddie Uncle Charlie Kate. I should have pressured you into Motec when I had the chance.

Your perseverance has taken on entirely new dimensions. The stiff upper is now forged titanium. You are a better man than I: anytime I run Parallels to emulate windows, my uncrashable Mac. . . crashes. I think it can SMELL MS code. I close with this:

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

|

|

| Tags |

| 964 c4/c2/turbo , efi conversion , life racing , syvecs , turbokraft |