|

|

|

|

|

|

|

|

|

|

|

Registered

Join Date: Mar 2005

Location: Phoenix, AZ

Posts: 2,862

|

MAP and Baro sensors

Spenny -- thought you decided to run the lab grade pressure transducers?

__________________

Chris Carroll TurboKraft, Inc. Tel. 480.969.0911 email: info@turbokraft.com http://www.facebook.com/TurboKraft - http://www.instagram.com/TurboKraft |

||

|

|

|

|

Kartoffelkopf

|

Quote:

A 3am finish again this morning (work) then a 7am start to travel up to London means I'm probably not going to get out in the garage tonight, need to get some zzz's...but tomorrow I'll snap a pic of the underside of the sensor station to show better how stuff's connected. Cheers S

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

Quote:

By fitting the T directly to the BCV with a fem>fem adapter, it does save a few fittings but still, it's not particularly elegant...time for another trip to Think Auto to see what else we could do...like the T with one of the branches as a 1/8th NPT I'll spend some time drawing up the connections to the WG's, Boost valve, turbo, etc, but yes, pretty much as you have it there; lot's of tee'ing of lines so that both WG's can operate in parallel from the single valve. Quote:

Quote:

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

|||

|

|

|

|

Kartoffelkopf

|

Wastegate Plumbing.....

As you may remember from the updates a week or two ago, some of the plumbing possibilities were causing me to spend a lot of time trying stuff out, swap a lot of fittings at Think Auto, and generally drink lots of tea.

But...finally nailed it and have to say, glad I spent the time doing this rather than rush it. Good suggestion John re the running NPTF/-4AN "T" into the boost control solenoid. All lines are now in place - albeit only hand tight for the time being - and covered in clear heatshrink to avoid any abrasion. Those lines that need it have also got lengths of thermo sleeve to protect against local exhaust heat. Rubber grommets also fitted whilst assembling the lines, to seal up the holes in the side tinware. I also managed to re-use the original spark plug lead clips, to keep the lines pinned to the fan shroud....needed drilling out to 9mm, but not planning on using them with HT leads again! LH Wastegate --->  Boost Control Solenoid - yet to be bolted down. I'm planning on making a raised platform to mount it on, then welding this onto the coil/intercooler bracket, so that it clears the nuts and studs...of course, this will be central on the parent bracket. The running "T" is also going to get the de-blueing treatment --->  The "T" fittings to facilitate running 2 x WG's from the single solenoid --->  RHS of shroud --->  RH Wastegate --->  Boost signal from charge pipe --->  Next job, to finish the sensor bracket and the hoses that run to those sensors. Been spending time investigating some of the items needed for the wiring loom, like where to take wheel speed sensor signals from for the traction control. I now have some very nice CAD drawings of the loom. For once, I'm glad it's not me making it!

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

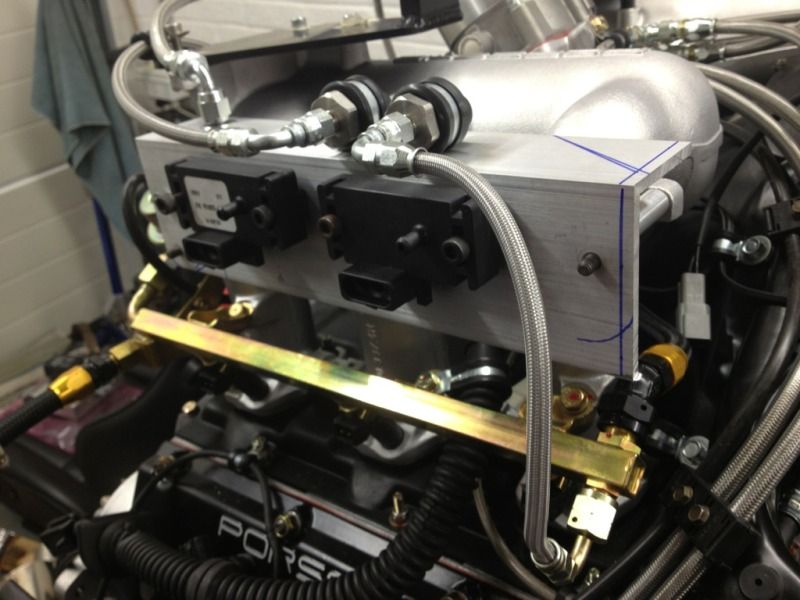

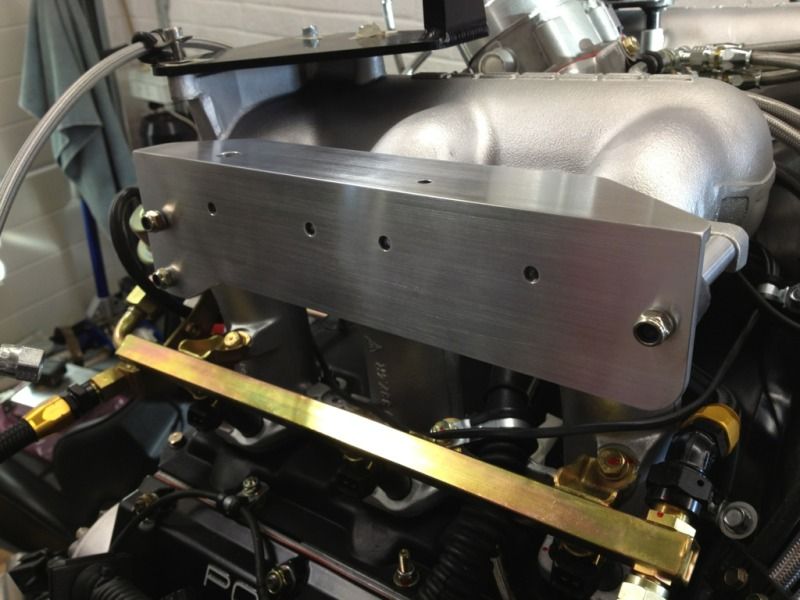

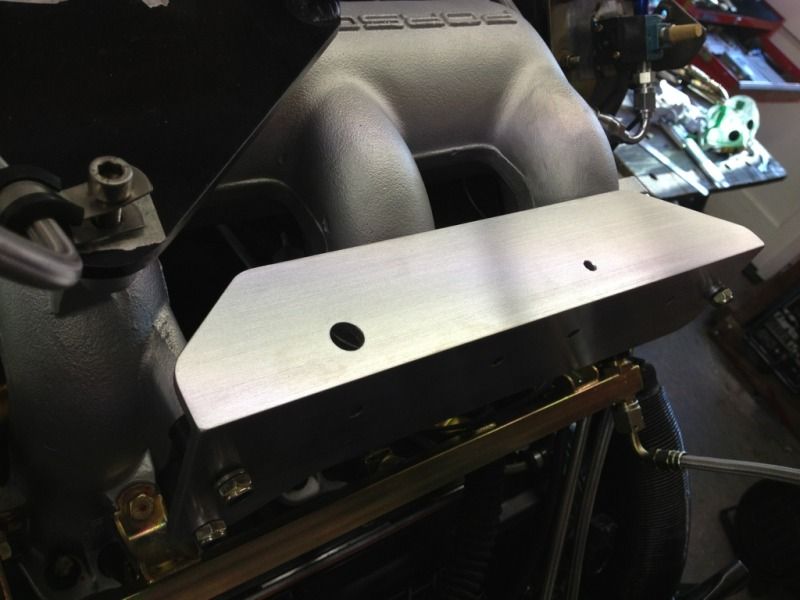

Sensor bracket

Very productive weekend. One of the items now completed is the sensor bracket, which houses:

This is the roughed-out bracket, but far too big (...heavy  ) ---> ) ---> After some slimming down --->  Note the replication of angles and radiused corners, per the TurboKraft I/C bracket  (Jony Ive isn't the only aesthete...although that and a British accent is about all I probably have in common (Jony Ive isn't the only aesthete...although that and a British accent is about all I probably have in common  ) ---> ) --->    I've just got to be careful not to put any scratches into it before it goes to be anodised in the same black finish as the I/C and associated brackets.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

Other weekend progress was to get the exhaust headers welded; previously the wastegate feeds were just tacked, but now all neatly welded by Febweld. Great job as ever. Gave them a quick going over with the wire brush to tidy them up a little:

Also welded a platform onto the old coil bracket that now houses the boost control solenoid. Now also ready for re-plating:   The fuel return hose from the fuel pressure regulator back to the rail-mounted fitting. Needed to buy a couple of pretty expensive metric fittings for these, as the angles were just too tight without putting in a loop:  Hoses to the BOV and boost pressure sender (used for the OBC display) also now finished, along with oil and fuel pressure sender -3 hoses.  Tonights job is to watch the Steelers at Baltimore and finish the rear valance tinware...a job that's been dragging on for weeks, mainly because it bores me to tears but the sooner I get it done, the sooner I can now get everything off to the powder coating and plating. shops.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Registered

|

Subscribed.

|

||

|

|

|

|

Moderator

Join Date: Dec 2001

Posts: 9,569

|

Can't you catch the FPR output with a 120? Looking bloody gorgeous as I have said for years

__________________

'66 911 #304065 Irischgruen ‘96 993 Carrera 2 Polarsilber '81 R65 Ex-'71 911 PCA C-Stock Club Racer #806 (Sold 5/15/13) Ex-'88 Carrera (Sold 3/29/02) Ex-'91 Carrera 2 Cabriolet (Sold 8/20/04) Ex-'89 944 Turbo S (Sold 8/21/20) |

||

|

|

|

|

Registered

|

I don't think there is enough room for the fittings. I've tried a number of approaches but settled on using a barb 90 degree elbow with 2 short sections of 5/16 multi-fuel hose and EFI hose clamps. Crude in comparison to above.

__________________

Steve Sapere aude 1983 3.4L 911SC turbo. Sold |

||

|

|

|

|

Kartoffelkopf

|

Quote:

No, doesn't *quite* work unfortunately....I tried swapping the 120deg elbow onto the FPR, but by the time a straight fitting goes onto the rail, the angle is too tight for a piece of hose (and too short, v little room to fit the gold clamp on). At least this way I can loosen the fittings if needed, to swivel them around to clear "stuff".

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

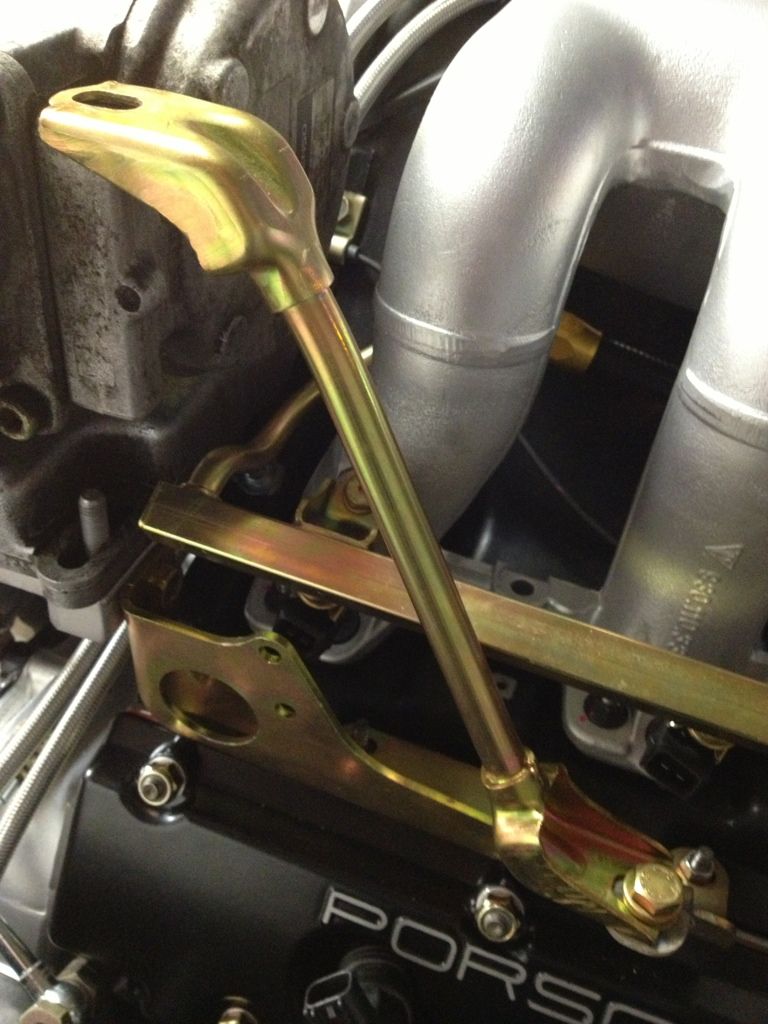

A couple more updates this evening. One job that's been puzzling me is thinking about the best way of making a new A/C pump support bracket. The whole setup is quite a lot different from the earlier Carrera's that have the same intake as I'm using; different pump on the 964 Turbos, with a diagonal strut that fixes to a plate that sits under a second plate, holding the P/S pump.

However, the diagonal strut now hits the injection rail; of course, there was no injection rail on the CIS system. So, working on the premise that it's always easier to get the parts in-situ before trying to over think anything, I finally got around to putting the pump in position, lo-and-behold, the answer was immediately obvious. This is how the bracket originally located the diagonal strut --->  Lightbulb moment....chop the 90deg return with welded nut, and reverse it --->   Need to clean that filthy A/C pump. At the very least I can separate the aluminium cradle and get that vapour blasted.....has anyone stripped down a pump before?! I've also got the turbo oil drain tank tacked-up for dummy fitting...pics of that later.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject Last edited by Spenny_b; 12-04-2012 at 12:36 PM.. |

||

|

|

|

|

Registered

Join Date: Jun 2006

Location: jacksonville, florida

Posts: 177

|

Everything is looking great with your project- speaking of your turbo oil drain pot, was thinking about your turbo cooling comments from a page or so back- have you considered oil cooling the turbo instead of water? Have done this many times and it works great, functional and keeps things compact, no need to run coolant lines, pumps tanks to cool the water jackets. Just have to have the outlet at a slightly HIGHER angle than the inlet. You can use your primary turbo lubrication feed and "T" off it, using one for lube and one for cooling. More than enough volume of oil left over to do the job, esp running a Garrett with restrictor. I personally like the simplicity and as you know, space is always at a premium.

In the pics, the feed side is hard to see but you get the idea.

|

||

|

|

|

|

Kartoffelkopf

|

Hi Seth,

Many thanks for taking the time to post some pics...interesting...despite reading about folk using oil to cool the turbo, I've never actually seen photos. I *thought* I read on another thread that oil was perhaps not the best medium to use, due to its weight and therefore ability to transfer the absorbed heat.....IIRC...just trying to recollect the comments in the other thread. I actually want to cool the wastegates as well, so need water for that...of course, there'll be plenty of folk screaming that this is all way over the top and unnecessary....this falls very much in the "because I can" and "sod it, lets experiment" category! (along with the eGas/eThrottle and traction control of course)  Talking of which, despite me marking up the oil drain tank as accurately as I could, to get it tacked, it was fractionally out on the turbo exit tube when I tried it last night (how bloody predictable), so it's Plan B time....not at home tonight, so no playing, but will post pics as soon as I can...

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

A couple of updates....

So, at long last, the tinware modifications at the rear of the engine are now finished. This was one of those fiddly jobs, needing lots of patience and plenty of cardboard to make templates with. Really glad this one is done!

Very happy with the outcome - I messed up the first attempt, wasn't happy with how I put the stepped folds in, where it fixes to the chain covers. So, attempt #2 and the outcome was FAR better, and also better clearances around the turbo compressor outlet and the oil tank breather tube:   Rear tinware now away for final welding, so is the oil catch tank for the turbo...hopefully these will be ready for Friday, then it's off to take a big batch of stuff over to the platers and powder-coating shop. Doubtful whether I'll get everything back for Christmas, but I have another project I'm working on that'll keep me busy over the Xmas/NY break

|

||

|

|

|

|

Kartoffelkopf

|

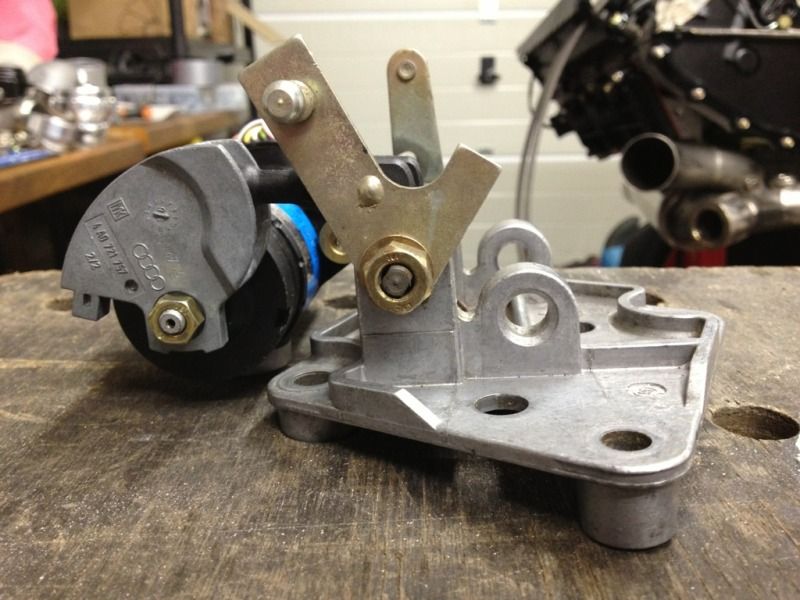

In parallel with doing the tinware and catch-tank, I've also been investigating a few more options for the eThrottle/eGas.

The plan *was* to use a GM/Vauxhall fly-by-wire throttle pedal and either use the pedal as-is (save for a few fabricated mods to the metal part of the pedal), therefore replacing the stock pedal. Hmm, wasn't too keen on doing this, as I want it to look stock inside....but would've been fairly easy, with just a sub-loom running to the front footwell from the ECU. Another option was to butcher the same pedal, utilising just the electronic part, then fabricating a lever which could be operated by the original pedal and cable setup. The downside for this was that it'd look a little Heath Robinson, with a pretty long lever to enable the full pedal travel. Accommodating the unit wouldn't be the easiest either, especially with that lever. Then, on a fly-by visit to SBD the other day, Steve mentioned that he'd sourced an eThrottle position sensor from an Audi A8, fitted to the model before the full electronic pedal was available. A Bosch unit and in summary it was brilliant; small, light and importantly, cable operated with a heavy return spring load, so no complicated cams or levers needed. Not many on eBay, but got one for a fairly reasonable price (they're £330+VAT new), which arrived today. A classic case of having to have the part in your hand, before you can sensibly plan how to use it (although I had a pretty good idea). I then measured the travel distance that the cable moves (23mm) and the distance the throttle pedal moves the cable (56mm). Lo-and-behold, this could be the easiest modification in this project yet! Using the stock throttle linkage, bolted to the stock mountings on the engine, it'll mount behind the linkage on a new fabricated cradle. The pin on the levers that usually actuate the return spring, are perfect to use for fixing the eye of the eThrottle. I can then use the stock ball/cup fixing for fixing the throttle cable. A slight re-indexing of the cable and pulley assembly an hey presto! So, in theory, I could use the linkage as-is. What I'll probably end up doing is making a new set of levers, removing any excess material, and then making a stronger "pin" for mounting the cable/eye, then get it all plated. No need for the old return spring, the built-in one is slightly stronger than stock. So....time to find more cereal packets and make a template for the eThrottle cradle!

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

And finally....

...I've decided to re-work the position of the dump valve/BOV...without actually offering it up inside the engine, it was 50/50 as to whether the unit would foul on the rear bulkhead. If it didn't, then it'd be REALLY close.

After deliberating whether I wanted to hack-up a really nicely welded charge pipe (not really), I decided that the alternative would mean having to re-work the pipe after it had been black anodized, it'd certainly delay getting everything back in the car (probably a 2wk leadtime on the re-plating, once modified), plus almost certainly impact the booking of the rolling road (6-8wk leadtime) and not something you want to find out on the big day of re-installing the engine. So, time to bite the bullet. The pipe has now been cut, the BOV flange removed and a new middle section ready to go in. I have a choice of where to re-position....thoughts welcome. From a aesthetics perspective I'm leaning towards mounting it on the right hand side on the apex of the bend, but not sure if I mess up the velocity of the intake?  Another option is to keep the position the same but rotate so it hangs upside down. There's just about enough clearance but not keen on how it looks.  I'm also going to weld on 2x lugs onto the "cup" that sits on the throttle body, just as a precaution to prevent anything popping the charge pipe off. Using only two lugs will allow the eThrottle to be aligned and bolted to the intake manifold, then a couple of lugs mounted opposite each other will hold on the charge pipe.

|

||

|

|

|

|

Kartoffelkopf

|

Nothing major happening at the moment, just some fabrication work to finish the oil drain tank for the turbo, and to re-make the cold side charge pipe from the IC to the eThrottle.

Chopped out the centre section of the previous charge pipe, removed the BOV flange and tidied it up again, then made a new piece to sit in the middle of the 2 x 90deg bends. This is all tacked in place again, along with 2 x lugs that will hold the pipe firmly in place to the throttle body:    Will drop these over to be welded tomorrow during the lunchbreak. Far happier with v2.0, the pipe alignment is straighter, smaller gaps in between each section, meaning that I shouldn't get the prob I had previously where it all pulled up when fully welded, throwing the alignment to the IC off by about 2-3mm. Have had a re-think on the throttle linkage shown previously. Rather than sitting a plate on top of the original assembly, I'm making a whole new plate with the mounting lugs underneath...so, very much in the spirit of the original, same mounting position and shape, but the spindle will be a lot shorter, held inbetween 2x flanged oilite bearings. The steel levers on the shaft will be very much the same, as dimensionally it worked out nicely, but this will be a whole lot neater than using a two piece solution. I also found that the mounting heights weren't working out too well with the thickness of the ally plate, meaning the angle of pulling on the eGas position sensor was far from ideal. I'll crack on with that over the Xmas break, pics to follow...along with my new remodelled and twice-the-size garage, which will commence in early Jan, woo-hoo!

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Registered

|

Hi Spenny

Amazing build! I need to rework the throttle cable setup on my engine. Could you explain a little more on the eThrottle? What parts (partnumbers?) are you using, for throttle pedal and servo. Are they stand alone and work independent of an ECU?

__________________

Magnus 911 Silver Targa -77, 3.2 -84 with custom ITBs and EFI. 911T Coupe -69, 3.6, G50, "RSR", track day. 924 -79 Rat Rod EFI/Turbo 375whp@1.85bar. 931 -79 under total restoration. |

||

|

|

|

|

|

Kartoffelkopf

|

Quote:

Haha, the eThrottle...I'm not the expert on this, I'm leaving it to my mate who is the mapping genius, however, they certainly don't work independently of the ECU I'm afraid. The throttle body is a 997 unit from a Carrera - I just picked the p/n from the 997 PET and spoke to a UK based Porsche breakers yard; they happened to have one on the shelf in almost new condition. Having had a look on eBay for the position sensor, I also saw a LOT of these Bosch units for sale....not necessarily Porsche items, but so long as it has the 82.6mm OD housing, then that should do the job. The original plan was to use a Vauxhall/Opel/GM eThrottle pedal assembly. I was going to mount this in the engine bay (with some fabrication to re-work the actual foot pedal part), and actuate this lever with the original cable pull from the cabin. This wouldn't have been the easiest nor neatest way, as the angular movement of the potentiometer is very small, meaning that a very long lever would be needed in order to allow the cabin throttle pedal to pull the cable the whole 53 or 56mm (I forget which). Another option would be to use a BMW floor hinged eThrottle pedal, replacing the original 965 one in the footwell....but I wanted to keep it looking stock. The option we've gone with for both Steves OMS single seater hillclimb/sprint car and mine, is another Bosch unit, for the Audi A8 or A6. This is the unit shown previously, and was used on the cars prior to a full eThrottle pedal, ie., they still used a cable to pull and rotate this unit. It has more angular rotation, so is easier to accommodate and build levers for. A point to note, however, is that all items had to be sent to MBE so that they could build calibration maps for them....I assume any other ECU manufacturer will have to do the same. I did suggest to Steve, how about mounting something like a Penny & Giles high-end throttle pot onto the OE throttle linkage, but there would be issues with doing this, apparently we'd need 2 units to do a comparative reading from, then the MBE code would need re-writing (expensive and time consuming)...there are parts of the code that MBE keep locked from users for safety reasons, and I believe this is one example (you can imagine the consequences of somebody messing this bit up!!) We're going to be using FBW throttle to control traction, launch and general driveability, one example being the classic scenario where you're in the wrong gear, go to accelerate and the engine bogs down (although I can't imagine that being too much of an issue in this instance!), the ECU can then control and only allow a %'age throttle opening to ensure the best result....not a great explanation but you perhaps get the idea. I think the TC and LC functions will be the most interesting, with variable settings for each in the cabin. LC could be useful, not to get blistering hot F1 style getaways, but more of a way of ensuring you don't completely smoke the tyres in 1st/2nd (3rd/4th...), so almost a way of limiting boost per gear (but not.....yet...) Cheers Spencer

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject Last edited by Spenny_b; 12-23-2012 at 08:42 AM.. |

||

|

|

|

|

Registered

|

Aha, I understand!

Do you have the part number of this Audi part?

__________________

Magnus 911 Silver Targa -77, 3.2 -84 with custom ITBs and EFI. 911T Coupe -69, 3.6, G50, "RSR", track day. 924 -79 Rat Rod EFI/Turbo 375whp@1.85bar. 931 -79 under total restoration. |

||

|

|

|

|

|

|

| Tags |

| 964 c4/c2/turbo , efi conversion , life racing , syvecs , turbokraft |