|

|

|

|

|

|

|

|

|

|

|

Kartoffelkopf

|

Quote:

Yes, I did get email mate, I'll shoot you one back, probably tomorrow when I'm on the train into Town....want to get this build down on paper before I start forgetting stuff, lol. (No, no Spenny_B garage, haha....much as I would love to do this full-time, I can't help feeling that the fun goes right outta the window when you're up against deadlines and other peoples attitudes to a proper job and the "good enough" syndrome) Watch this space....

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

A little more head work

One little snag-ette I found, was the variation in the cylinder fire-ring channel depths, which manifested itself by the heads not sitting down onto the cylinder; being held off by the thickness of the fire ring.

Now, folk may be asking why I'm even running with fire-rings. If you remember back to the sorry episode with the fit-for-(s)crap Capricorn cylinders a certain somebody tried shafting me with, I needed to have my heads machined to be able to work with the fire-ringed Capricorns. Then they were returned, but of course I'm left with heads that are ringed, and so the Nickies then also needed to be machined to work with my heads. Clear? Great.... Anyway back on track...Not sure why the variation in channel depth, but the quickest way to fix (bearing in mind I’m in the UK) was to alter the fire rings. I ended up making a mandrel so that I could mount them in the lathe. Too thin to grip in/on the chucks internal/external jaws, and not ferrous enough to hold down on a surface grinder.  Made it so that each ring needed to be heated first for a friction fit onto the mandrel, but worked fine for removing anywhere between 0.1mm and 0.3mm from the face of each. This now gives me 0.1mm clearance for each ring within the cylinder/head channel. All checked, and all seating nicely now.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

Whilst down at SB Developments, I also turned myself a gudgeon pin spring clip insertion tool.....and sincere apologies for the blatant plagiarism of the Stomski Racing one

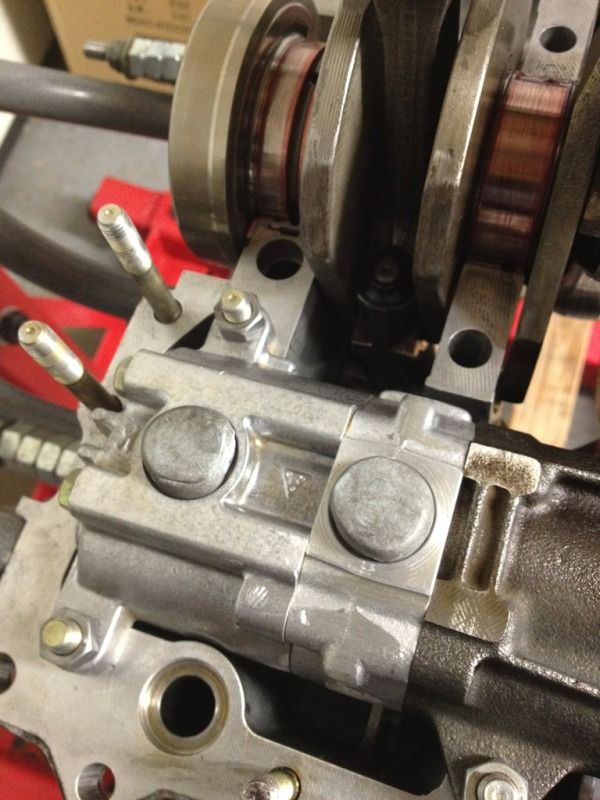

but I kinda needed it straight away over the May Day Bank Holiday w/e. but I kinda needed it straight away over the May Day Bank Holiday w/e. More progress; the rods were installed onto the crank - all using my stretch gauge, no guesswork here.  Then time for some more checking. Conscious that Chris @ TK had highlighted a possible issue with oil pump seal thickness, it made sense at this stage to do a plasticine (well, Blu-Tak) assembly, and see if my Victor Reinz items would be suitable.   The plasticine dimensions I got were: RH Case feed = 7.96mm LH Case feed = 8.68 -> 8.75mm LH Case scavenge = 8.76 -> 8.85mm Case bridging seal = 8.51 -> 8.65mm The green LH case seals I got in the gasket kit ranged between 9.45mm and 9.48mm, with light drag between the vernier calliper jaws. The brown RH case seal measured @ 8.56mm So, all looked to be okay, with sufficient thickness to squash when the pump is installed. Next job was to install just the intermediate shaft and oil pump to make sure it all rotated smoothly on it's own. Worked first time, no probs at all. Fitted the distributor bung into the LH case - blimey, with Loctite Retainer, that took a fair wallop (plus heat on the case and a frozen bung) to get into place. Not a problem with with the dimensions, purely the "grab" factor of the retaining compound, which I hadn't appreciated would be so immense. Anyway, it's in now, never to come back out. Time to seal the crankcase halves up!

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

And just when I thought I had all the sealants I cold possibly want for this engine project, I stumble upon this thread!!!

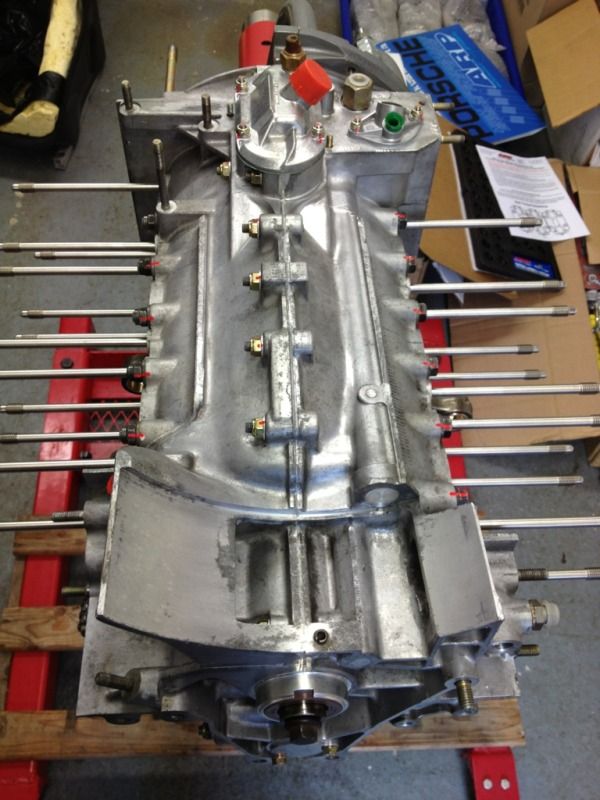

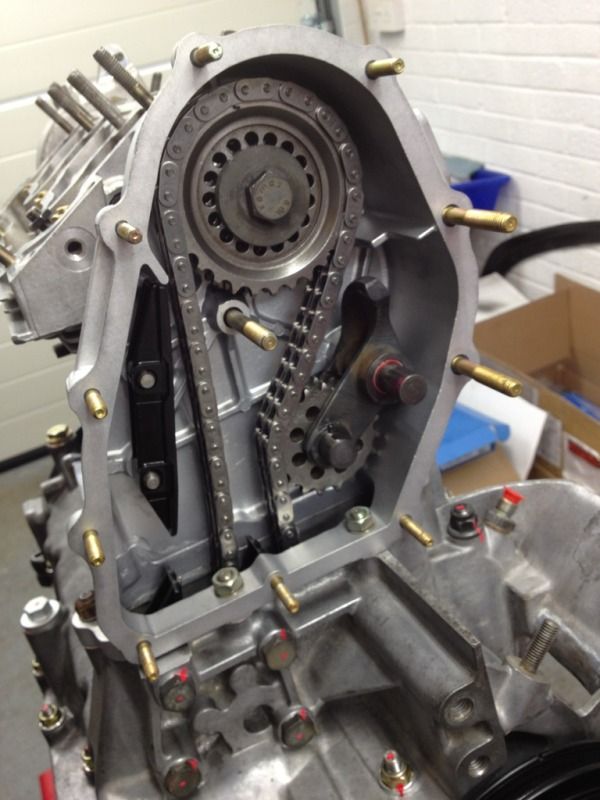

A few cups of tea later, plus an unhealthy amount of paranoia for my first 911 build, I then decided to order some Three Bond for the #8 and outer case flanges....just hit the "complete order" button when some advice came through. Doh! Having spent another £50 on these two products, I confess to wanting to bloody well use it and get my moneys worth! Now, the sealant used for the outer flange is 1194 (now called 1184, if anyone's about to buy some - I managed to get one of the last tubes of the 1194), and it has a set time of 1 minute!!!  Time to try some out on a scrap piece of aluminium. With the temp/humidity that day, I timed it that the compound was still very much workable at 5mins, but had skinned at 8mins. Did the same for the 1211 (which I used for the #8), but this was fine for at least 30mins working time (as it describes in the instructions) Loctite 574 (case through bolt webs) as we know is anaerobic, so not too much to worry about there.   New fasteners all lined up, crank then installed, inter shaft installed, chains on, home-made tools used to support rods and chain...another final clean on the mating surfaces with brake cleaner and then IPA.....time to get it built. Now, I decided to bolt this little lot together with the case bolts but not their seals. I wanted to really take my time on making sure the o-ring seals were fitted properly, not rush them as I would need to, in order to seal the case in the curing time I had. Leave it for 24hrs, then remove each bolt one-by-one and re-install with the o-rings and silicon grease. After a frantic hour of prep and spannering, ended up with --->  And I have to say, shaking but buzzing! A healthy but not excessive amount of liquid squirt-out of the 1194 from the flanges confirmed to me that I'd beaten the clock with that. Same for the #8, and I could see small but consistent signs of the 574 also being displaced. Big. Sigh. Of. Relief. Beer was consumed.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

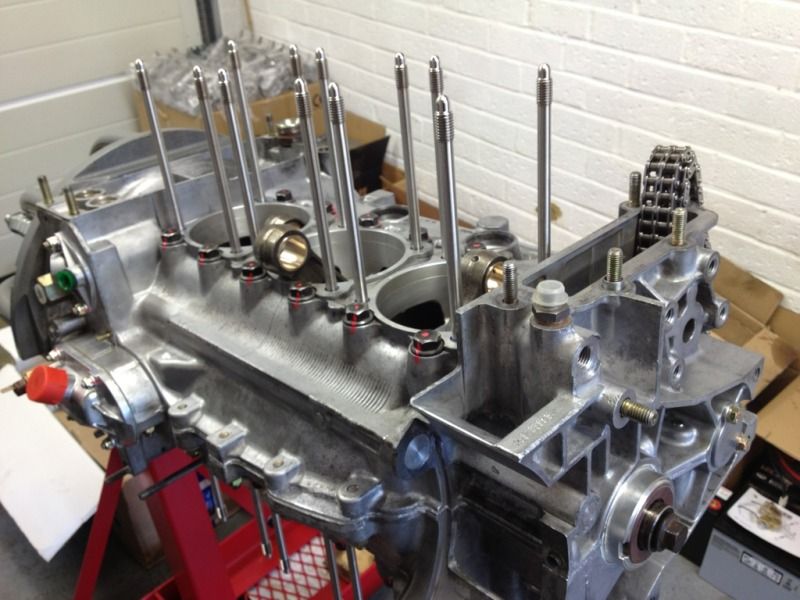

Time to start emptying the storage bags and re-fit clean stuff! Yipee!

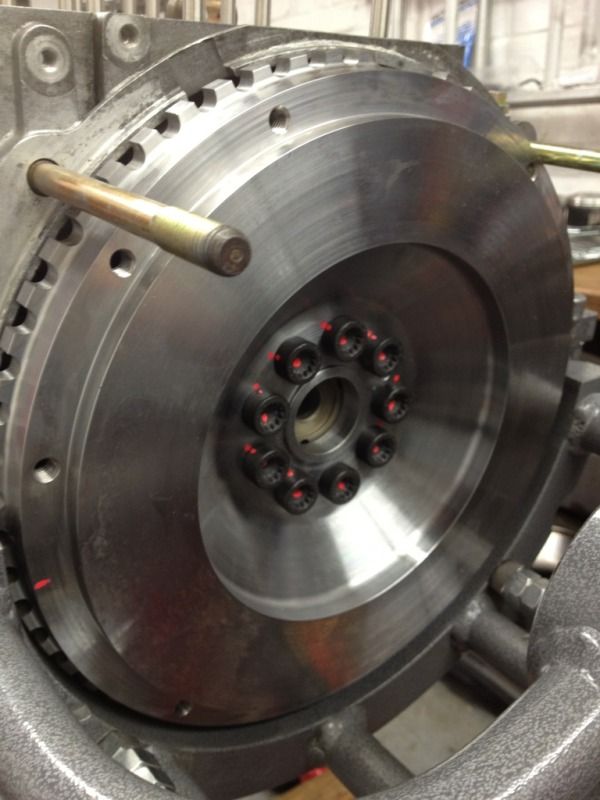

Crankcase breather and thermostat housing were first. Stupidly I then fitted the intermediate shaft cover, then realised it needed to come back off for the parallelism checks...newb mistake! ARP head studs fitted, all to the same height     Time for a big ticket item to get bolted on...the new flywheel, courtesy of TK Chris. 964 RS single mass unit, and it's SO much lighter...couldn't resist a quick weigh-in.... The old DM flywheel (perfectly good by the way...coming to an eBay near you soon)  And the new one--->  Height difference -->  7.2kgs lighter!!!! Less than half the weight, that's going to pick up so nicely, but more importantly, it's got the 60-2 tooth timing marks I need for mapping.   Can't get the starter ring on yet, the nut stack on the engine mount is ever-so-slightly stopping it from going on. The clutch plate, coming later on in the build, is a Sachs 997 GT2 item, iirc >850Nm capability. Perlenty.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

Pistons & Cylinders

Next up was to install the pistons into the cylinders, then fit them onto the rods - all in preparation for a dummy build to check valve clearances.

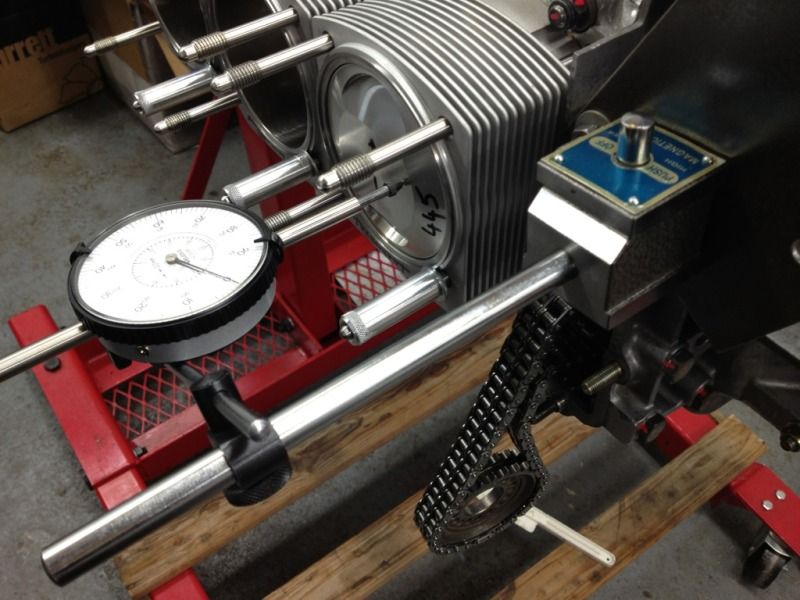

Used my new ring insertion tool; mixed success....some pistons it went in first time beautifully (cue smugness) but other times it was a right pain - probably a knack that I haven't quite got. Yet. And then a clock check to mark TDC....   I got the following dwell period --->  Ignore the "+" looking biro mark, that was an error. Which I then repeated onto some black marker pen marks on the teeth of the flywheel (great idea Matt!), which gives a larger resolution to be able to get it spot-on in the middle -->  That's just a buildup of marker pen ink, not a damaged tooth...the scribe mark is right on the RH edge, then one in the following "gap"

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

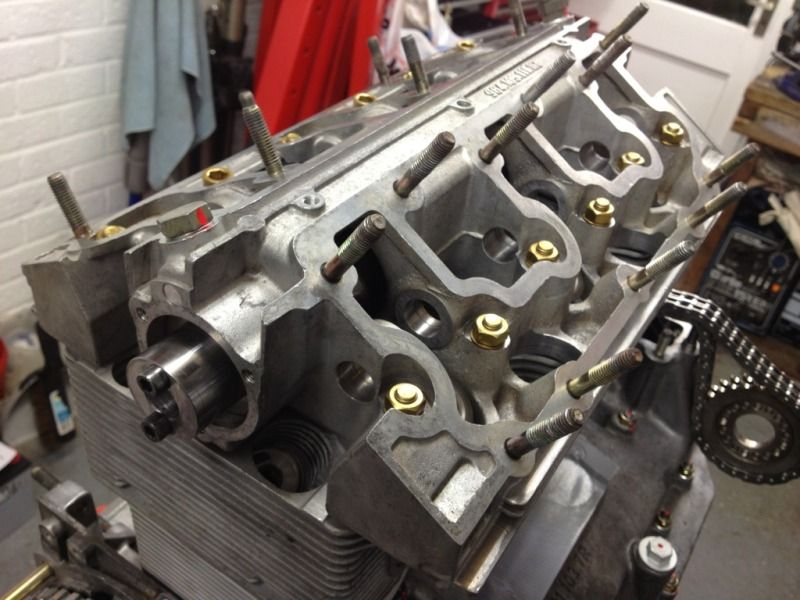

Next was to drop the heads on, torquing them up to the specified 38lb/ft that ARP specify.

Have to confess to having a mild heart attack late one evening, where I hastily put a straight edge across all three heads to check levels (I have no idea why I did this...put it down to excitement), and found a 0.12mm gap under #1 and #3!! Clearly the copper cylinder gasket wasn't squashed sufficiently. Once torqued they are now perfectly flat.  Cam carriers next--->   (sprockets just placed onto camshafts to save them banging about)

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Registered

|

Looks like I am just behind you. Did you install the ARP studs with "Loctite" or dry? Also, what are you going to do about final torque of the head nuts as ARP recommends 38 ft-lbs?

edit: looks like you went with 38 lbs, LOL. PS: like the wall art.

__________________

Steve Sapere aude 1983 3.4L 911SC turbo. Sold Last edited by sjf911; 05-14-2012 at 06:01 PM.. |

||

|

|

|

|

Kartoffelkopf

|

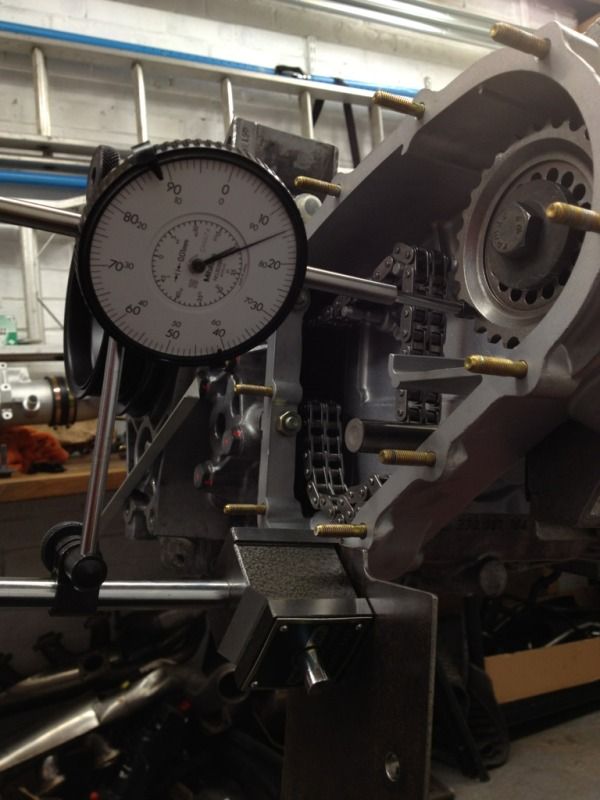

Next job, to check parallelism of the sprockets, plus the axial runout.

I made a very quick and simple mount to clamp the straight edge to, against the front of the crankcase. Bolts into one of the intermediate shaft cover bolt holes, and just means I have two hands free to use the vernier against the sprocket faces. With a little fiddling, I've now got the dimensions within spec. Of course, I'm now using new cams, so this definitely does need to be done. I noticed when re-assembling that the shims had slight burs, so took the opportunity to flatten them a little against some wet-and-dry stuck to a machined flat surface -->  Next up is the axial runout of the cams. All within spec @ 0.15 (LH) and 0.14 (RH)  Then a clean-up and installation of the chain tensioner wheels --->   And finally this evening, installed #1 inlet and exhaust rockers back into the cam carrier (without the RSR seals for the time being, don't want to risk tearing them) --->  Probably a few things I've forgotten this evening, but you get the idea of where things are up to...finally looking like an engine again!!!

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

Quote:

I used Loctite 242 to fix them, as they're not bottomed out on the crankcase. Left it overnight to do it's thing, then put the heads on....then iirc, left another night before torquing them up, giving the 242 plenty of time to lock the studs. You do actually feel an amount of what feels like slip when doing the nuts up....in fact, I thought the studs had rotated, but upon checking my tell-tale paint pen marks (glad I did them!) they were all absolutely in place, it was purely the stiction of the washer/head and thread interfaces. ETA: yeah, it's a "blokes" garage...gotta have some totty to look at whilst spannering

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

A point of clarity....

It's just occurred to me that I perhaps had inadvertently implied something that isn't correct!

Back in post #82, I said --> Quote:

Which has "TurboKraft" written on the tops of the cylinders. I just want to point out that although purchased through Chris @ TK (hence the marker pen), I did ask for them to be sent directly to me from LN, so the "snag" has absolutely nothing to do with TurboKraft, these were shipped directly to save time. Just wanted to be clear

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

Trial cam timing

Okay, so a few hours in the garage this evening to try my hand at cam timing. This isn't the final time-up, just a few dummy runs so that I can then check valve clearances.

One thing I hadn't done up to this point, was simply to rotate the crank a few times. Pins not inserted into the vernier pulleys just yet, so no valve actuation.....it all felt very smooth. Strangely satisfying. Followed the documented procedure for the milder cams, outlined in Waynes book. Cam dots rotated to vertical (checked with a plumb line no less!), crank positioned smack bang in-between the two TDC dwell markings, etc, etc.  Placing the DTI was a little bit of a sod. I'm using a rather large 0-50mm dial, so it has not only long travel, but a very big gauge. For this reason, I'm mounting onto a steel plate using a mag base.  The VERY narrow flat platform on top of the Schrick retainers also meant it was a fiddle to get the DTI aligned perpendicular in both planes, and sitting on this face. Timed it up to 1.36mm @ 0.1mm lash, i.e. full advance. The bit that messed up the first attempt was when I then removed the vernier pin (in order to rotate crank back to Z1)....the cam jumped around significantly, which I wasn't expecting, so missed how much it rotated. Attempt #2. It did do the same, but I was expecting it this time; rotation equated to about 0.3mm of lift, so I manually rotated the cam back again using the oil pump drive bolts at the back of the cam. Moved the crank back to absolute TDC, re-inserted pin, tightened the crank bolt and rotated everything 720 for a check. I'm sure there are people squirming at this method (!)...anyone know a way of preventing the cam springing around when removing the pin? Not bad for the first complete attempt, 0.03mm "out", giving me a lift of 1.33mm. Tomorrow night I'll have a go at the RHS, and see if I can get the two banks in sync. Then time to check valve clearances.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

|

Kartoffelkopf

|

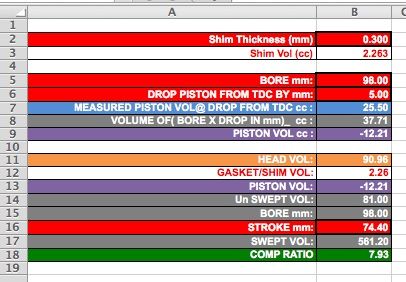

Was chatting with Chris Carroll earlier this evening, and realised that I completely forgot to post any details about compression ratios in last nights mass-update.

A few weeks ago I went down to SBD with the car crammed with new parts, so that I could do a dummy build on #1 to check CR's. All very straightforward, apart from when we came to cc the heads. The plexiglass lid we were using was a lot bigger than the recess in the heads on a 911, and we didn't have time to machine a nice circular disc, so a bit of guerrilla engineering, where we used 2 of the fire-rings I'm fitting, stacked onto each other and lightly sealed with some grease, onto which we then placed the lid ready for filling from the burette. Thank you Craig for the second pair of hands to hold it all nice and flat! The displacement of the piston dome was calculated by getting it to TDC, then dropping it by 5mm down the bore, then filling. The volume of a shim is only basic trig, so after all that we plugged the numbers into the spreadsheet, as shown here --->  So, using some copper base shims @ 0.3mm thickness, we get to a compression ratio of 7.93:1 That'll do nicely.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

At last, a few updates.....

Long time since the last update, so about time I downed-tools to scrawl some words on the progress. I'm now having to look back at the photo’s to remind myself of what happened next.

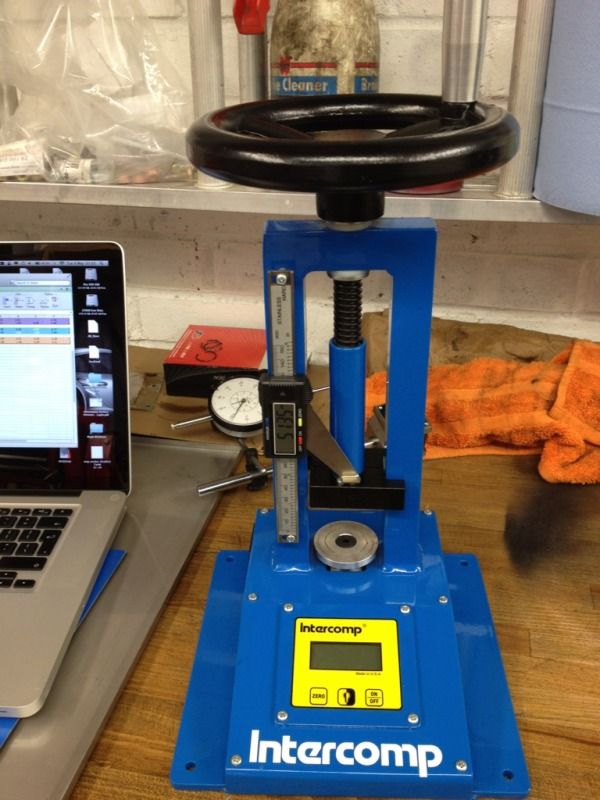

So, dummy build went fine, lots of practise with timing the cams. Had to pull a “through-the-night” stint to get it all broken down again, so that I could keep an appointment I had with my welder mate on the Saturday morning (his “project” day). I wanted to get the chamfered edge on the heads (near the injector reliefs, inlet side) built-up with weld so that there was more landing area for the gasket/inlet manifold. This meant that the valvetrain needed to be broken back down again, but this really was a job I wanted to do and not leave to chance.   Once all back and hand-finished to pretty it up, I confess to still not being happy with the valve spring install heights. Luckily, I was at a work conference with a bunch of German colleagues, so after commandeering one of them then drawing what I was trying to enquire about, we put a joint call into Schrick in Germany, with Marcus doing the translation. As it happens, the engineer who we got through to spoke very good English! We got the specs from him, with the all-important tolerances (bizarrely missing from the tech data for the valve gear I’ve got), then speaking with Chris at TK, we came up with a loading target for the valves. Then, by using the valve spring compression gauge at SBD, I was able to work backwards to calculate the shim heights  Rather than build up using a stack of stock sized shims, and only getting to within the tolerance, I decided to machine some solid shims and surface grind each one to the exact dimension, valve-by-valve.    Not the job of 5 minutes, and as my mate Matt and the guys at SBD will attest, I went around the loop a number of times (no OCD here, honest). This was mainly due to me not being comfortable with the repeatability of the measurements I was taking; being as accurate as I could, with a steady hand and the digital vernier, I was seeing far too much variation in the install heights during the rebuild. So, next job, make one of these:   This was far better, with entirely consistent and repeatable measurements. Very glad I spent the time re-doing what I’d already entrusted CTR Developments to do. Everything would’ve been far too soft had I left as-is, valves would’ve been opening under boost, etc. The Schrick/TK spring loadings were far higher than CTR had set-up to. For the love of God and all that’s Holy…..

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

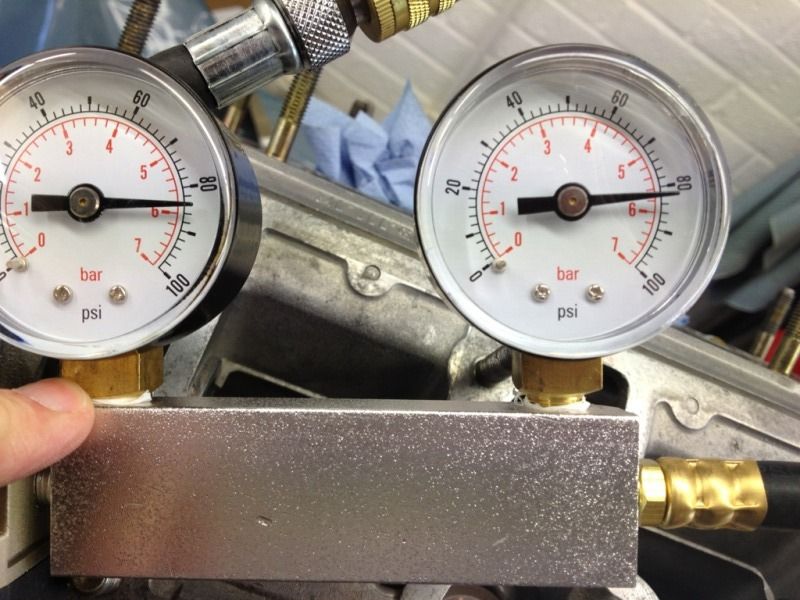

Right, heads rebuilt – finally – and ready for the next step. Time to reassemble the bottom end with both gudgeon pin retaining clips (very glad I made that insertion tool), reinstall the heads and then perform a leakdown test of each cylinder before assembling the cam carrier assy.

Ha-ha. More fun and games, as Chris @ TK will be chuckling about (laugh or cry, Chris, laugh or cry!). I knew the leakdown tester I bought last year was broken – see one of my first threads – but decided not to throw it in the bin, and to try and repair. It was only the gauges themselves that were faulty, the rest of the assembly is very straightforward, nothing to go wrong per-se, so long as the design was correct (this is the same generic unit as I think you guys can get from Harbor Freight, etc…mine was eBay, branded as a “Bergen” unit) Ordered some new, decent quality gauges, 2 x identical ones, then calibrated one to the other @ 100psi line pressure. (pic below wasn't using the 100psi, obviously)  Once assembled onto the tester manifold, I used it to test each cylinder. Frankly, the results I got were suspiciously out. The leakdown percentages were far too high (ie, far too good). Much as I’d like to think I built an engine with that good a leakdown, I really doubt it! I then borrowed a mates Snap-On tester…but….was also a little concerned that the needle on this gauge wasn’t zero’ing; it was only sitting back to 95% without any load. Looking at pictures of the same model on eBay, other units seem to have the same “problem”, others seemed to reset back to 100% as you’d expect. So, another set of reading that bore *some* correlation to the first set, albeit by 5% difference.  I admit to being a little spooked by these high readings; I did the usual light tapping of the valve with moderate pressure, to perhaps reseat the valves (and dispel any foreign bodies, should there be any). My gut reaction was that the majority of the air was leaking into the crankcase, but I was also seeing light inflation of the gaffer (duct) tape I sealed the inlet and exhaust ports with. I should say, that the audible volume of the leaking air was NOT loud, more a gentle whistling rather than air rushing out. Anyway, I decided to pull the heads….again….and strip them to check for adequate lapping in of the valve seats. Surprise surprise, not a great job was done by the outfit who built the heads. They were lapped, but the grey band was feint in places, varied in thickness on the seat and showed score lines, as-if there was crud in the lapping paste that was used. Either way, it looked a rush job and after re-doing one valve myself, and seeing the difference, I decided to strip the heads down – again – and lap everything in myself. One of the valve seats before:  ...and after re-lapping:  Far happier with the consistency of the lapping, everything was cleaned, re-assembled and built back onto the short-block. In fairness, using the Snap-On tester again, I saw small differences, but not really anything that was making the difference I hoped for. Hmmm. Leakdown attempt #3…..thinking laterally one evening, it dawned on me that the generic leakdown tester catered for 99.9% of cars that only run one spark plug. Being blessed with twin-plugged heads, I wasn’t limited to just trying to feed pressure into one plug hole and reading the leakage from the same port. So, assembling together a load of hoses and fittings that I'd accumulated, I double checked that both gauges read the same at 100psi “baseline” pressure off the airline. I then used the one of the 100psi gauges to monitor input air feed via a local regulator from the main air feed (into the inlet side spark plug). A Gunsons compression tester was then modified (removed the Schrader valve and the compression gauge, re-fitted the second new 100psi gauges). This was used in the exhaust side plug hole. Very simply, air was applied @ 100psi to one plug hole, then read off from the second plug hole using the second gauge. The difference between them is the % leakage. Four cylinders read 2%, with two of them reading fractionally less than 2% (if I were to estimate, then probably about 1.75%-1.8%) Far happier with these readings, not as optimistic as method #1, but more realistic than method #2 with the Snap-on. Time to get on and re-built the top end.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

Kartoffelkopf

|

No dramas with the rebuild, not a lot to report that everyone in this forum hasn’t seen dozens of times. Very satisfying knowing that each nut being torqued is being done for the final time. ThreeBond 1194 was used to seal the cam carrier to the heads.

RSR oil seals on the rocker shafts were fitted – no problems installing them, just a lot of care to avoid over stretching and tearing. Rockers for #1 and #4 inlets were installed, ready for cam timing. DTI setup again, timing wheels bolted on, chain tensioners fitted and clamped into place. After spending a few hours timing up the LH bank, 1-3, including re-indexing the verniers to get it precisely at full advance (1.36mm), the RH bank went surprisingly easily. Great, time to put in all of the other rockers and set the gaps. Or maybe not. I’ve no idea how it happened, but I’m glad I checked #1 valve gap a second time. To my annoyance, somehow, the gap was nowhere near the 0.1mm setting that I’d set it to the previous evening. Argghhh!!! Time to start all over again; remove the rockers and re-time everything. What an absolute pig – some cracking Anglo Saxon was spoken. Anyway, all done (re-done) the next evening, all gaps set, checked and rechecked (!!). Thankfully, I managed to carefully install all the rocker shafts and RSR seals dry, hopefully mitigating any chance of oil weeping.   Timing, after a lot of setting, checking, resetting, re-indexing, etc....1.35mm on 1-3 and 1.37mm on 4-6. Not convinced the stock vernier pulleys are the best design, too coarse an adjustment on the pins IMHO....nowhere near as good as the ones I'm using on my Vauxhall engine in the Westfield (which in fairness have the pins/holes set in a larger diameter than the Porsche ones, so has a finer range of adjustments)

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject Last edited by Spenny_b; 07-28-2012 at 03:51 AM.. |

||

|

|

|

|

Kartoffelkopf

|

Now for the fun part – bolting everything on.

I’d been thinking about how best to mount the cam position sensor, and opted to site it in the “usual” place in about the 5 o’clock position on what was the air pump pulley housing. The sensor and mounting was supplied by TurboKraft, so it came with a very nice pair of CNC machined mounting plates. The intention was to lighten the toothed belt pulley as much as possible and mount a steel hex head bolt in there to trigger the hall effect sensor. First job, back to my welding man to attach one of the CNC’d plates to the housing. At the same time, I fabricated a couple of covers to enclose the openings where the air pump belt used to enter/exit the housing. After a fair amount of sanding and grinding, then vapour blasting, the end result looks pretty good I reckon:    Another visit to SBD saw the pulley get even lighter!  …into which I’ll drill and tap for a mild steel pick-up….  Meaning I now no longer need the second CNC'd plate to space out the hall-effect sensor. This can now go directly into the housing, and I can set the 1mm gap with the length of the mild steel sender. As a result of the lightening mission, I now have an unusual coaster for the coffee table.  Because I'm running twin plugs on the heads, I needed to fettle the cylinder head temperature bracket so that it clears the new access holes.  Unfortunately, after everything has been powder coated, I’ve needed to modify the tinware that sits at the back of #3 to accommodate the head temp sensor (my fault, poor planning), but also to allow access to the lower spark plug on #3.   In addition, the hole cut in the exhaust valve cover also needed modification to elongate and allow a 14mm plug to be installed!....Another *fantastic* piece of work by CTR; can’t even get a bloody hole right. (…and yes, I do want to fit the same size plugs to the top and bottom of each head)  These items are still back over with the powder coating company, but there are other jobs to be getting on with.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject Last edited by Spenny_b; 07-27-2012 at 06:28 AM.. |

||

|

|

|

|

Kartoffelkopf

|

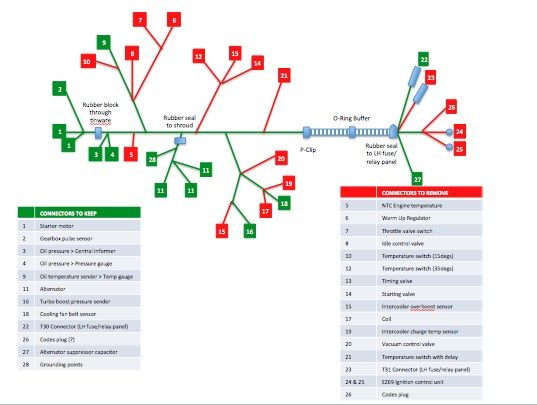

Anyway, less of the negative stuff….overall, I’m really pleased with how it’s coming along:

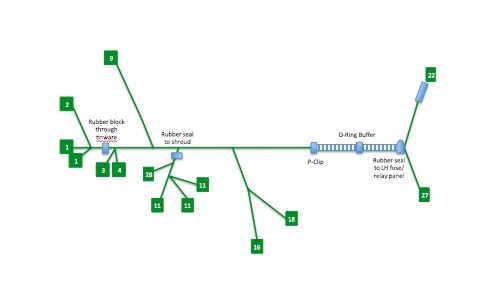

• Cooling fan strap was carefully fitted • Engine shroud modified to accommodate the Carrera intake manifold phenolic blocks • Power steering drive pulley refurbished • PS pump brackets replaced • PS housing fitted • PS pump now re-installed • A/C bracket in place with the newly plated exhaust silencer bracket fitted   Then onto the engine wiring loom. My dilemma was whether to modify the existing loom, removing the whole of the T31 connector and its associated wiring, then re-covering with heatshrink, or whether to try and source all the connectors and fittings, then make a new loom. After looking up the price of a new loom, and considering mine (once cleaned) was in immaculate condition and hasn't gone hard and cracked with heat, I decided to not hack this about and save for a rainy day. A few PowerPoint diagrams later and I had a plan of what I needed to make.    I sourced all the parts I needed, ordered all the thin-wall wiring and decided to uprate the cable between the starter motor and alternator, as well as from the alternator to the suppressor. A day sat quietly making it (not my first loom, have designed and made the complete loom for my Westfield, plus many alterations to looms on other cars), and voila, quite a smart looking bit of wiring…and a lot lighter and less complex. Original loom:  New loom (unterminated):

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

|

Kartoffelkopf

|

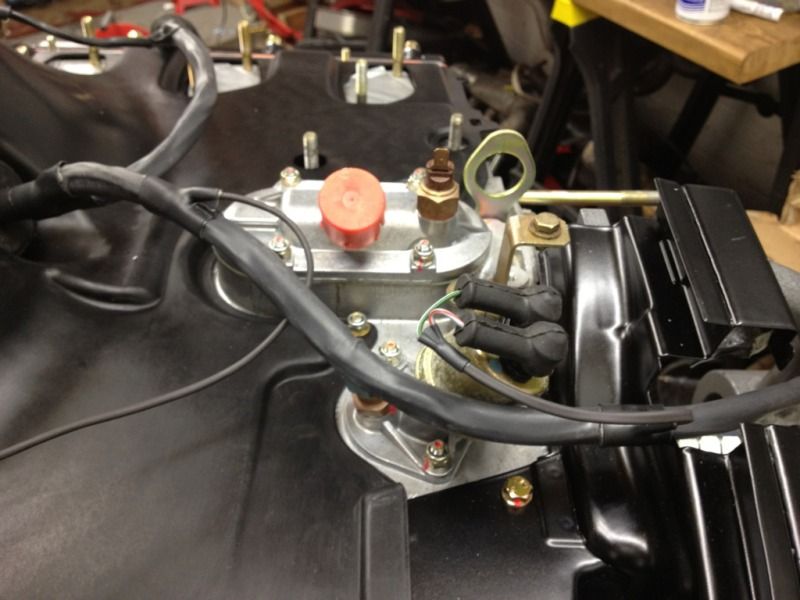

A trial fit of the loom, then some careful finalising of cable lengths (especially items like the alternator and starter motor), a little more heatshrink then time to hook it up to the alternator.

A little bit of patience needed to route the loom and replace the nose cover of the alternator, bolt down the ground connection to the crankcase and re-fit the alternator/fan assy into its strap. A new cooling fan belt now shimmed and fitted:  ...as is the crank position sensor (fitted into a new bracket, the old one broke):  Next job, bolt on the intake manifold! Woo-hoo!!

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject Last edited by Spenny_b; 07-27-2012 at 06:29 AM.. |

||

|

|

|

|

Kartoffelkopf

|

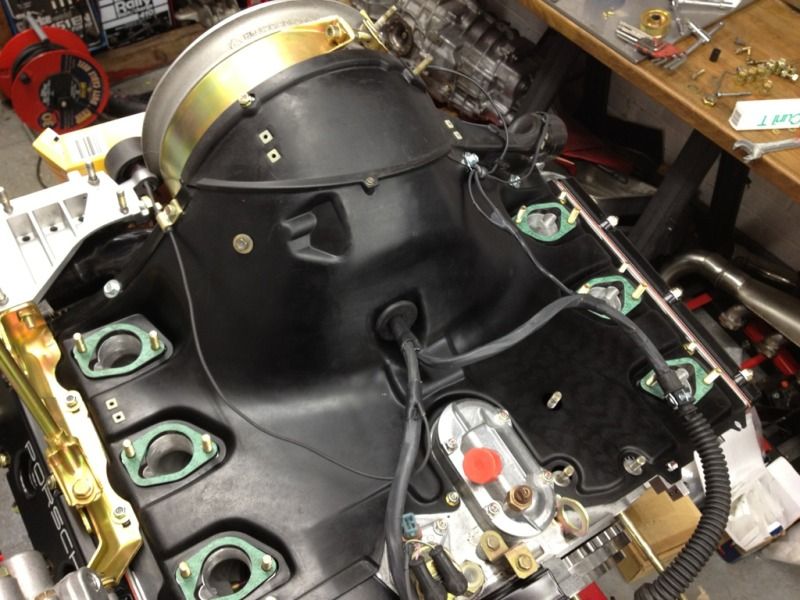

Despite me assembling it a few months ago (see previous post), I’d spotted some of the vapour blasting residue (like very fine castor sugar) that had dried and collected under where the manifold was sitting in my office. Time to strip it down, and scrub with hot soapy water. A quick re-assemble after drying thoroughly, and it’s ready to go onto the engine.

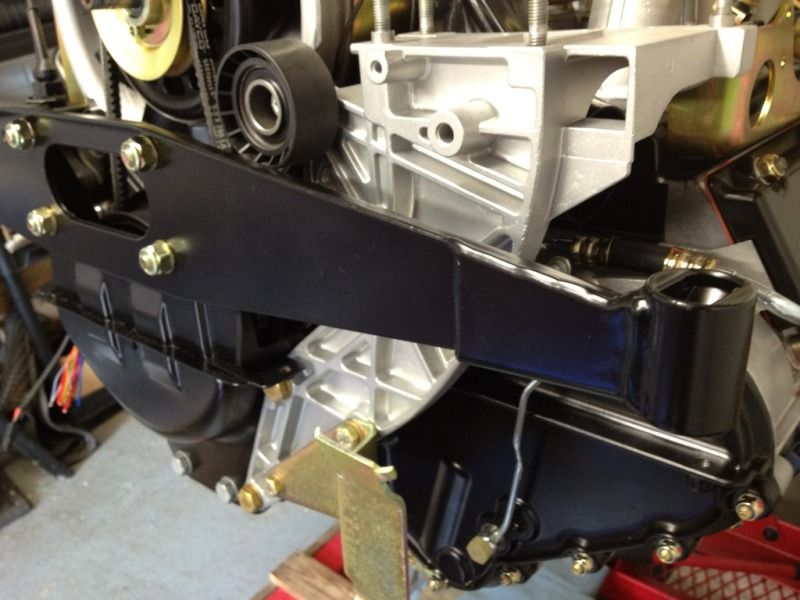

Another order into my OPC for some bolts and other sundries that were just way beyond being salvaged with re-plating, and I was able to then bolt on the engine mounting hardware:   Here you can see the extra strengthening I've fabricated and welded in. …and that’s pretty much where I’m now up to. Tonights job is to solder on the T30 connector, now I have a new set of sockets for the connector. Just waiting for some tinware and the 1-3 exhaust valve cover to be powder coated, then I can start looking at fitting headers and the new Garrett turbo. Once I can get that far, then it’s time to start fabricating to install the new twin scroll flange (T3) and twin wastegates. My new intercooler is being built over at TurboKraft – in fact it’s probably welded up right now, and possibly with the plating company for it’s anodised coating. Once I have this, I can fab the IC outlet pipe > intake butterfly, fitting the various bosses I need for dump valves, sensors, etc.

__________________

1993 (MY92) 964 Turbo 3.3 - Horizon Blue - Follow my 964 Turbo project here... http://forums.pelicanparts.com/911-engine-rebuilding-forum/626572-964-3-3-turbo-efi-conversion-using-syvecs-life-racing-engine-management.html On Instagram (along with other stuff) as @spenny_.b #spennybengineproject |

||

|

|

|

|

|

|

| Tags |

| 964 c4/c2/turbo , efi conversion , life racing , syvecs , turbokraft |